Modified silicone elastomer and preparation method thereof

A technology of silicon elastomer and modified silicon, which is applied in the field of modified silicon elastomer and its preparation, can solve the problems of easy drying of silicon elastomer, poor hiding power, and easy rubbing of skin, so as to achieve the goal of not easy drying and spreading Good sex, strong covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

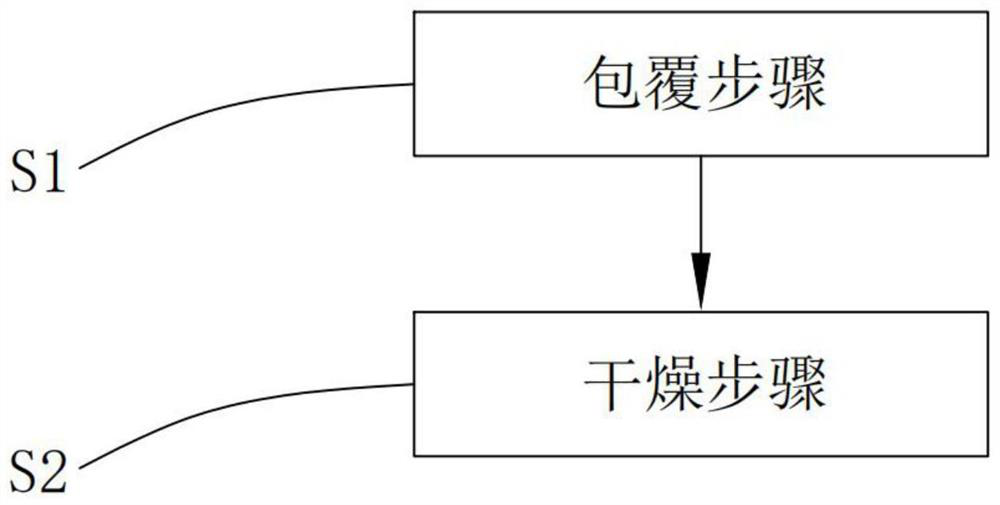

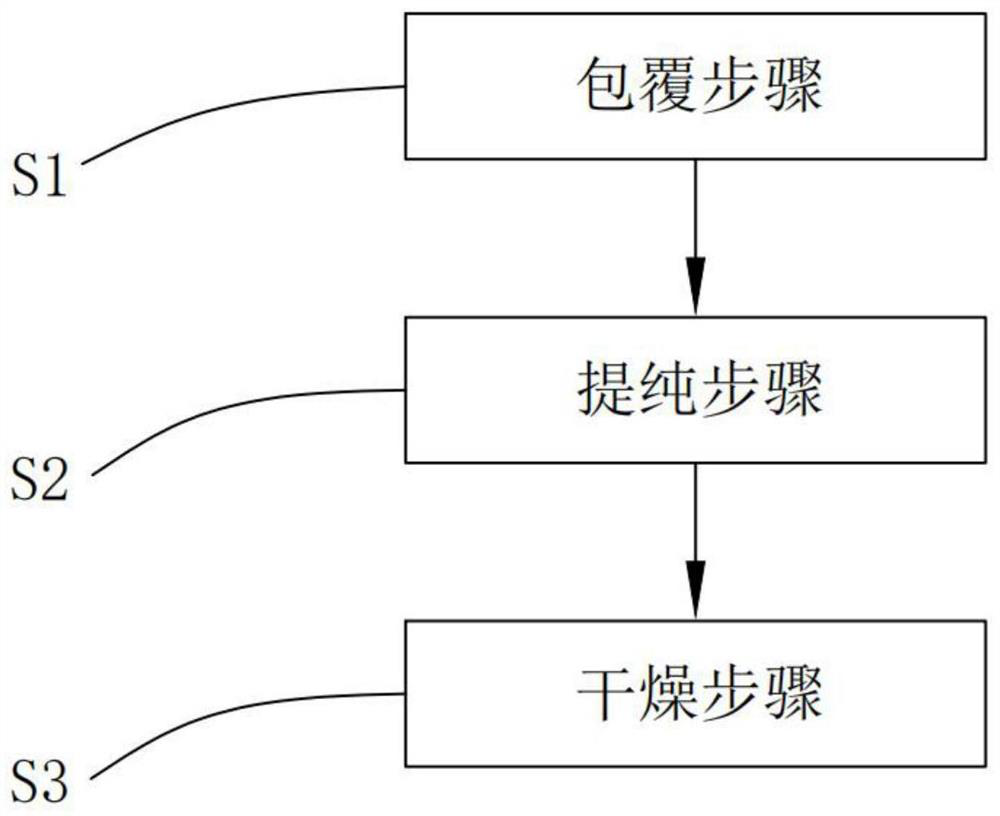

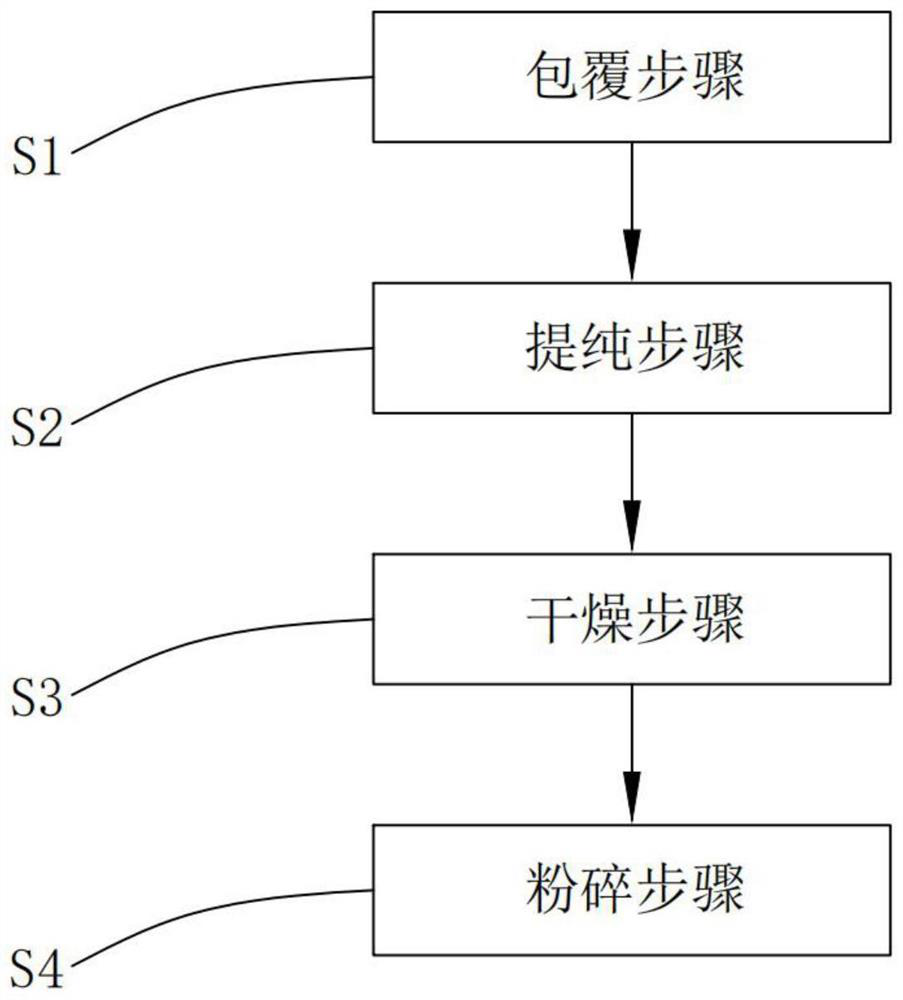

Method used

Image

Examples

Embodiment 1

[0055] At room temperature, add polymelline silicone and hydrogenated lecithin at a quality ratio of 5: 1 to a high -pressure average mixer for 10 minutes at high speed 5000rpm to obtain a mixture. Keep the sediment; spray dry at 95 ° C temperature to obtain modified silicon elastic virtual; finally, the dry -drying silicon elastic body is crushed in a high -speed crusher with a speed of 3400rpm. Essence

Embodiment 2

[0057] At room temperature, add polybikes siliconane / polymels siliconane interconnection polymer to hydrogenated lecithin at a quality ratio of 2: 1 to a high -pressure average mixer and mix at high speed 10000rpm for 12min to get a mixture; Wash the mixture 3 times and centrifuge to keep the deployment of the lower layer of precipitation; spray dry at 100 ° C temperature to get modified silicon elastic virtual; finally, the dry -ditable silicon elastic body is at a high speed of 3800rpm in a high -speed crusher. Make crushing to obtain powder -like altering silicon elastic body and record weight.

Embodiment 3

[0059] At room temperature, add polybikes siliconane / polymels siliconane interconnection polymer to hydrogenated lecithin at 5: 1 to high -pressure average mixer to mix high -speed 10000rpm and mix for 15 minutes to get a mixture; Wash the mixture 3 times and centrifuge to keep the sediment; spray dry at 96 ° C temperature to get a modified silicon elastic body; finally, the dry -modified silicon elastic body is at a high speed of 3000rpm in a high -speed crusher. Make crushing to obtain powder -like altering silicon elastic body and record weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com