High-transparency thermosensitive recording material and preparation method thereof

A heat-sensitive recording material, heat-sensitive technology, applied in the direction of temperature recording method, copy/marking method, printing, etc., can solve the problems of low haze, high transparency, etc., achieve low haze, anti-oil and anti-plasticizer Excellent performance and uniform printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

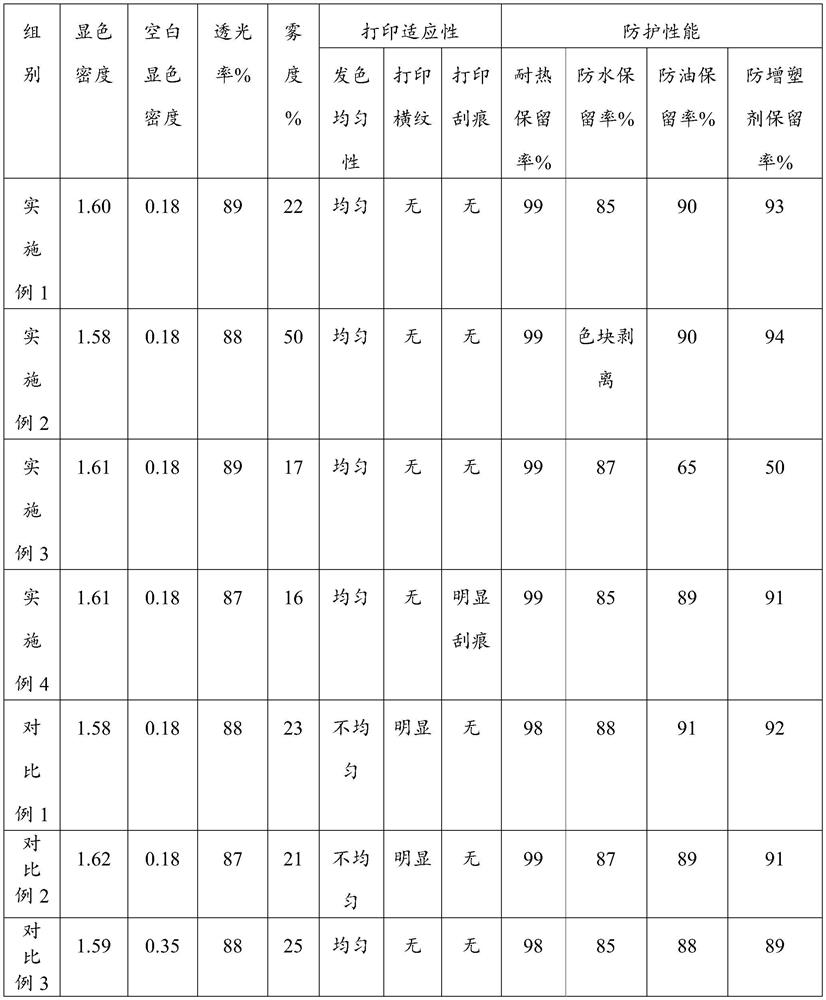

Examples

Embodiment 1

[0033] The present embodiment provides a thermosensitive recording material, which sequentially includes a substrate, a coating layer, a thermosensitive color-developing layer and a protective layer; the preparation method of the thermosensitive recording material comprises the following steps:

[0034] 1. Then the coating solution (by weight fraction) is: 27 parts of Diaisheng VONCOAT AC-501 acrylic emulsion (glass transition temperature Tg=0°C), BASF Joncryl 67 styrene-acrylic emulsion (Tg=73°C) 58 parts, 0.75 part of phosphate ester wetting agent, 5 parts of cellulose rheology modifier, 4 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, Xia 4.25 servings of stone powder. Using water as a solvent, the above components are stirred and mixed, and the solid content is controlled to be 5% to prepare a coating solution for subsequent coating.

[0035] 2. The coating solution of the heat-sensitive color developing layer (by weight fraction) is: 1.5 parts of D...

Embodiment 2

[0039] This embodiment provides a thermosensitive recording material. Compared with Embodiment 1, this embodiment is only different in the coating solution of the thermosensitive color developing layer.

[0040] In this example, the coating solution of the heat-sensitive color developing layer (in parts by weight) is: 35 parts of modified PVA RS-1717, 2 parts of polyethylene wax (Tg=140°C, D90<1.0μm), glyoxal 5 parts, 2-anilino-3-methyl-6-dibutylaminofluoran (D90<0.5μm) 15 parts, 2,4-dihydroxydiphenylsulfone (D90<0.5μm) 30.75 parts, 4-hydroxyl -10 parts of 3-allyl diphenyl sulfone (D90<0.5 μm), 1.25 parts of phosphate ester wetting agent. Using water as a solvent, the above components are stirred and mixed, and the solid content is controlled to be 10% to prepare a coating solution for a heat-sensitive color developing layer.

Embodiment 3

[0042] This embodiment provides a thermosensitive recording material. Compared with Embodiment 1, this embodiment is only different in the coating solution of the thermosensitive color developing layer.

[0043] In this example, the coating solution (in parts by weight) of the heat-sensitive color developing layer is: 1.5 parts of Diaisheng VONCOAT AC-501 acrylic emulsion (Tg=0°C), BASF Joncryl 67 styrene-acrylic emulsion (Tg=73°C) ) 13.5 parts, modified PVA RS-171720 parts, polyethylene wax (Tg=140℃, D90<1.0μm) 2 parts, glyoxal 5 parts, 2-anilino-3-methyl-6-dibutylamino 15 parts of fluoran (D90<0.5 μm), 40.75 parts of 4-hydroxy 3-allyldiphenyl sulfone (D90<0.5 μm), and 1.25 parts of phosphate ester wetting agent. Using water as a solvent, the above components are stirred and mixed, and the solid content is controlled to be 10% to prepare a coating solution for a heat-sensitive color developing layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com