Cobalt-based multifunctional catalyst simulating branch and leaf structure of pinus thunbergii and preparation method of cobalt-based multifunctional catalyst

A pine branch and leaf, multifunctional technology is applied in the field of cobalt-based multifunctional catalyst with imitation black pine branch and leaf structure and its preparation field, which can solve the problems of reduced activity, reduced catalytic activity and catalytic efficiency, and achieves high porosity and avoids catalytic activity. The effect of reducing, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

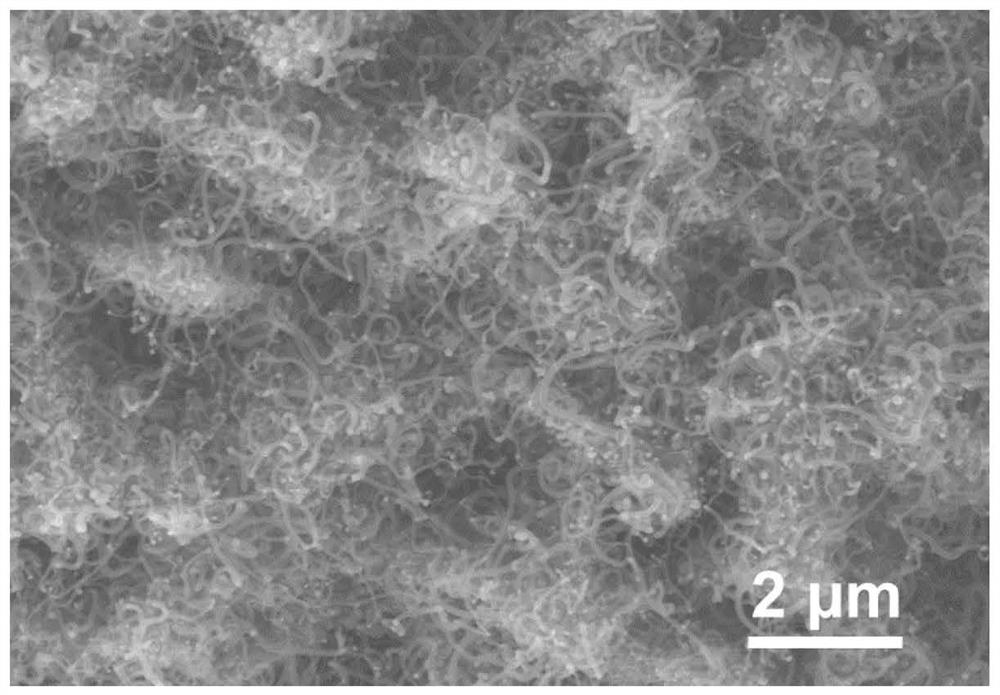

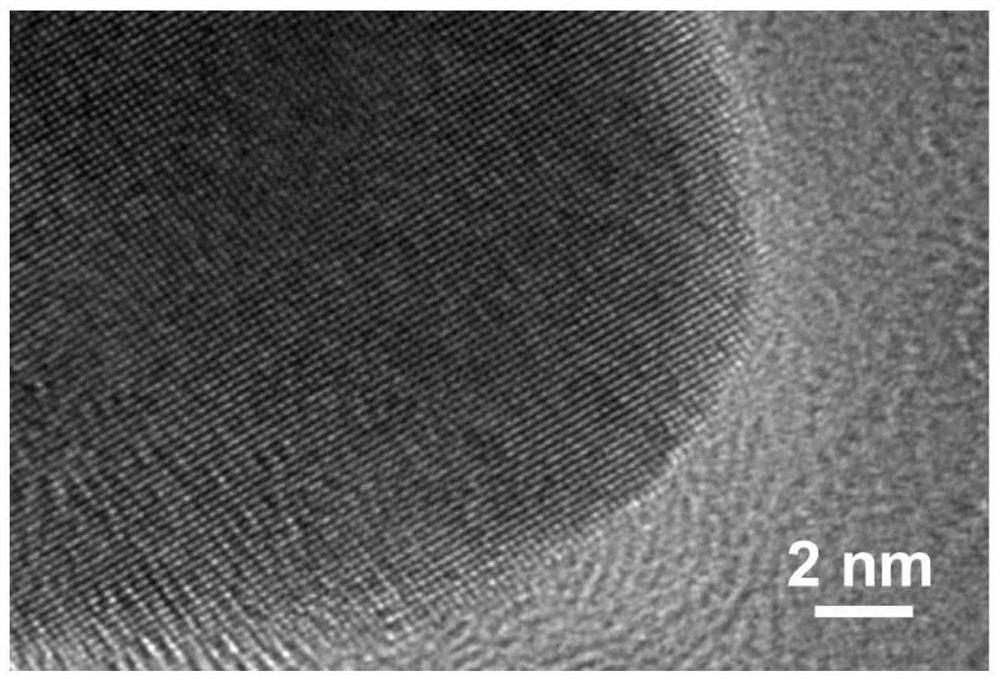

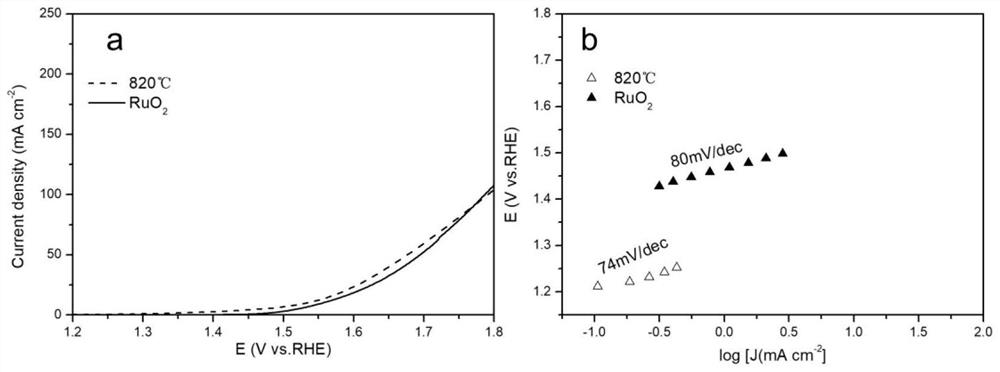

[0037] The present embodiment provides a cobalt-based multifunctional catalyst imitating black pine branch and leaf structure, which is obtained by the following method, and the details are as follows:

[0038] Step A: Mix and stir 6 mL of ethanol and 6 g of melamine to form a melamine slurry of 1 g / mL, stir with a magnetic stirrer, place the slurry in a graphite boat after mixing evenly, and dry it for later use; wherein, the drying temperature is 50℃, drying time is 2h;

[0039] Step B: Cut the carbon paper into a size of 1cm×0.8cm, then ultrasonically clean it with acetone, ethanol and deionized water for 20 minutes, and put it into a vacuum drying box for drying; the carbon paper after drying is etched by plasma, and the work The frequency is 13MHz, the etching time is 5min, and the treated carbon paper is placed in a glove box in an argon atmosphere for later use;

[0040]Step C: Dissolve 600 mg of cobalt nitrate hexahydrate and 1.4 g of dimethylimidazole in 25 mL of dei...

Embodiment 2

[0050] The present embodiment provides a cobalt-based multifunctional catalyst imitating black pine branch and leaf structure, which is obtained by the following method, and the details are as follows:

[0051] Step A: Mix and stir 8 mL of ethanol and 8 g of melamine to form a melamine slurry of 1 g / mL, stir with a magnetic stirrer, place the slurry in a graphite boat after mixing evenly, and dry it for later use; wherein, the drying temperature is: 80℃, drying time is 4h;

[0052] Step B: Cut the carbon paper into a size of 1cm×0.8cm, then ultrasonically clean it with acetone, ethanol and deionized water for 20 minutes, and put it into a vacuum drying box for drying; the carbon paper after drying is etched by plasma, and the work The frequency is 12.8MHz, the etching time is 8min, and the treated carbon paper is placed in a glove box in an argon atmosphere for later use;

[0053] Step C: Dissolve 800 mg of cobalt nitrate hexahydrate and 1.8 g of dimethylimidazole in 25 mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com