Preparation method and application of controllable degradation tissue reconstruction and repair material

A technology for repairing materials and tissues, applied in the field of controllable degradation of biomedical materials, can solve problems such as poor shape, difficulty in maintaining three-dimensional space, and inability to meet clinical needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

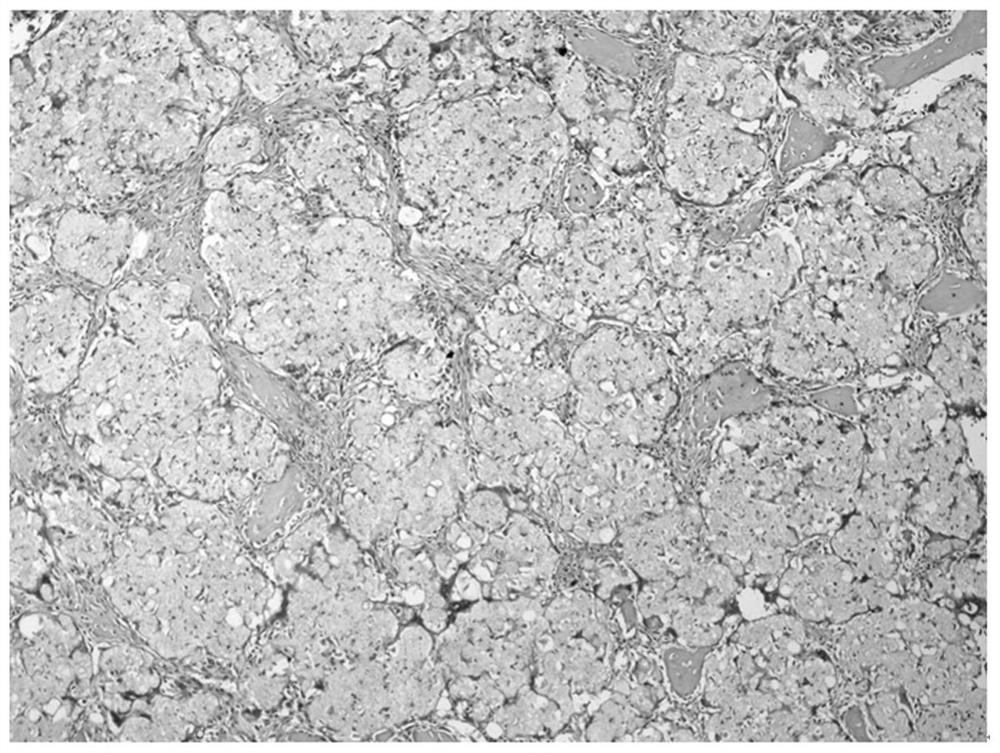

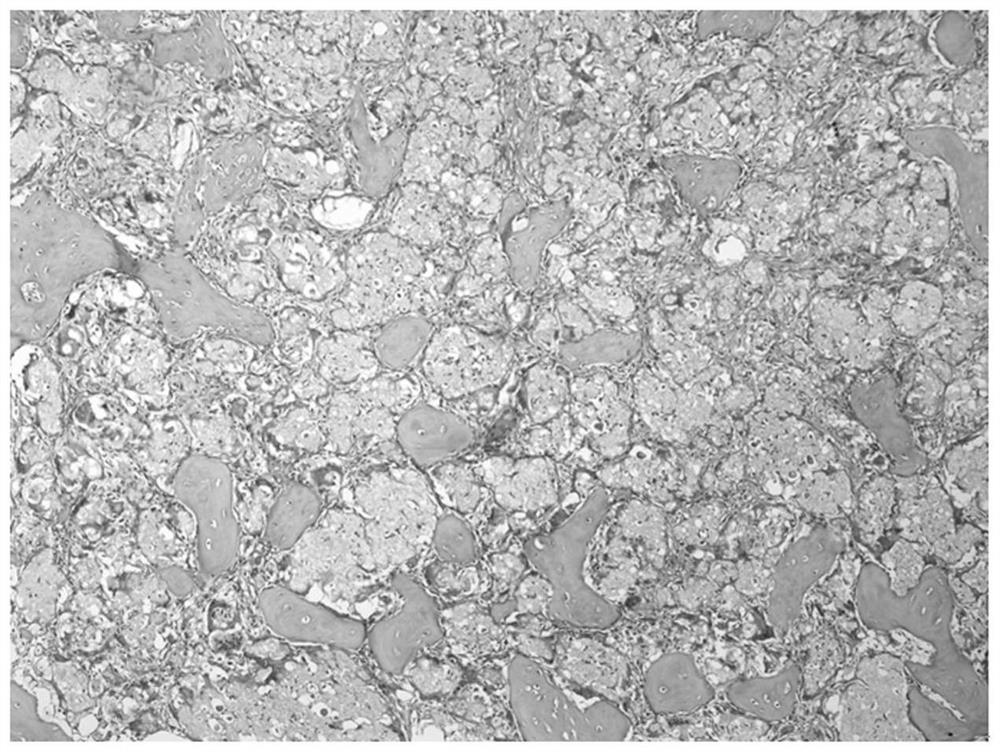

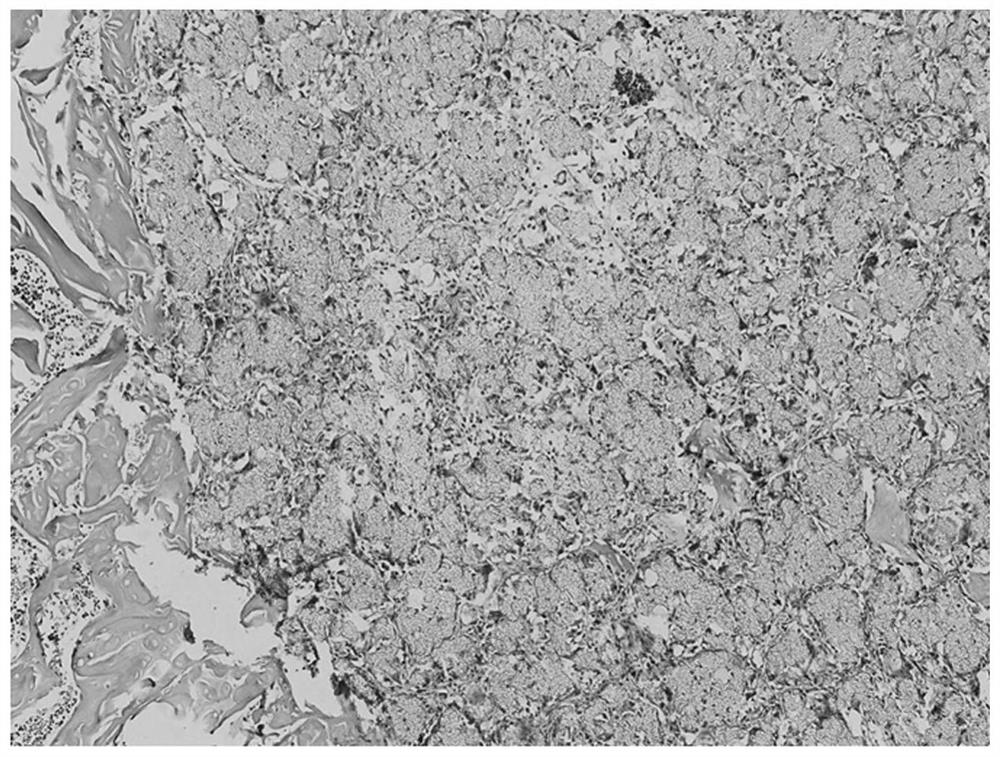

Image

Examples

preparation example Construction

[0022] The present application provides a method for preparing a controllable degradable tissue reconstruction and repair material, comprising the following steps:

[0023] Step 1: Dissolving hydroxyapatite (HA) in water to obtain a hydroxyapatite suspension.

[0024] In the above steps, the concentration of the hydroxyapatite suspension is: the hydroxyapatite of 3-9g (such as 3g, 5g, 7g, 9g, preferably 3g) is dissolved in 20-100mL (such as 20mL, 40mL, 60mL, 80mL, 100 mL, preferably 20 mL) water. The water is distilled water.

[0025] The above steps are specifically: the water is placed in the container, the container is placed on the magnetic stirrer, and the stirring speed is 5-10 rev / sec (such as 5 rev / sec, 7 rev / sec, 10 rev / sec, preferably 10 rev / sec). rev / sec), add hydroxyapatite dropwise to the container at a rate of 2-3 drops / min (such as 2 drops / min, 3 drops / min), after the dropwise addition of hydroxyapatite, homogenize 3 -5h (such as 3h, 4h, 5h, preferably 3h) to...

Embodiment 1

[0043] Step 1. Preparation of PLGA:

[0044] Accurately measure a certain amount of viscous liquid stannous isooctanoate, dissolve it in dichloromethane, and prepare a solution with a concentration of 1g / mL. Add 180g 82:18 monomer lactide and glycolide, 0.3mL molecular weight regulator tert-butyldimethylsilanol (commercial product), and 8mL above 1g / mL initiator stannous isooctanoate into the sealed tube of dichloromethane solution. The sealed tube was repeatedly evacuated and protected by argon gas, so that the pressure of the sealed tube reached 10 -3 pa. The sealed tube was placed in a 160 °C incubator, and the reactants in the sealed tube were melted after 5 h of reaction, and then shaken every 10 min for more than three times, and then reacted for 5 h. The product in the sealed tube was subjected to suction filtration with an intensity of 1 Mpa, and the obtained filter residue was dried at 60° C. for 3 hours to obtain PLGA.

[0045] Step 2. Preparation of controllable...

Embodiment 2

[0049] Step 1. Preparation of PLGA:

[0050] Accurately measure a certain amount of viscous liquid stannous isooctanoate, dissolve it in dichloromethane, and prepare a solution with a concentration of 0.5g / mL. Add 160g 50:50 monomer lactide and glycolide, 0.2mL molecular weight regulator tert-butyldimethylsilanol (commercially available product), and 10mL above 0.5g / mL initiator isooctoate into the sealed tube Tin in dichloromethane. The sealed tube was repeatedly evacuated and protected by argon gas, so that the pressure of the sealed tube reached 10 -3 pa. The sealed tube was placed in a 140°C incubator, and the reactants in the sealed tube were melted after reacting for 6 h, then shaken every 15 min for more than three times, and then reacted for 10 h. The product in the sealed tube was subjected to suction filtration with an intensity of 1.5 Mpa, and the obtained filter residue was dried at 80° C. for 4 hours to obtain PLGA.

[0051] Step 2. Preparation of controllable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com