Water-based adhesive for bonding rubber and metal and preparation method of water-based adhesive

A metal bonding and adhesive technology, applied in the direction of adhesives, adhesive types, asphalt material adhesives, etc., can solve the problems of slow curing speed, poor self-adhesiveness and mutual adhesion of adhesives, low bonding strength, etc., to achieve strong The effect of bonding speed and strength, fast curing speed, and large bonded area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

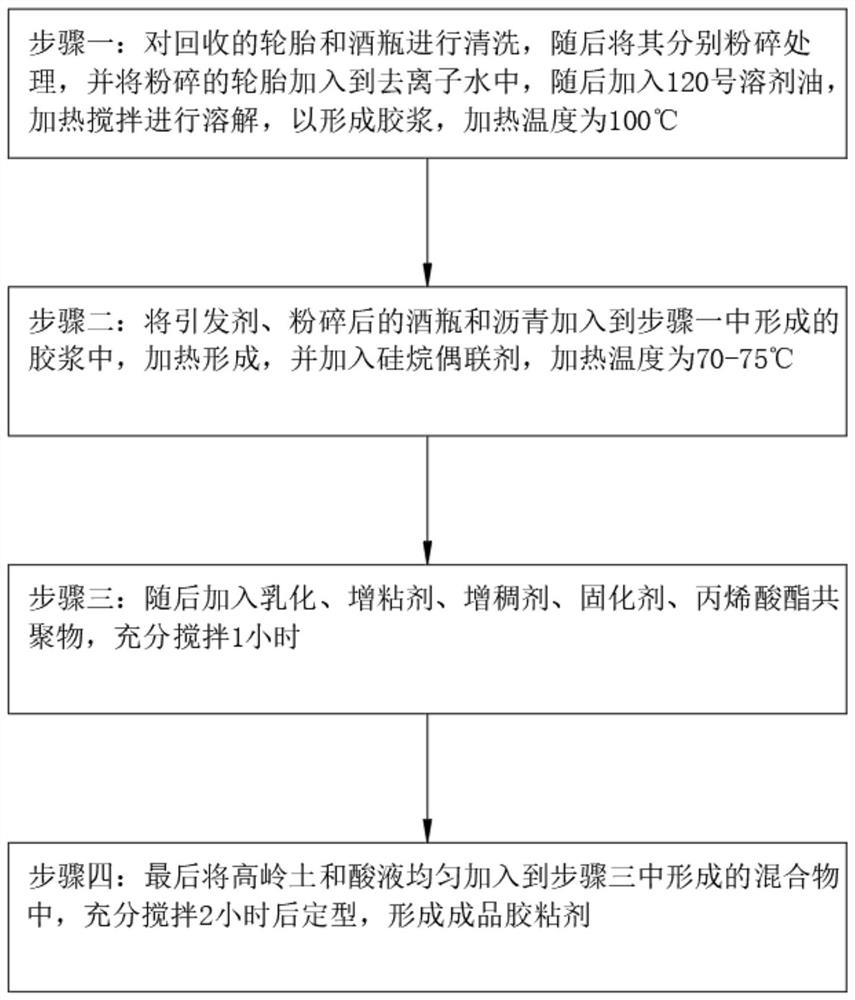

Image

Examples

Embodiment 1

[0024] A water -based adhesive for rubber and metal bonding, including 22.5 copies of ionic water, 9 copies of polystyrene, 6 parts of glass, 6 copies of emulsifiers, 6 citations, 6 adhesives, 6 thickened agents , 4 parts of curing agent, 10 pieces of asphalt, 2.5 copies of acrylic symbol, 5.5 parts of coupling agents, and 8 parts of kaolin.

[0025] Preferably, the puppet couplet is a sibidine coupling agent, polystyrene and glass are recycled old tires and old wine bottles.

[0026] Preferably, the main components of acrylate clusters are acrylic, acrylic isessy, methyl acrylic, and acrylic hydroxyl ester.

[0027] Preferably, the silane coupling agent is γ-oblite-oxyl ether propyl tritenol, γ-ethylene triaxyxyne silane, γ-amino oxyxane, and ethylene three uncle, Base-based oxide, γ- (methyl acrylic acid) propyl tritenols, γ-mesopropyl oxide, or phenyl oxygenosililane.

[0028] Preferably, the emulsifier is an anterogenesis emulsifier, which is specifically for sodium sodium sod...

Embodiment 2

[0032] A water -based adhesive for rubber and metal bonding, including 22.5 copies of ionic water, 9 copies of polystyrene, 6 parts of glass, 6 copies of emulsifiers, 6 citations, 6 adhesives, 6 thickened agents , 4 copies of curing agents, 10 pieces of asphalt, 2.5 copies of acrylate symbols, 5.5 parts of coupling agents, 8 parts of kaolin, and 5 chloride solutions.

[0033] Preferably, the puppet couplet is a sibidine coupling agent, polystyrene and glass are recycled old tires and old wine bottles.

[0034] Preferably, the main components of acrylate clusters are acrylic, acrylic isessy, methyl acrylic, and acrylic hydroxyl ester.

[0035] Preferably, the silane coupling agent is γ-oblite-oxyl ether propyl tritenol, γ-ethylene triaxyxyne silane, γ-amino oxyxane, and ethylene three uncle, Base-based oxide, γ- (methyl acrylic acid) propyl tritenols, γ-mesopropyl oxide, or phenyl oxygenosililane.

[0036] Preferably, the emulsifier is an anterogenesis emulsifier, which is specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com