Multi-stage frequency ultrasonic vibration pulsating heat pipe device and operation process thereof

A pulsating heat pipe and ultrasonic vibration technology, applied in heat transfer modification, indirect heat exchanger, heat exchange equipment, etc., can solve problems such as affecting the accuracy of temperature measurement and cannot be used under ultrasonic conditions, and achieve the true frequency and amplitude Controllable, simple structure, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

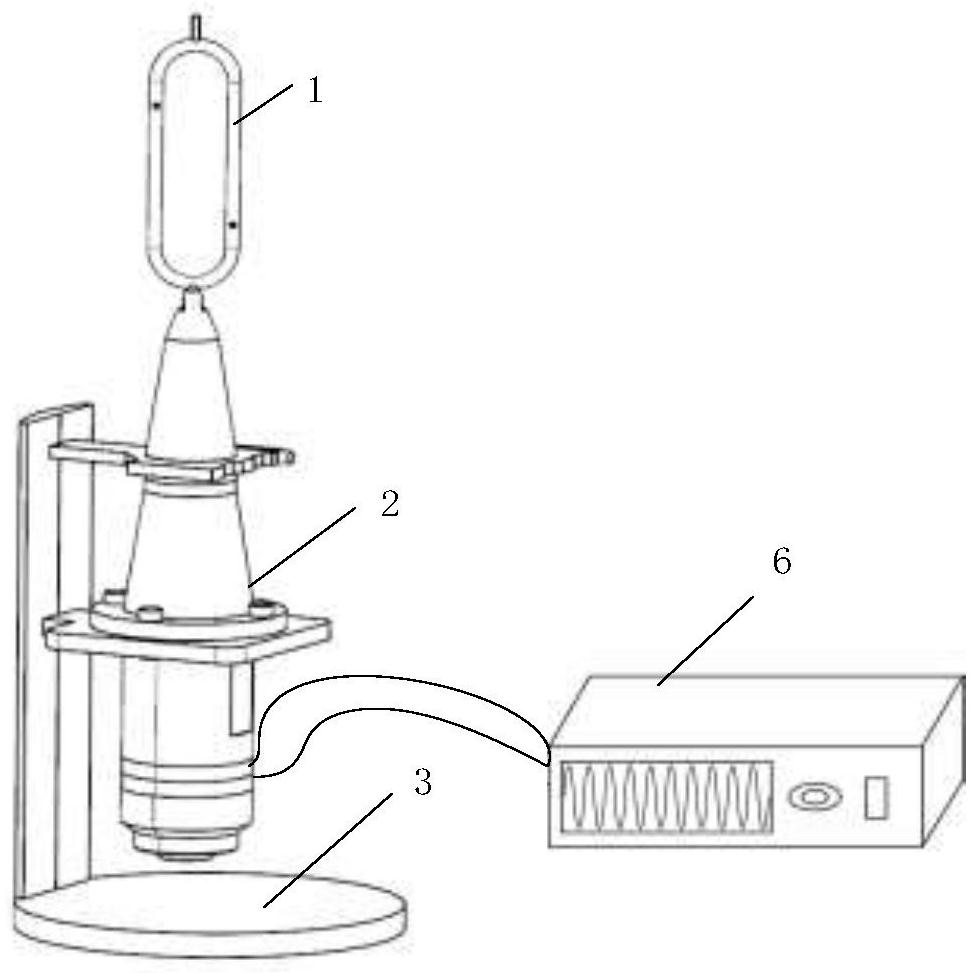

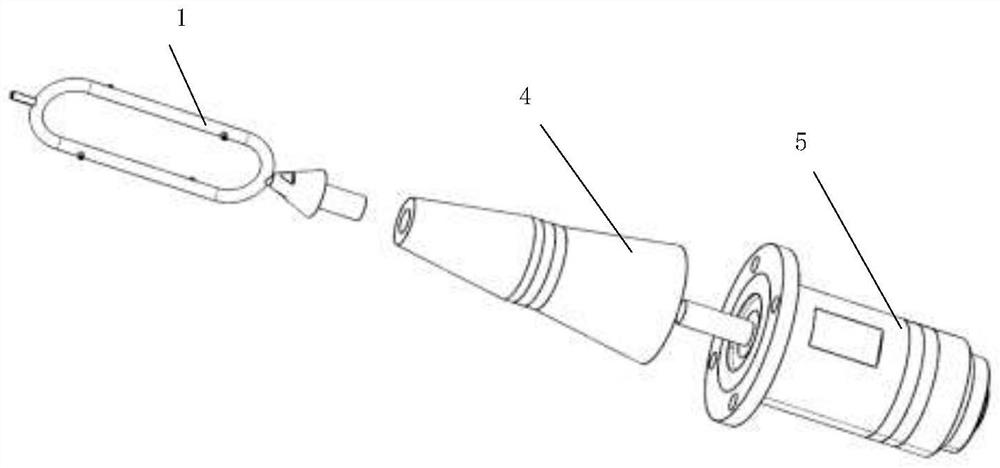

[0044] figure 1 It is a schematic diagram of the overall structure of the multi-stage frequency ultrasonic vibration pulsating heat pipe device according to the present invention, figure 2 It is an exploded diagram of the structure. refer to figure 1 , 2 As shown, a multi-stage frequency ultrasonic vibration pulsating heat pipe device includes a pulsating heat pipe 1 , a secondary ultrasonic vibrator 2 , a support frame 3 and an ultrasonic power source 6 in order from top to bottom. The secondary ultrasonic vibrator includes a primary ultrasonic vibrator 4 and an ultrasonic assembly 5, which are fixed on the support frame by means of a flange arranged at a half-wavelength node position, and the ultrasonic power source can be connected to the primary ultrasonic vibrator 4 or the secondary ultrasonic vibrator 2. Select the operating frequency.

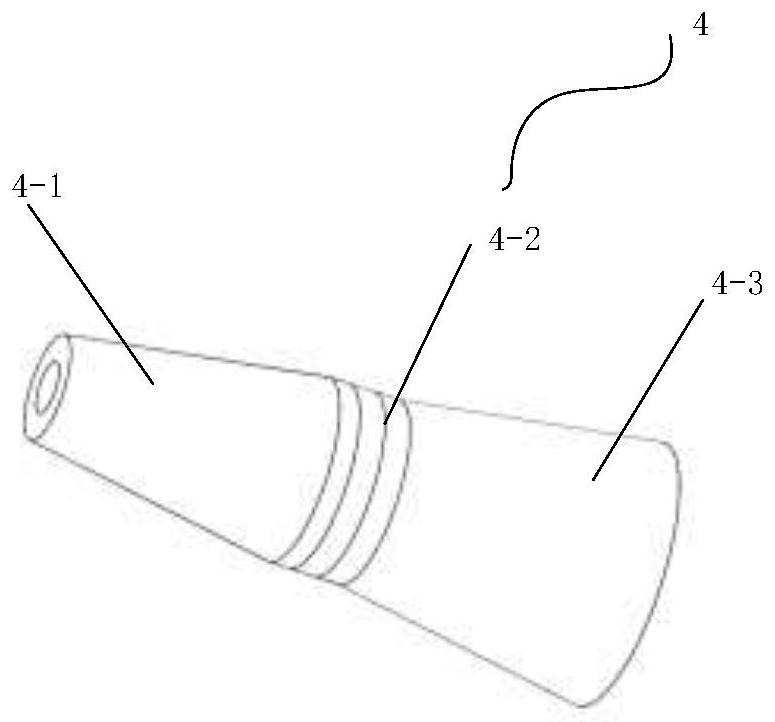

[0045] image 3 is a schematic diagram of the structure of the first-stage ultrasonic vibrator 4, Figure 4 for image 3 Schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com