Production method of PA56/PA6 bio-based splendor stripe composite elastic nylon yarn

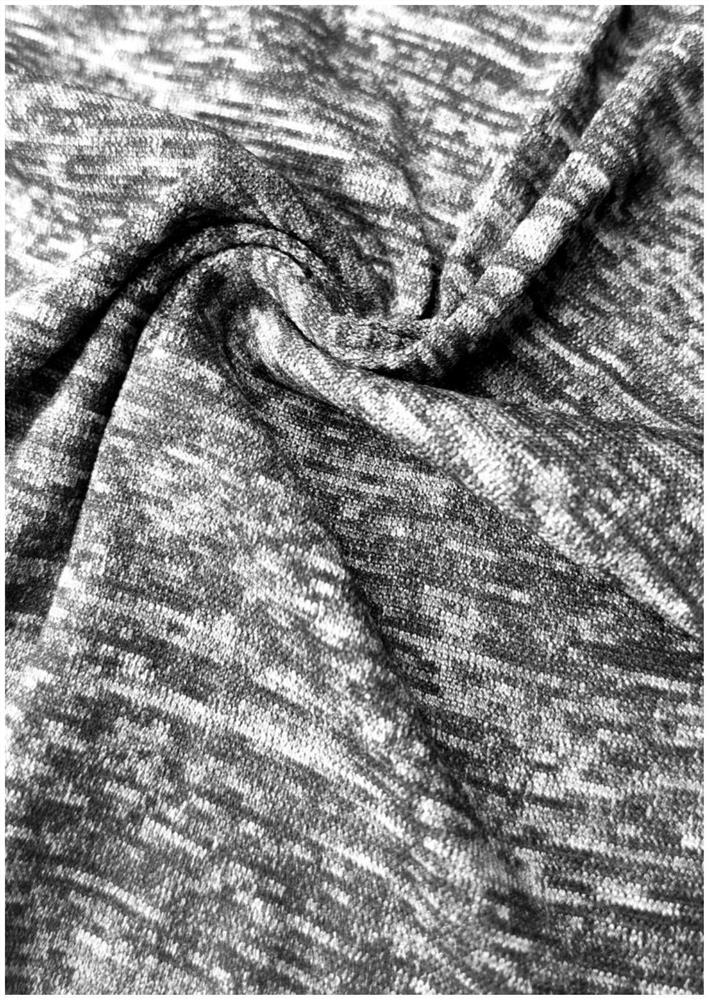

A production method, bio-based technology, applied in textile/flexible product manufacturing, melt spinning, final product manufacturing, etc., which can solve the problems of spinnability and dyeing effect discount, unstable production of deep dyed chips, blurred dyeing stripes, etc. , to achieve the effect of good wear resistance, high strength and easy dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

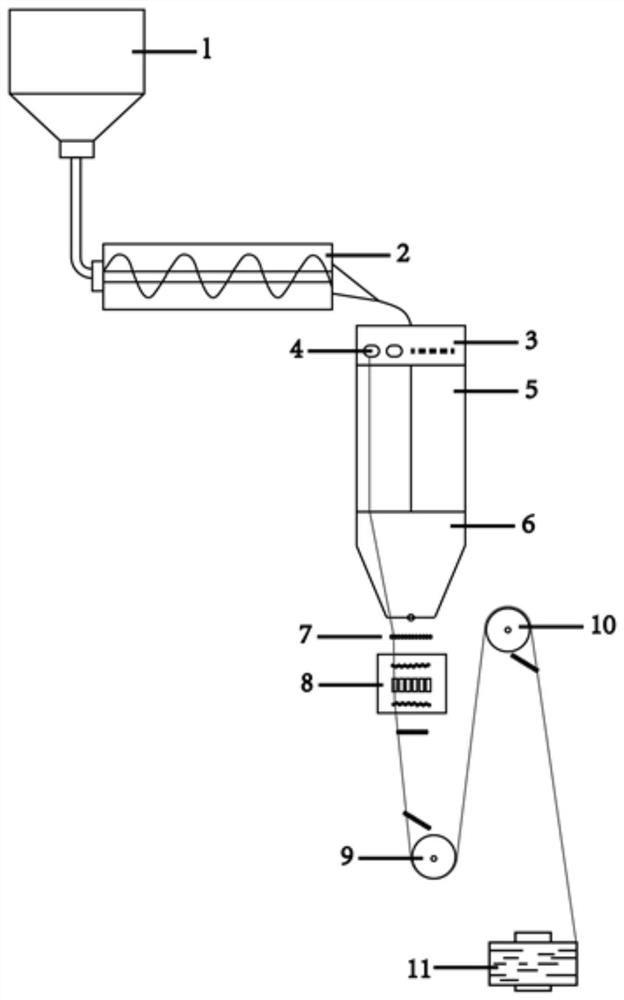

[0037] 1. Two kinds of POY raw materials are prepared by melt spinning (for the specific process, see figure 1 shown):

[0038] 1. Preparation of POY1:PA56:

[0039] Production raw materials: Kasai biological PA56 deep-dyed semi-gloss slices

[0040] Operating procedure:

[0041] (1) Put the dried semi-extinct PA56 slices into the silo, melt through the screw extruder, accurately measure and distribute by the metering pump, and then enter the spinning box and spin through the component spinneret; the screw extrudes The temperature of each zone of the machine is controlled between: 270-280°C (five zones: 270°C, 275°C, 278°C, 278°C, 280°C); the melting temperature of the melt is controlled at 275°C; the component pressure is controlled at 17MPa.

[0042](2) Cooling by side blowing, the oil nozzle is concentrated on oil; the wind speed of side blowing is 0.38m / s, the air temperature is 17.5℃, and the wind humidity: 90%; the blowing direction of side blowing is perpendicular to...

Embodiment 2

[0062] 1. Two kinds of POY raw materials are prepared by melt spinning (for the specific process, see figure 1 shown):

[0063] 1. Preparation of POY1:PA56:

[0064] Production raw materials: Kasai biological PA56 deep-dyed semi-gloss slices

[0065] Operating procedure:

[0066] (1) Put the dried semi-extinction PA6 slices into the silo, melt through the screw extruder, accurately measure and distribute by the metering pump, and then enter the spinning box and spin through the component spinneret; the screw extrudes The temperature of each zone of the machine is controlled between: 270-280°C (five zones: 270°C, 275°C, 278°C, 278°C, 280°C); the melting temperature of the melt is controlled at 270°C; the component pressure is controlled at 18MPa.

[0067] (2) The side blower is cooled, and the oil nozzles are oiled and concentrated; the wind speed of the side blower is 0.55m / s, the wind temperature is 18.5℃, and the wind humidity: 95%; the blowing direction of the side blowe...

Embodiment 3

[0087] 1. Two kinds of POY raw materials are prepared by melt spinning (for the specific process, see figure 1 shown):

[0088] 1. Preparation of POY1:PA56:

[0089] Production raw materials: Kasai biological PA56 deep-dyed semi-gloss slices

[0090] Operating procedure:

[0091] (1) Put the dried semi-extinct PA56 slices into the silo, melt through the screw extruder, accurately measure and distribute by the metering pump, and then enter the spinning box and spin through the component spinneret; the screw extrudes The temperature of each zone of the machine is controlled between 270-280°C (five zones: 270°C, 275°C, 278°C, 278°C, 280°C); the melting temperature of the melt is controlled at 279°C; the component pressure is controlled at 17MPa.

[0092] (2) The side blower is cooled, and the oil nozzles are oiled and clustered; the wind speed of the side blower is 0.45m / s, the wind temperature is 18°C, and the wind humidity: 92%; the blowing direction of the side blower is pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com