Production method and application of biodegradable lignocellulose bioplastic

A production method and technology of bioplastics, applied in the field of production and application of biodegradable lignocellulose bioplastics, can solve problems such as waste of resources, and achieve the effects of uniform dispersion, environmentally friendly and efficient methods, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

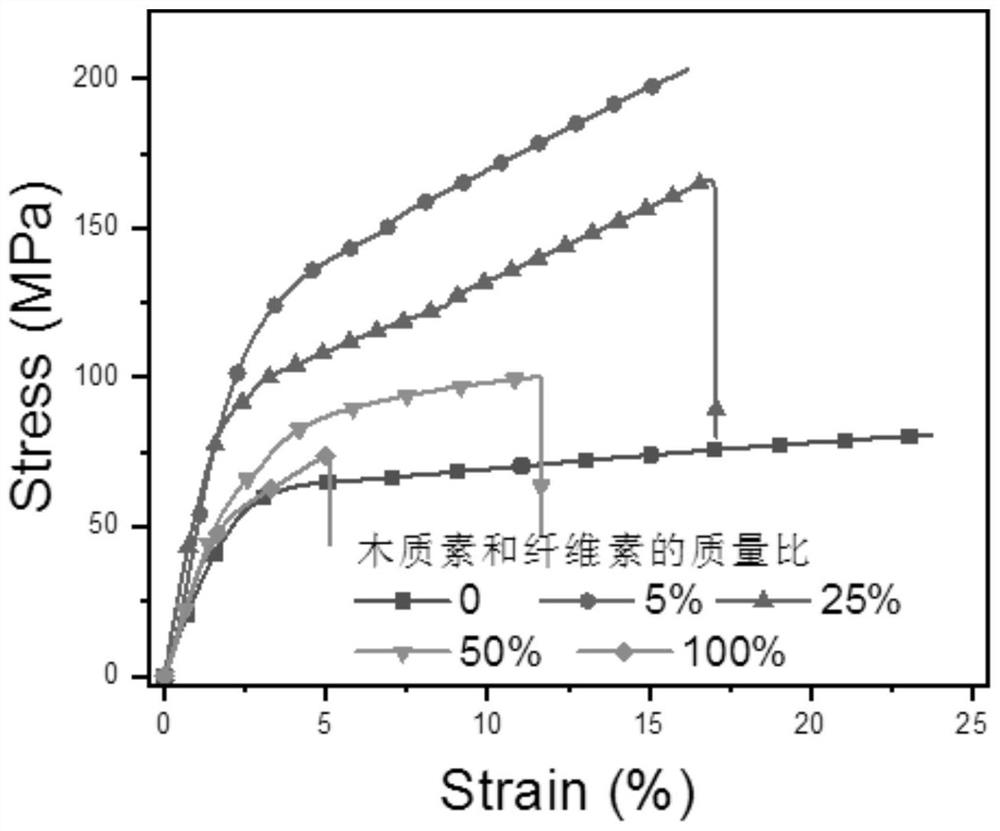

[0032] 7wt% NaOH, 12wt% urea and balance water were prepared into a solvent, pre-cooled to below freezing point, adding cotton linter pulp with a polymerization degree of 500, and stirring to obtain a cellulose solution with a concentration of 4wt%. The calcium lignosulfonate powder is directly added to the above solution, and stirred at below 5° C. until completely dissolved to obtain a lignin / cellulose composite solution. The solution was formed into a film by a casting method and then placed in a 5 wt % acetic acid aqueous solution, and washed to obtain a lignin / cellulose composite hydrogel film. The hydrogel was dried by roll-to-roll hot pressing to obtain a lignin / cellulose composite bioplastic film.

Embodiment 2

[0034] 7wt% NaOH, 12wt% urea and balance water are prepared into a solvent, pre-cooled to below freezing point, wood pulp with a polymerization degree of 600 is added, and a 4wt% cellulose solution is obtained by stirring. The alkaline lignin powder was directly added to the above solution and stirred at 5° C. until completely dissolved to obtain a lignin / cellulose composite solution. The chemical cross-linking agent epichlorohydrin of the same quality as the lignin was slowly added dropwise to the above solution and stirred evenly. Cellulose composite hydrogel membrane. The hydrogel was dried by roll-to-roll hot pressing to obtain a lignin / cellulose composite bioplastic film.

Embodiment 3

[0036] 7wt% NaOH, 12wt% urea and remaining water were prepared into a solvent, pre-cooled to below freezing point, added cotton linter pulp with a degree of polymerization of 500, and stirred vigorously to obtain a cellulose solution with a concentration of 4wt%. The alkaline lignin powder was directly added to the above solution and stirred at 5° C. until completely dissolved to obtain a lignin / cellulose composite solution. A certain amount of cross-linking agent ethylene glycol diglycidyl ether was added and stirred evenly, and after film-forming by casting method, it was immersed in a 5wt% phosphoric acid aqueous solution, and washed to obtain a lignin / cellulose composite hydrogel film. The hydrogel was dried by plate hot pressing to obtain a lignin / cellulose bioplastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com