Process for producing nano calcium carbonate by ultrasonic cavitation technology

A nano-calcium carbonate, ultrasonic technology, applied in the direction of calcium carbonate/strontium/barium, chemical/physical/physical-chemical process of applying energy, etc., can solve problems such as inability to implement, lack of implementation features, etc., to achieve low production cost, convenient computer Automatic control, the effect of shortened preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

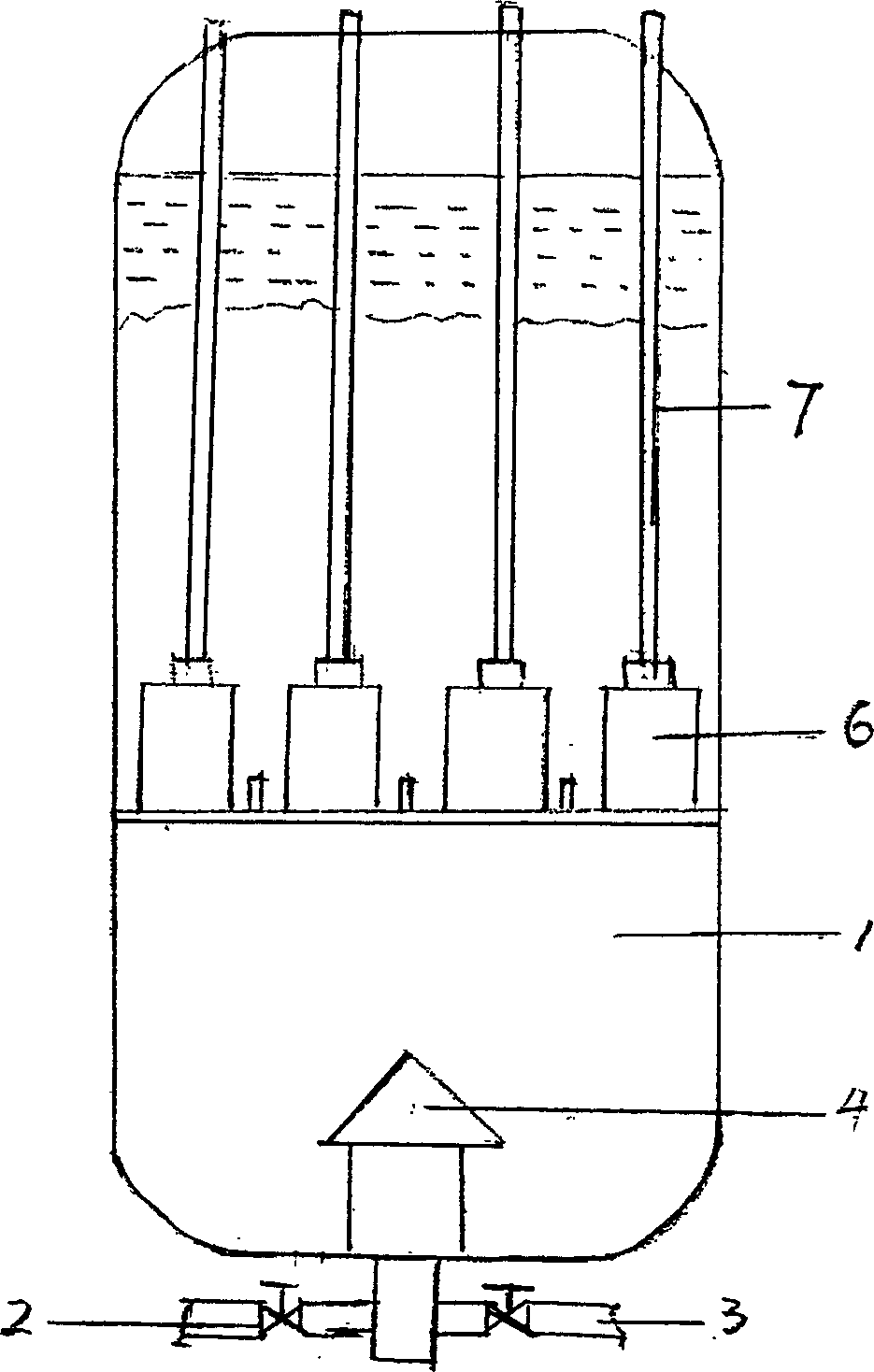

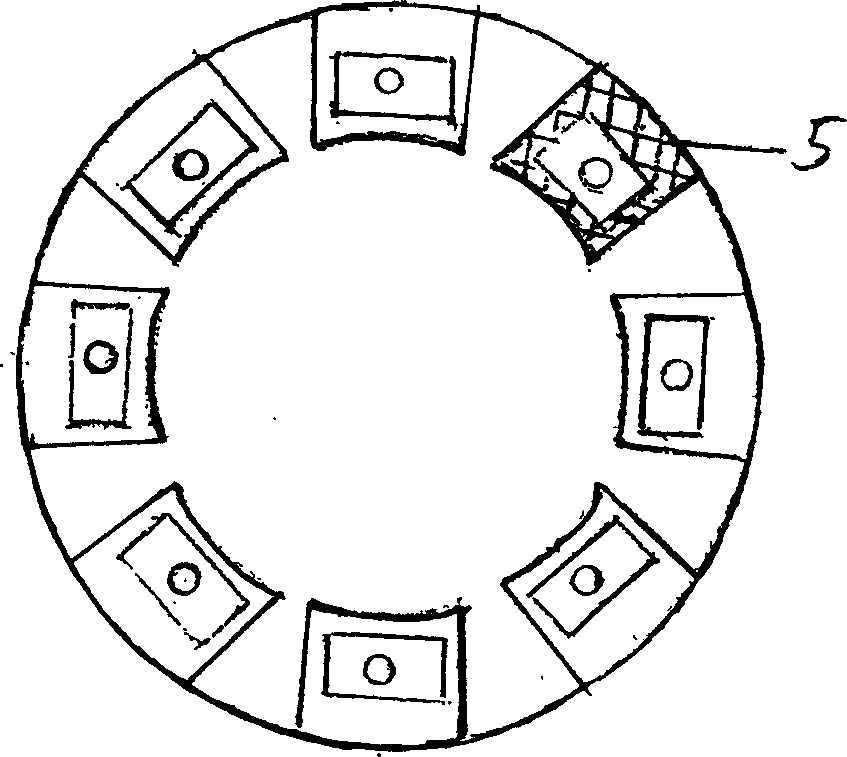

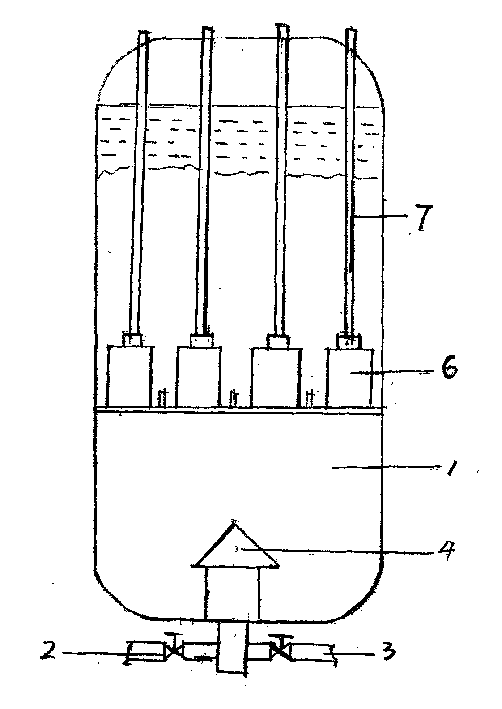

[0010] Example 1: Limestone is calcined at 1100°C in a vertical kiln to obtain calcium oxide and carbon dioxide gas. The carbon dioxide is sent to a carbon dioxide gas storage tank through an induced draft fan. Weigh 1 ton of calcium oxide and 10 tons of water, and hydrate in the digester. The volume of the digester is 20m 3 , equipped with 1 set of ultrasonic pulverizer, the product model of ultrasonic pulverizer and matching waterproof transmitter is: SC-7000W, the upper end of the transmitter is equipped with a sealed long stainless steel tube, the long tube must be led out of the equipment, and the cable of the transmitter is provided by The inner hole of the tube is connected to the ultrasonic pulverizer. The fixed net frame for installing the transmitter is set to be fixed on the inner wall between the inner wall of the equipment that must be equipped with ultrasonic waves and the stirring shaft in this process, and the upper and lower distances are 1 meter and evenly im...

Embodiment 2

[0011] Embodiment 2: when CaO is hydrated, the ultrasonic power is 6600W, the operating frequency is 17KHZ / second, and 12 sets of transmitters are prepared with a cavitation time of 40 minutes; Ca(OH) 2 When making pulp, the ultrasonic power is 6600W, the working frequency is 17KHZ / s, and 12 sets of transmitters are prepared, and the cavitation time is 30 minutes; during the carbonization reaction, the ultrasonic power is 6600W, the working frequency is 17KHZ / s, and the air mixture contains 35% carbon dioxide , the mixed gas flow rate is 22m 3 / min, the carbonization reaction temperature is 25°C. Prepare 12 sets of emitters for ultrasonic cavitation for 35 minutes, and the drying temperature is 200°C. Others are the same as in Example 1, and the crystal form is observed with a scanning electron microscope. The average particle diameter is 32 nanometers, and the diameter-to-length ratio is 1:10-15.

Embodiment 3

[0012] Embodiment 3: when CaO is hydrated, the ultrasonic power is 6800W, the working frequency is 16KHZ / second, and the cavitation time of 14 sets of transmitters is prepared for 35 minutes; Ca(OH) 2 When making pulp, the ultrasonic power is 6800W, the working frequency is 16KHZ / s, and 14 sets of transmitters are prepared, and the cavitation time is 25 minutes; during the carbonization reaction, the ultrasonic power is 6800W, the working frequency is 16KHZ / s, and the air mixture contains 38% carbon dioxide , the mixed gas flow rate is 33m 3 / min, the carbonization reaction temperature is 22°C. Prepare 14 sets of emitters for ultrasonic cavitation for 25 minutes, and the drying temperature is 240°C. Others are the same as in Example 1, and the crystal form is observed with a scanning electron microscope. The average particle diameter is 28 nanometers, and the diameter-to-length ratio is 1:9-17.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com