Modular and cascade development method for underground in-situ conversion of oil-rich coal

A modular, oil-rich coal technology, applied in coal gasification, underground mining, mining fluids, etc., can solve the problems of reducing the comprehensive utilization of oil-rich coal resources, insufficient utilization of coal seams, and easy collapse of cavities, so as to improve resource utilization efficiency, improving resource utilization efficiency, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides a modularized and stepped development method for underground in-situ conversion of oil-rich coal, the method comprising the following steps:

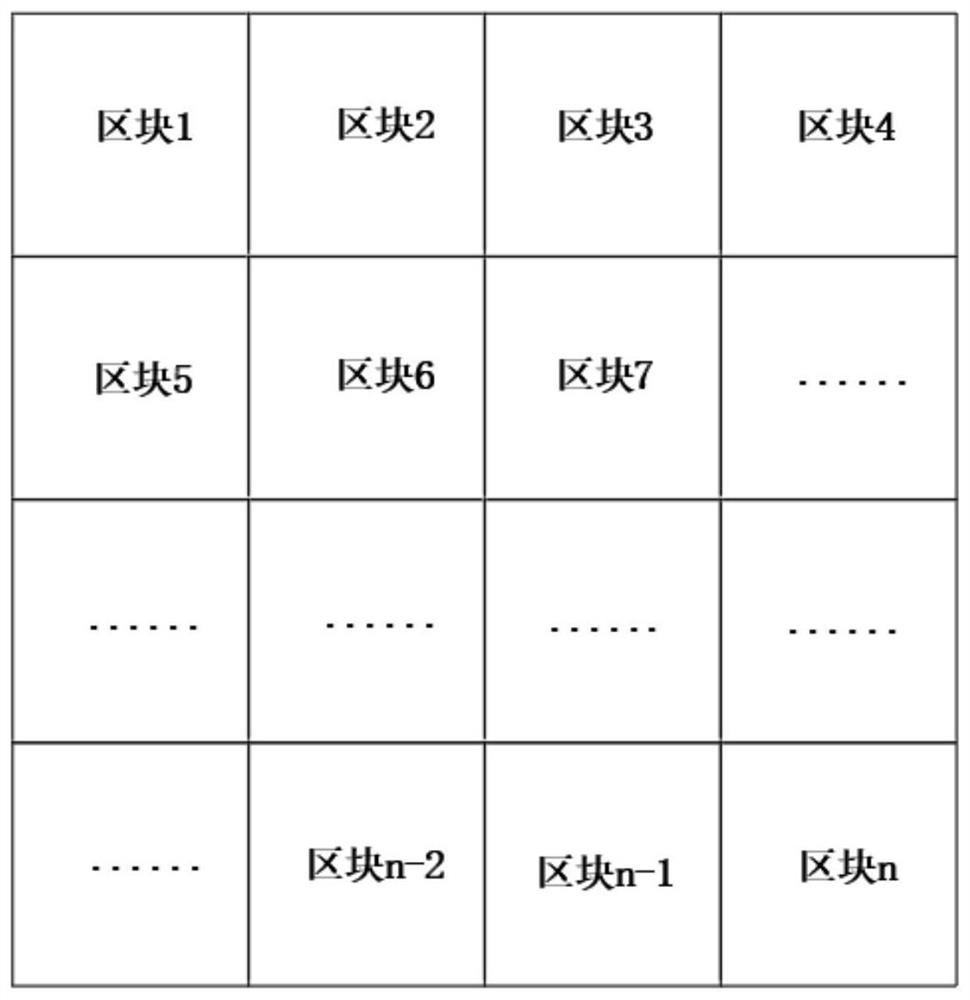

[0038] Step one, as figure 1 As shown, the oil-rich coal development zone is divided into multiple oil-rich coal blocks;

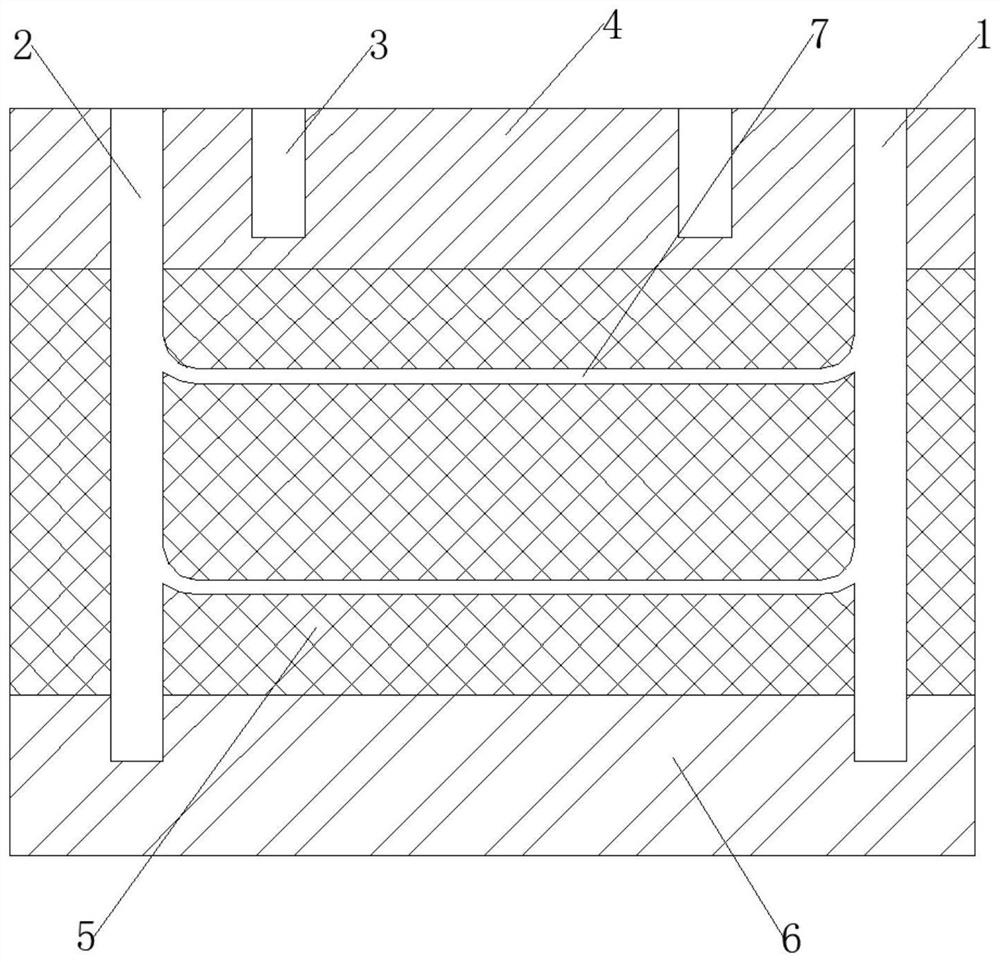

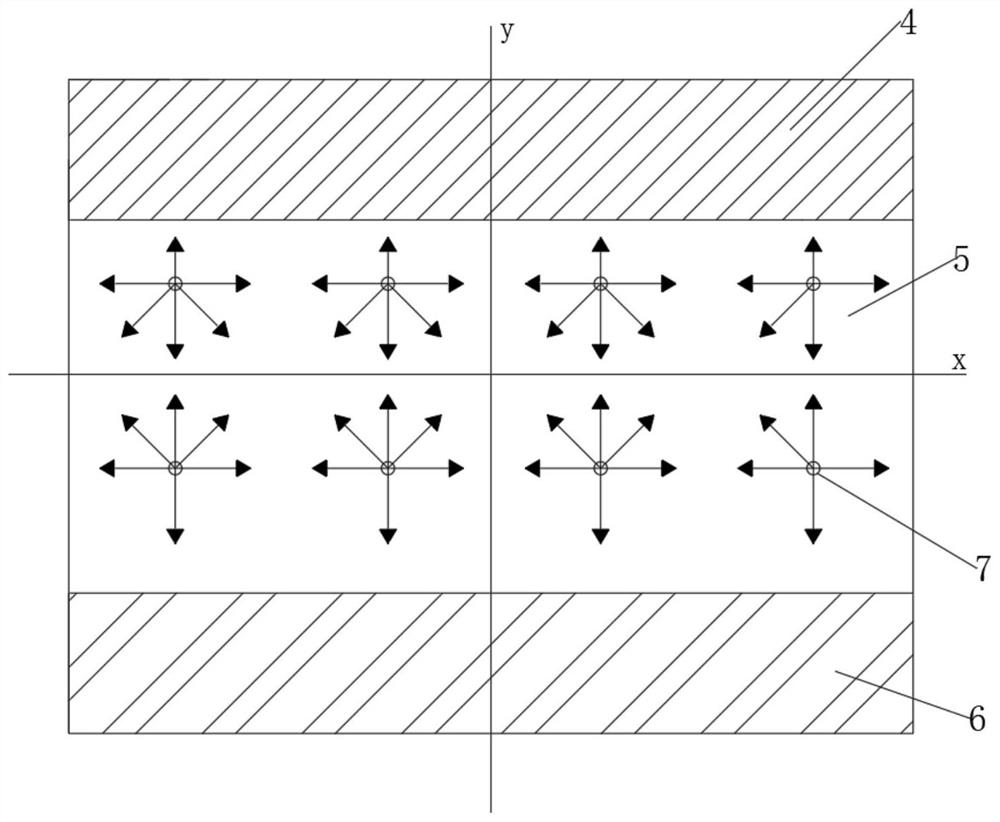

[0039] Step two, as figure 2 As shown, an injection well 1 and a production well 2 are drilled in each oil-rich coal block, and the injection well 1 and the production well 2 are drilled below the coal seam floor 6. Specifically, the above-mentioned injection well 1 and production well 2 Drilling to 5 meters below the coal seam floor 6, the injection well 1 and the production well 2 are cemented in the whole well section, and temperature sensors are provided on the outside of the casing of the injection well 1 and the production well 2, and the temperature sensors are respectively located on the upper part of the coal seam roof 4 2 meters, the middle of the coal seam 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com