Composition for clearing liver and nourishing lung and processing method thereof

A composition and liver-clearing technology, applied in the directions of drug combination, non-active components of polymer compounds, pharmaceutical formulations, etc., can solve problems such as aggravating liver burden, and achieve the effect of promoting absorption, improving solubility and bioavailability, and high enzymatic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

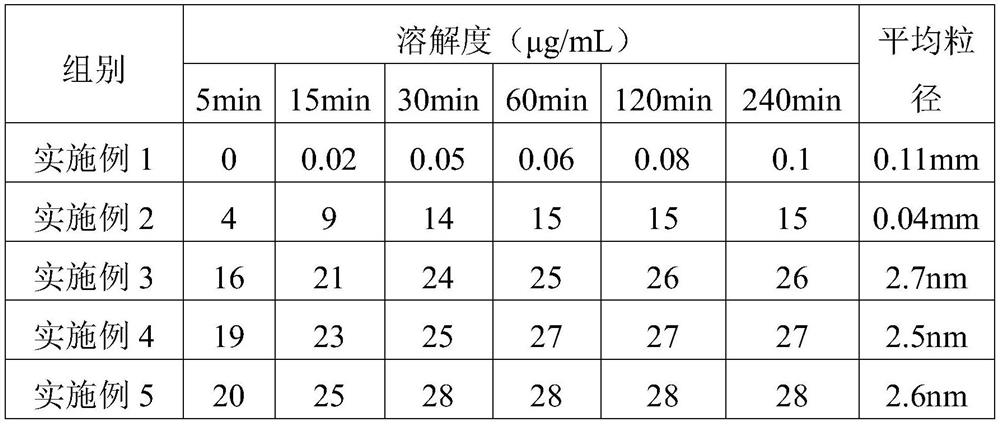

Embodiment 1

[0060] A composition for clearing liver and nourishing lung, its processing method comprises the following steps:

[0061] (1) Weigh each raw and auxiliary material;

[0062] (2) Mix and heat 20g trehalose, 5g erythritol, 0.001g mogroside, 150g water and 120g glycerol to 75°C, add 300g gelatin and stir until completely dissolved, then add titanium dioxide and caramel-colored suspension and stir 15min, vacuumed to -0.06MPa, passed through a 100-mesh sieve, and kept at 60°C to obtain rubber;

[0063] (3) 35g mono-, diglyceride fatty acid esters and 200g silymarin seed oil are heated to 55 ℃ to dissolve, after cooling to 35 ℃, add 30g naringin extract, 120g loquat leaf extract, 5g loquat powder, 30g orange red The powder, 7g of phospholipids and 273g of silymarin seed oil were mixed and stirred for 20min, passed through a colloid mill twice, and passed through an 80-mesh sieve to obtain the content material;

[0064] (4) pressing the rubber skin obtained in step (2) and the con...

Embodiment 2

[0070] A composition for clearing liver and nourishing lung, its processing method comprises the following steps:

[0071] (1) Weigh each raw and auxiliary material;

[0072] (2) Mix and heat 20g trehalose, 5g erythritol, 0.001g mogroside, 150g water and 120g glycerin to 75°C, add 300g gelatin and stir until completely dissolved, then add titanium dioxide and caramel-colored suspension and stir 15min, vacuumed to -0.06MPa, passed through a 100-mesh sieve, and kept at 60°C to obtain rubber;

[0073] (3) 35g mono-, diglyceride fatty acid esters and 200g silymarin seed oil were heated to 55°C to dissolve, and after cooling to 35°C, 30g of α-glycosylated naringin extract, 120g of loquat leaf extract, 5g of loquat were added Powder, 30g orange powder, 7g phospholipid and 273g milk thistle seed oil were mixed and stirred for 20min, passed through a colloid mill twice, and passed through an 80-mesh sieve to obtain the content material;

[0074] (4) pressing the rubber skin obtained...

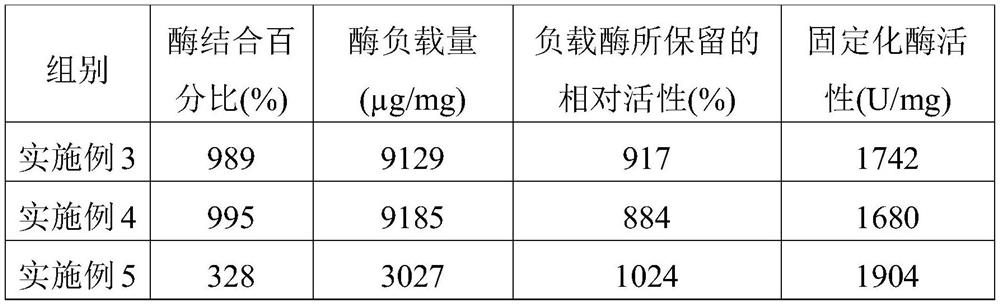

Embodiment 3

[0081] A composition for clearing liver and nourishing lung, its processing method comprises the following steps:

[0082] (1) Weigh each raw and auxiliary material;

[0083] (2) Mix and heat 20g trehalose, 5g erythritol, 0.001g mogroside, 150g water and 120g glycerin to 75°C, add 300g gelatin and stir until completely dissolved, then add titanium dioxide and caramel-colored suspension and stir 15min, vacuumed to -0.06MPa, passed through a 100-mesh sieve, and kept at 60°C to obtain rubber;

[0084] (3) 35g mono-, diglyceride fatty acid esters and 200g silymarin seed oil were heated to 55°C to dissolve, and after cooling to 35°C, 30g of α-glycosylated naringin extract, 120g of loquat leaf extract, 5g of loquat were added Powder, 30g orange powder, 7g phospholipid and 273g milk thistle seed oil were mixed and stirred for 20min, passed through a colloid mill twice, and passed through an 80-mesh sieve to obtain the content material;

[0085] (4) pressing the rubber skin obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com