Powder for forming enamelled plastics and its preparing process

A technology of powder and polyvinyl chloride, which is applied in the field of slush molding powder and its preparation, can solve the problems of poor melting performance and achieve good flow performance, satisfactory mechanical properties and excellent melting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

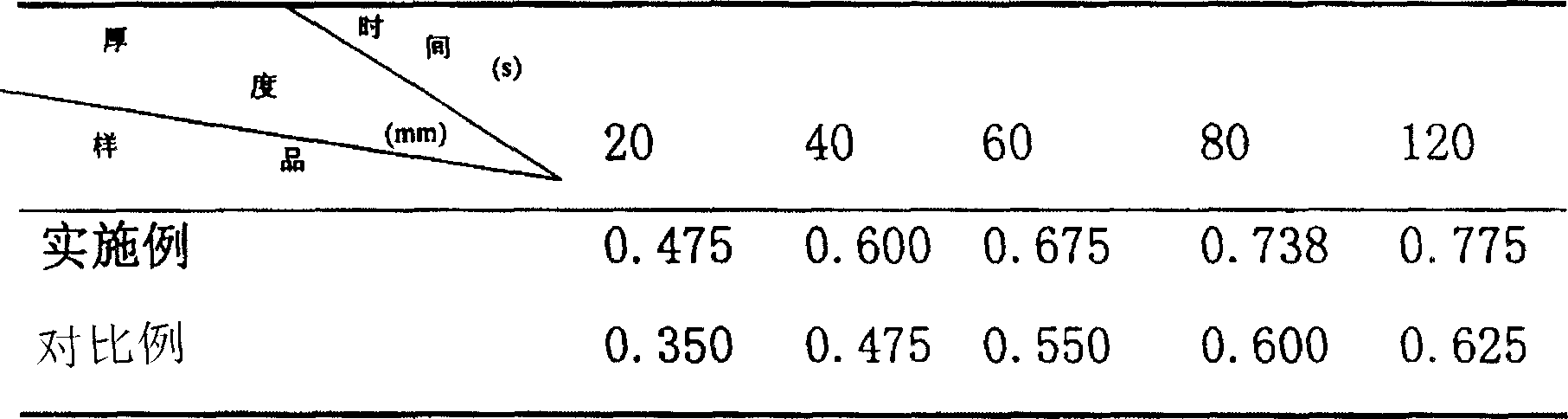

Examples

Embodiment

[0036] Add 40Kg of MPVC (the degree of polymerization is 1000), 1.2Kg of calcium stearate, 0.8Kg of zinc stearate, 120g of bisphenol A, 200g of DSTP, 20g of light stabilizer 144, and 20g of UV-326 into the high-speed mixer In, stir and heat up to 95 DEG C, add 25KgDINP, the epoxidized soybean oil of 2.7Kg, continue to stir and heat up, when temperature rises to 105 DEG C, stop heating, stop stirring, make polyvinyl chloride resin absorb plasticizer, 10 minutes ( After t1), the plasticizer has been completely absorbed. At this time, stir and heat up to 120°C, add 800g of carbon black, stir for 2-5 minutes, and discharge to obtain a fluffy powder. When the temperature of the fluffy powder dropped to 65°C, it was added to another high-speed mixer, and 6Kg of PPVC resin (polymerization degree was 1500) was added, stirred for 10 minutes and discharged. Sieve with a 40-mesh sieve to obtain the title mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com