Nano hydrated silicon dioxide super-hydrophobic modification preparation method

A technology of hydrated silica and superhydrophobic modification, which is applied in the chemical industry, climate sustainability, sustainable manufacturing/processing, etc., and can solve problems such as low efficiency, high energy consumption, and affecting the acid-base balance of the organic phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

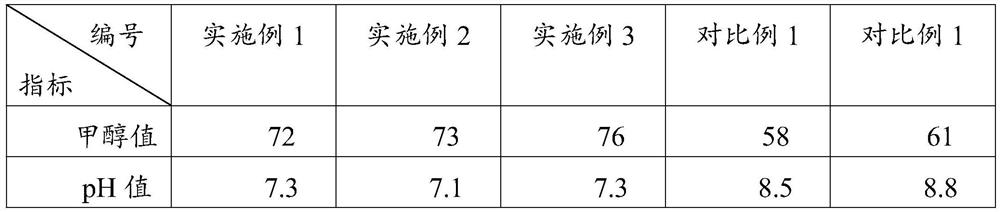

Examples

Embodiment 1

[0022] A preparation method for superhydrophobic modification of nano-hydrated silica, comprising the following steps:

[0023] Step 1: Coupling agent hydrolysis: Weigh 5kg of hexamethyldisilazane, 2kg of A-171 respectively, add the hydrolyzed solution prepared by 1kg of 15% acetic acid, 2kg of water, 1kg of polyethylene glycol and 1kg of ethanol for hydrolysis. , the coupling agent hydrolyzate must be used up within 1 hour;

[0024] Step 2: Add 100kg of nano-hydrated silica into the closed reaction kettle, and start stirring and heating at the same time. After the addition of nano-hydrated silica is completed, increase the stirring speed to a rotating speed of 30 rpm, so that the nano-hydrated silica is in the The closed reaction medium is stirred at high speed into a fluid state;

[0025] Step 3: After the temperature of the material in the kettle rises to 100° C., spray the coupling agent after hydrolysis in step 1 into the reaction kettle by atomization, and the injection...

Embodiment 2

[0029] A preparation method for superhydrophobic modification of nano-hydrated silica, comprising the following steps:

[0030] Step 1: Coupling agent hydrolysis: Weigh 4.5kg of hexamethyldisilazane and 2.5kg of A-151, respectively, and add 1kg of 12% acetic acid, 2kg of water, 1.2kg of polyethylene glycol and 1.5kg of ethanol. The hydrolyzed solution is hydrolyzed, and the coupling agent hydrolyzed solution must be used up within 1 hour;

[0031] Step 2: Add 100kg of nano-hydrated silica into the closed reaction kettle, and start stirring and heating at the same time. After the addition of nano-hydrated silica is completed, increase the stirring speed to a rotating speed of 30 rpm, so that the nano-hydrated silica is in the The closed reaction medium is stirred at high speed into a fluid state;

[0032] Step 3: After the temperature of the material in the kettle rises to 110°C,

[0033] The coupling agent after hydrolysis in step 1 was sprayed into the reaction kettle by at...

Embodiment 3

[0037] A preparation method for superhydrophobic modification of nano-hydrated silica, comprising the following steps:

[0038] Step 1: Coupling agent hydrolysis: Weigh 4.5kg of hexamethyldisilazane, 1kg of A-151 and 1kg of KH560, respectively, and add them to 1kg of 10% acetic acid, 2.5kg of water, 1.5kg of polyethylene glycol and 2kg of ethanol. The resulting hydrolyzed solution is hydrolyzed, and the coupling agent hydrolyzed solution must be used up within 1 hour;

[0039] Step 2: Add 100kg of nano-hydrated silica into the closed reaction kettle, and start stirring and heating at the same time. After the addition of nano-hydrated silica is completed, increase the stirring speed to a rotating speed of 30 rpm, so that the nano-hydrated silica is in the The closed reaction medium is stirred at high speed into a fluid state;

[0040] Step 3: After the temperature of the material in the kettle rises to 110°C,

[0041] The coupling agent after hydrolysis in step 1 was sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com