Method for synthesizing metal/ceramic composite coating by spraying and self-reaction composite powder on metal surface

A ceramic composite, metal surface technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve the problem of not being able to prepare coating on the outer wall of the workpiece, improve thermal shock resistance, enhance bonding strength, overcome brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

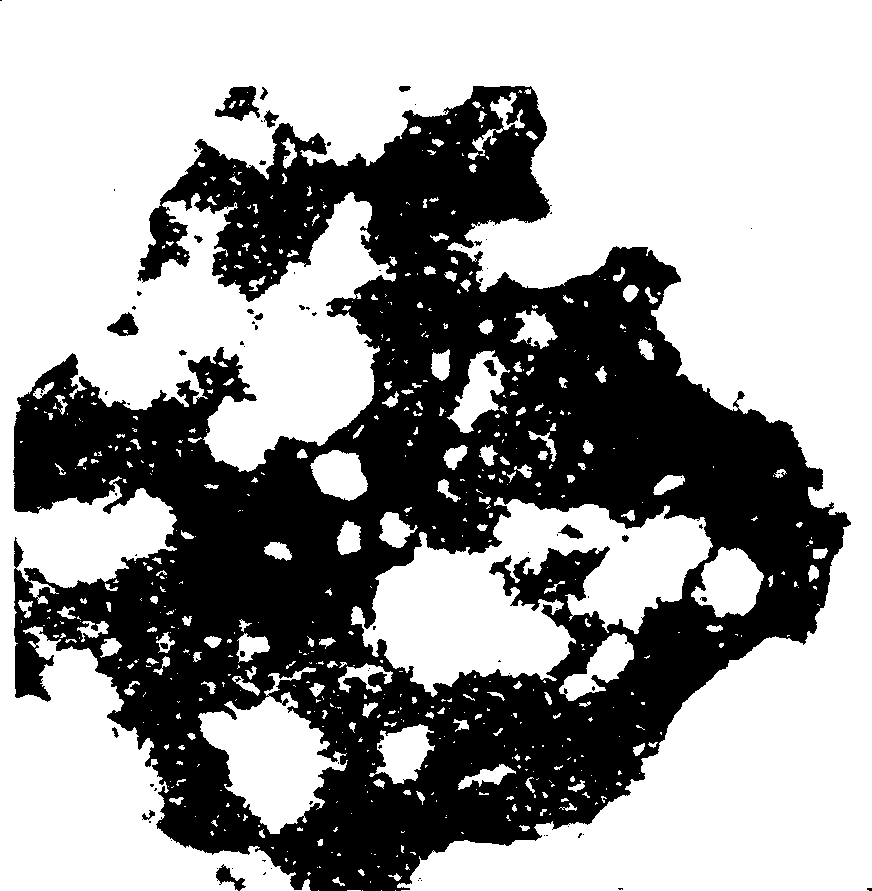

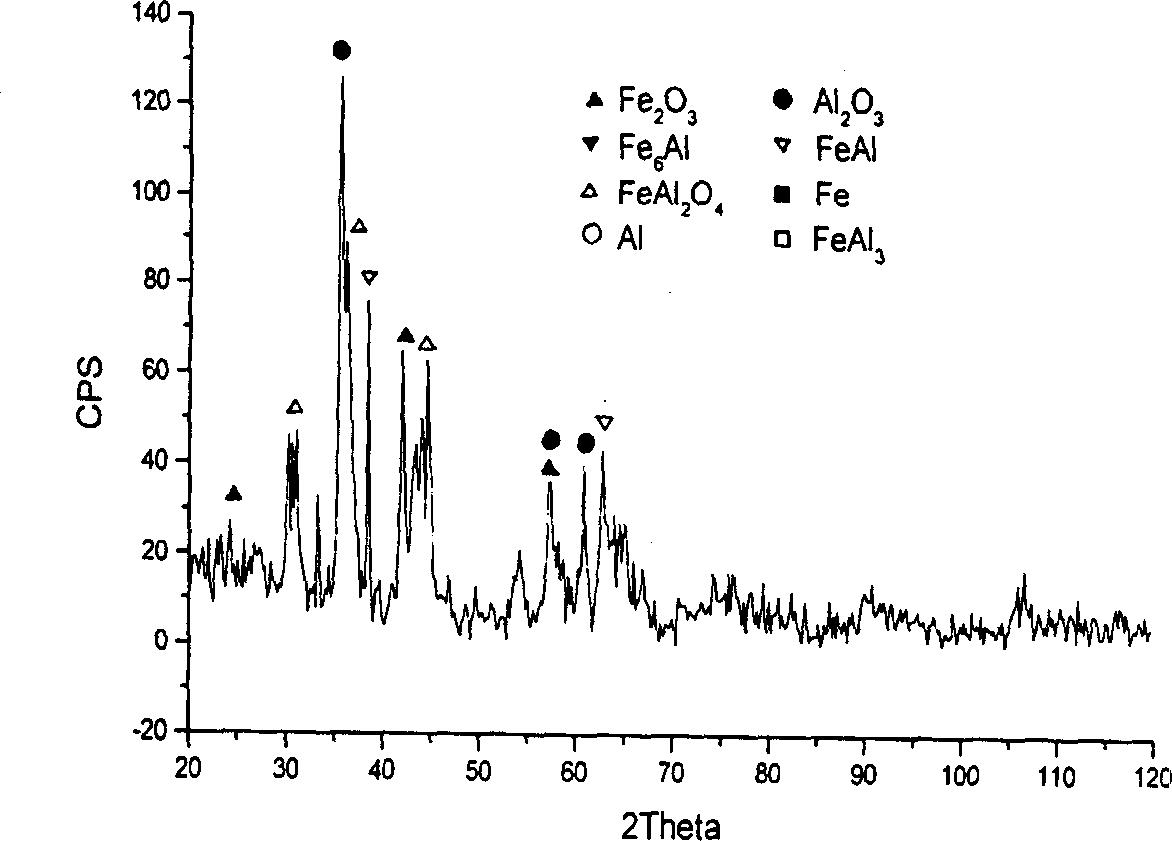

[0069] Example 1 Spray self-reactive composite powder on Q235 steel to synthesize a 1.2mm thick metal / ceramic composite coating

[0070] 1. Prepare 700g of self-reactive composite powder

[0071] (1) 1280g iron oxide (Fe 2 o 3 ) powder and 540g aluminum (Al) powder are put into ball mill, add appropriate amount of ethanol simultaneously, mix 20 hours, until stirring evenly;

[0072] (2) The mixed powder that stirs is dried;

[0073] (3) Add 250ml of adhesive polyvinyl alcohol (PVA) to the uniform mixed powder, and stir for 2.5 hours at the same time, until the mixed powder becomes a composite powder with large particles;

[0074] (4) Put the prepared large-particle composite powder into a drying box, and keep the temperature at 100°C for 20 hours until the particles are completely dry;

[0075] (5) Put the dried large-particle composite powder into a pulverizer to pulverize, and then use a sieve to screen the composite powder between -60 and +80 mesh for later use.

[007...

Embodiment 2

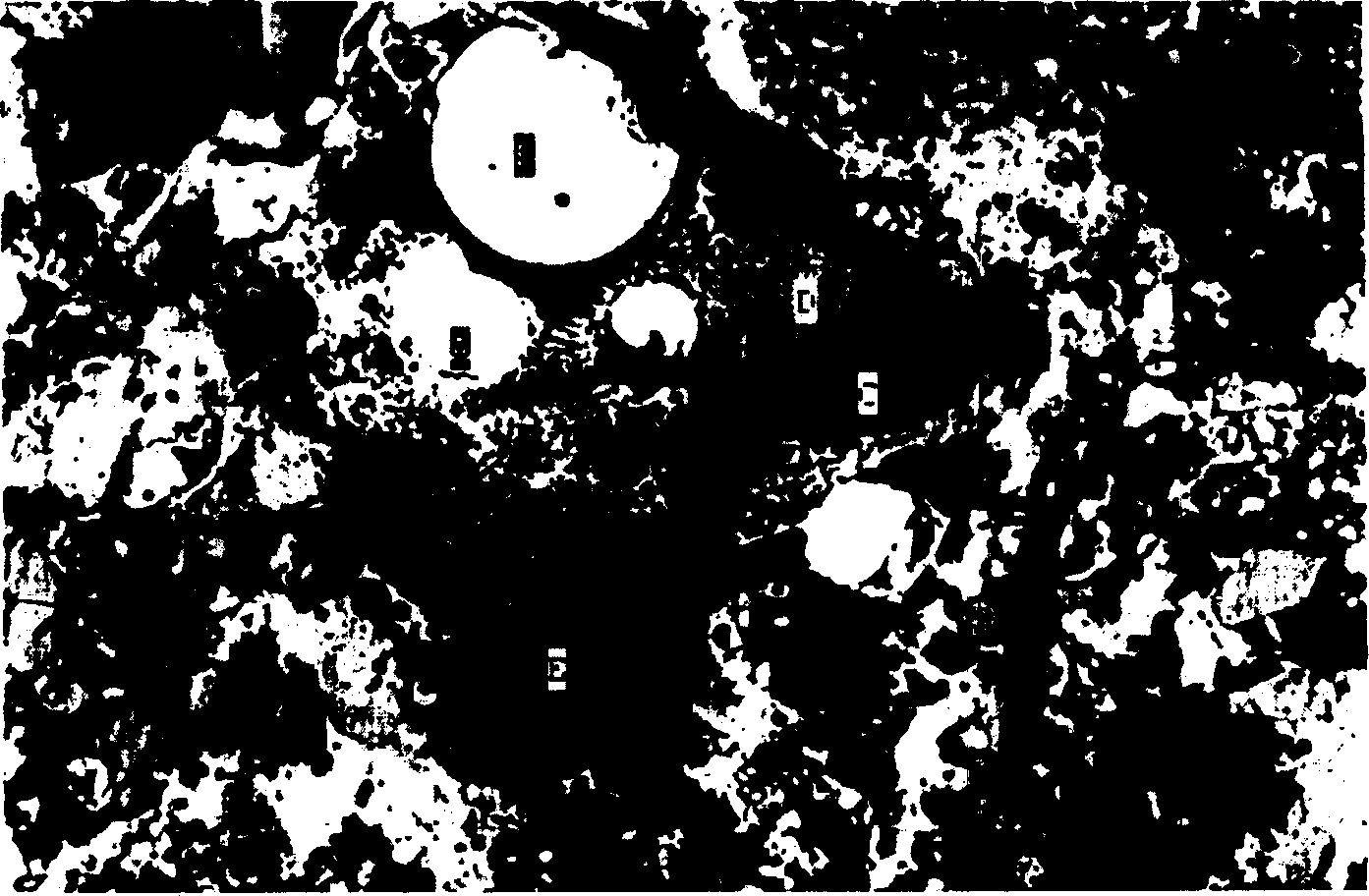

[0108] Example 2: Spraying self-reactive composite powder on low carbon steel to synthesize a 1.0-1.2mm thick metal / ceramic composite coating

[0109] 1. Prepare 600g of self-reactive composite powder

[0110] (1) 1120g iron oxide (Fe 2 o 3 ) powder and 470g aluminum (Al) powder are put into ball mill, add appropriate amount of ethanol simultaneously, mix 18 hours, until stirring evenly;

[0111] (2) the mixed powder that mixes evenly is dried;

[0112] (3) Add 220ml of adhesive polyvinyl alcohol (PVA) to the uniform mixed powder, and stir for 2 hours at the same time until the mixed powder becomes a composite powder with large particles;

[0113] (4) Put the prepared large-particle composite powder into a drying box, and keep the temperature at 150° C. for 1 hour until the particles are completely dry;

[0114] (5) Put the dried large-particle composite powder into a pulverizer to pulverize, and then use a sieve to screen the composite powder between -120 and +150 mesh fo...

Embodiment 3

[0147] Example 3 Spraying self-reactive composite powder on low-carbon steel to synthesize a 1.0-1.2mm thick metal / ceramic composite coating

[0148] 1. Prepare 800g of self-reactive composite powder

[0149] (1) 1440g iron oxide (Fe 2 o 3 ) powder and 600g aluminum (Al) powder were put into the ball mill, and an appropriate amount of ethanol was added at the same time, and mixed for 24 hours until uniformly stirred;

[0150] (2) the mixed powder that mixes evenly is dried;

[0151] (3) Add 300ml of adhesive polyvinyl alcohol (PVA) to the uniform mixed powder, and stir for 3 hours at the same time until the mixed powder becomes a composite powder with large particles;

[0152] (4) Put the prepared large-particle composite powder into a drying box, and keep the temperature at 120° C. for 15 hours until the particles are completely dry;

[0153] (5) Put the dried large-particle composite powder into a pulverizer to pulverize, and then use a sieve to screen the composite powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com