Polyimide-coated lithium ion battery positive electrode active material, preparation method and application

A positive electrode active material and lithium-ion battery technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of concentrated thermal effect inside the battery, crushing and cracking of active materials, and unfavorable industrial production, so as to increase the bonding effect and maintain Stability, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

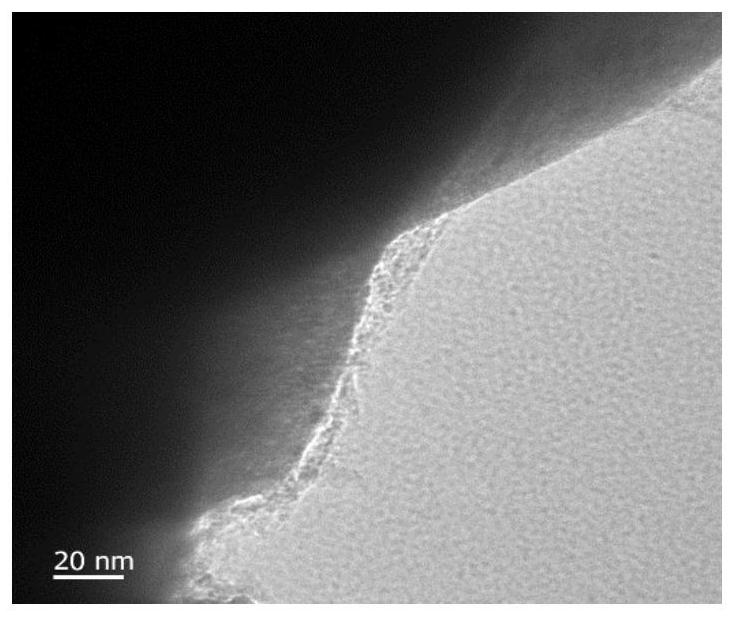

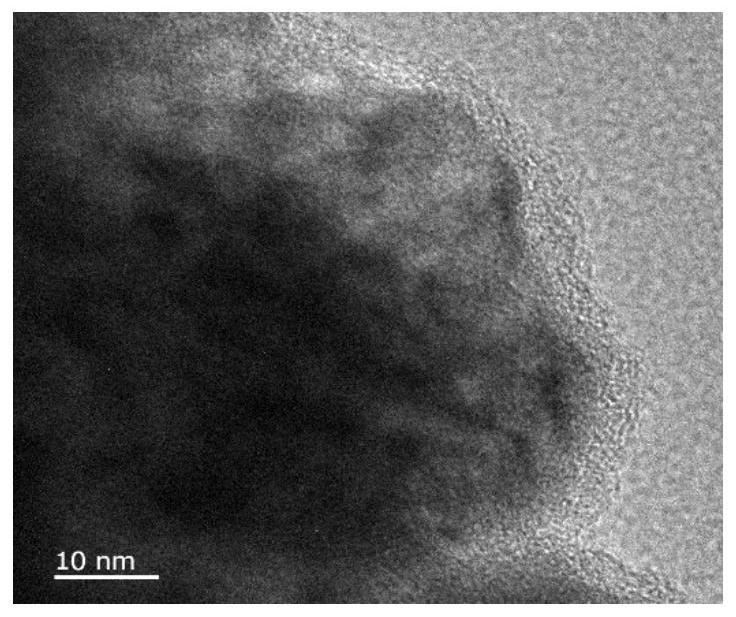

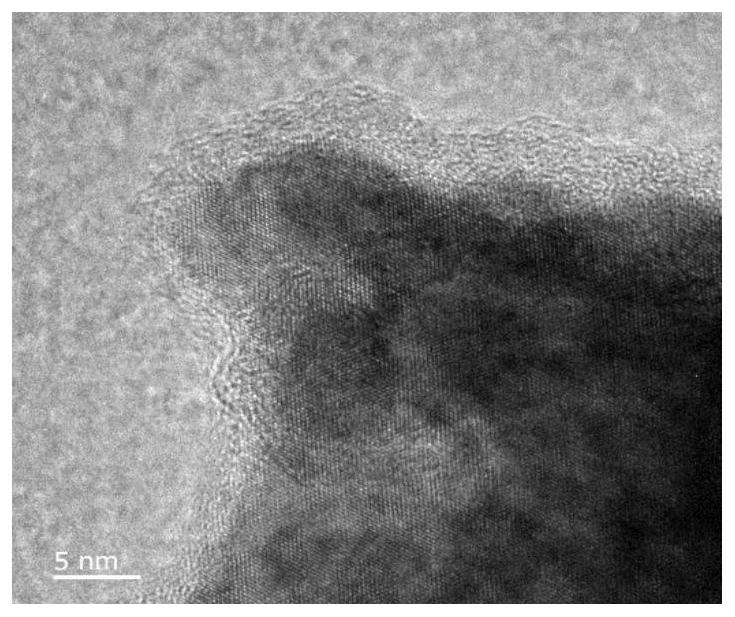

Image

Examples

Embodiment 1

[0044] Weigh out 6FDA 6.57g, ODA 1.47g, and TFDB 2.35g with a molar ratio of 10:5:5. Dissolve ODA and TFDB in 30ml of NMP solvent, stir mechanically, after ODA and TFDB are all dissolved in NMP, under ice-water bath conditions, add 6FDA to obtain a polyamic acid solution with a solid content of 25%. Dilute to a 10% solids solution. The positive active material lithium iron phosphate is placed in the above-mentioned 10% polyamic acid solution, mixed, centrifuged, suction filtered, and dried to prepare the positive active material coated with polyamic acid. For amination treatment, the heat treatment process is to heat up from room temperature to 300°C at a constant rate for 60min, and keep the temperature for 60min. Mix the surface-coated lithium iron phosphate, conductive carbon black, and PVDF solutions according to 80%, 10%, and 10% by mass, add NMP solvent to dissolve the mixture, and stir for 20 minutes to prepare a positive electrode slurry. The positive electrode slurr...

Embodiment 2

[0047] Weigh 6FDA 6.57g, ODA 1.47g, and TFDB 2.35g with a molar ratio of 10:5:5, dissolve all ODA and TFDB in 30ml of NMP solvent, stir mechanically, and after ODA and TFDB are all dissolved in NMP, take an ice-water bath Under the condition of , 6FDA is added step by step to obtain a polyamic acid solution with a solid content of 25%, and the polyamic acid solution is prepared into a solution with a solid content of 5%. The positive electrode active material lithium iron phosphate was placed in a 5% polyamic acid solution, mixed, centrifuged, filtered, and dried to prepare a polyamic acid-coated positive electrode active material. After grinding and sieving, high temperature thermal imide Chemical treatment, the heat treatment process is from room temperature to 300 °C for 60 min at a constant rate, and heat preservation for 60 min. Mix the surface-coated lithium iron phosphate, conductive carbon black, and PVDF solutions according to 80%, 10%, and 10% by mass, add NMP solven...

Embodiment 3

[0050] Weigh 6FDA 6.57g, ODA 1.47g, and TFDB 2.35g with a molar ratio of 10:5:5, dissolve all ODA and TFDB in 30ml of NMP solvent, stir mechanically, and after ODA and TFDB are all dissolved in NMP, take an ice-water bath Under the condition of , 6FDA is added step by step to obtain a polyamic acid solution with a solid content of 25%, and the polyamic acid solution is prepared into a solution with a solid content of 5%. The positive active material NCM523 was placed in a 5% polyamic acid solution, mixed, centrifuged, filtered, and dried to prepare a polyamic acid-coated positive active material. After grinding and sieving, high-temperature thermal imidization was performed. , the heat treatment process is to heat up from room temperature to 300°C at a constant rate for 60min, keep for 60min, mix conductive carbon black and PVDF solution according to the mass fraction of 80%, 10% and 10%, and add NMP solvent. The surface-coated NCM523 was dissolved in the mixture and stirred f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com