Temperature-sensitive cyclodextrin polyrotaxane, and gel and preparation method thereof

A technology of polyrotaxane gel and cyclodextrin, which is applied in the field of temperature-sensitive polyrotaxane gel and its preparation, and can solve the problems of cyclodextrin primitives not having intelligent response characteristics, weak material response ability, and wheel slippage problems such as resistance to rotational movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, see figure 1 , using different end-capping groups to prepare polyrotaxanes that undergo controllable chain-degradation under specific external stimuli, and modify alkoxy ethers and hydrazide units on cyclodextrins, the number of cyclodextrins in polyrotaxanes, The number of alkoxy ether units and hydrazide units on each cyclodextrin is shown in Table 1, where PRX UV -DEG 9.6 -N 1.4 Dissociated polyrotaxanes by UV light, PRX red -DEG 9.3- N 0.6 For the reduction of dissociated polyrotaxanes, PRX non-DEG 8.4 -N 0.7 It is a non-degradable polyrotaxane.

[0033] Table 1. Characterization of PRXs

[0034]

Embodiment 2

[0036] In this embodiment, a method for preparing a temperature-sensitive slip gel that stimulates dissociation, the steps are as follows:

[0037] Sliding gels were prepared by using the hydrazide linkage reaction between hydrazide and aldehyde groups, and polyethylene glycol dibenzyl aldehyde (PEG-CHO) was used as a cross-linking agent. The specific experimental steps are as follows: First, prepare a buffer solvent of sodium acetate and acetic acid with pH = 4.53, and then weigh the polyrotaxane PRX-DEG-N and PEG-CHO obtained in Example 1, wherein hydrazide: aldehyde group = 1 :1 (molar ratio), add the mixed solvent of pH=4.53:THF=1:1 to dissolve completely (solid content is 15wt%), finally the solution of two substances is mixed in the ice bath, make it fully with the shaker Mix and let stand overnight in a 5°C refrigerator. Crack the glass sample bottle of the prepared gel, take out the prepared gel, place it in THF and deionized aqueous solution, replace the solvent 3-4 ...

Embodiment 3

[0043] In this embodiment, carry out slip gel rheological property test:

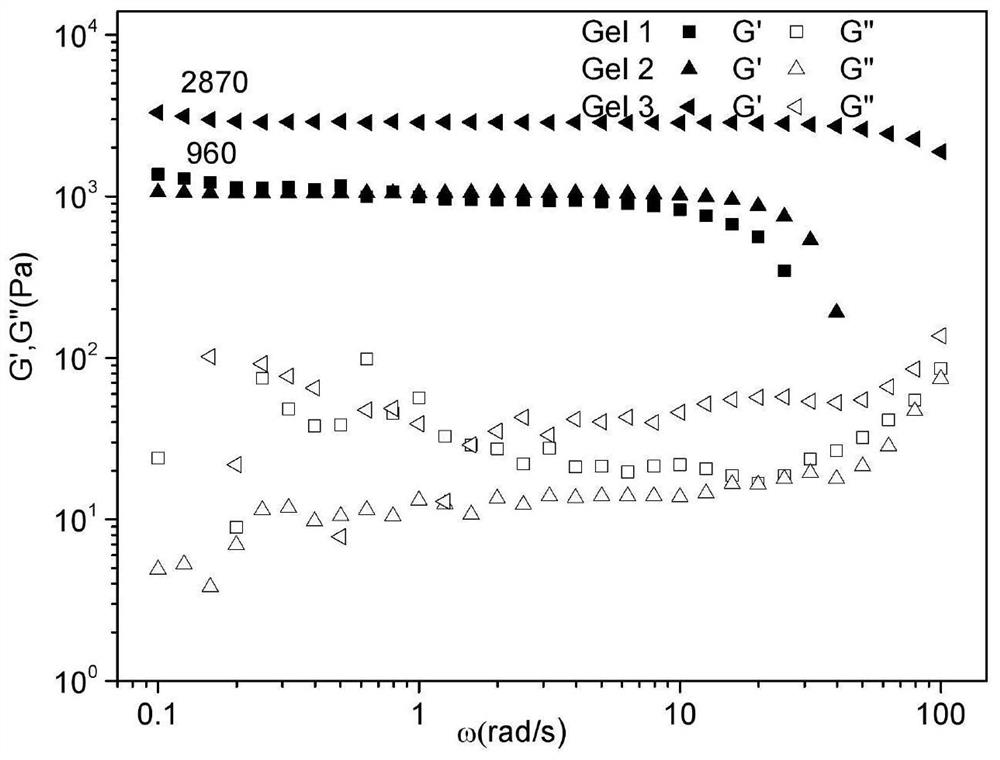

[0044] Different types of polyrotaxane gels prepared in Example 2 were subjected to rheological tests. The prepared slip gel has an average sample diameter of 10 mm and a thickness of 4 mm. Use a rotational rheometer to perform a frequency sweep on the gel sample, with a fixed strain of 0.5%, and a frequency range of 0.1-100rad / s. The rheological properties are as follows: figure 1 As shown, the storage modulus G' of Gel 1 and Gel 2 is about 960Pa, while the storage modulus of Gel 3 is 2870Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com