Putamen pattern cellulose stainless steel powder compounded microballons and the preparation process thereof

A technology of stainless steel powder and composite microspheres, which is applied in the preparation methods of peptides, chemical instruments and methods, and other chemical processes, etc., can solve the problem of not developing a spherical expanded bed adsorption matrix, and achieve regular shape, increase matrix density, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The steps of the preparation method of core-shell cellulose / stainless steel powder composite microspheres are as follows:

[0022] 1) Prepare composite water phase

[0023] Mix stainless steel powder superfine particles and industrial cellulose xanthate viscose at a mass percentage of 5%-40% at room temperature, stir evenly, heat up to 25-35°C, and continue stirring for 30-45 minutes;

[0024] 2) Suspension heating and solidification into balls

[0025] Stop stirring, add oil dispersion phase and surfactant, then start stirring, suspend and disperse at 25-35°C for 30-60 minutes, heat up to 90-95°C, keep warm for 1.5-2 hours, the viscose solidifies to obtain microspheres;

[0026] 3) Regeneration of homogeneous microspheres

[0027] The solidified microspheres are filtered out from the oil phase, washed with 1 to 2 times the volume of benzene to remove the oil layer, and then regenerated with 2 to 3 times the volume of methanol, ethanol solution containing 30% acetic a...

Embodiment 1

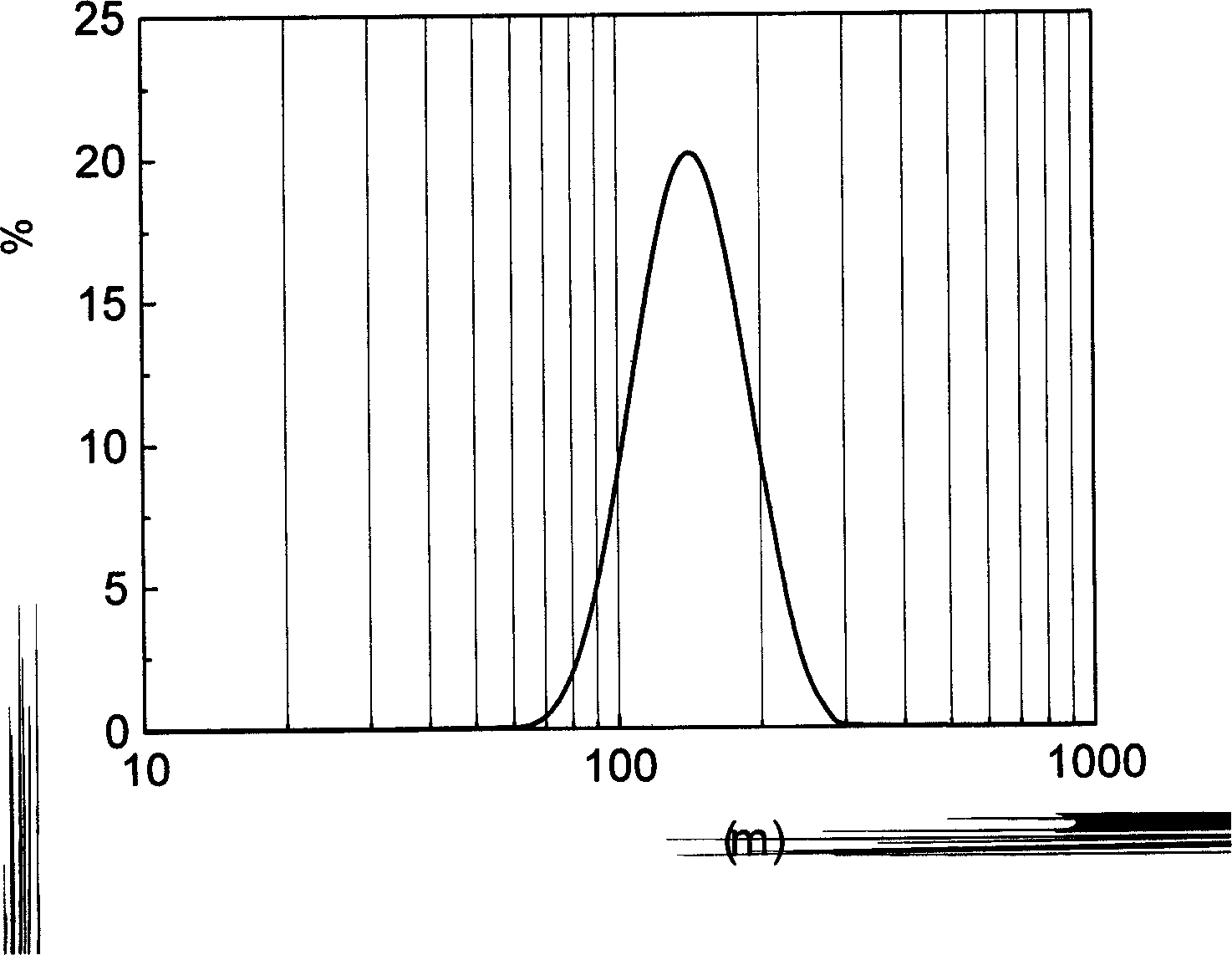

[0037] Add 100g industrial viscose (containing cellulose 8.2g, CS 2 3g, NaOH6.2g, viscosity is 6800cSt) and 20g stainless steel powder, be warming up to 30 ℃ and stir for half an hour; Stop stirring, add 600mL by the mixed oil phase of pump oil and chlorobenzene preparation (pump oil: chlorobenzene=4: 1, Mass ratio), adjust the stirring speed to 650rpm, keep the speed constant, suspend and disperse at 30°C for 45 minutes, heat up to 90°C within 15 minutes, keep warm for 1.5 hours, and solidify to obtain yellow-white microspheres; filter the microspheres from the oil phase out, washed with 150mL of benzene for 1 hour, 200mL of methanol for 1 hour, 200mL of ethanol solution containing 30% acetic acid for 1 hour, washed with tap water three times, and wet sieved to obtain 42mL of white balls with a particle size between 60 and 200μm. , with a density of 1.2g / cm 3 .

Embodiment 2

[0039] Add 100g of the above-mentioned industrial viscose (composition is the same as Example 1) and 20g stainless steel powder in a 1-liter three-necked flask, heat up to 35°C and stir for half an hour; add 450mL of mixed oil phase prepared by pump oil and chlorobenzene (pump oil: chlorine Benzene=6:1, mass ratio) and 0.9g oleic acid, adjust the stirring speed to 600rpm, suspend and disperse for 1 hour at 35°C, heat up to 90°C within 15 minutes, keep warm for 1.5 hours, and solidify to obtain yellow-white microspheres; The balls are filtered out from the oil phase, washed with 200mL benzene for 1 hour, regenerated with 200mL methanol for 1 hour, and regenerated with 200mL 10% sulfuric acid solution for 1 hour, washed with tap water three times, and sieved in a wet state to obtain a particle size between 60 and 300 μm. 48mL of white balls with a density of 1.2g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com