Preparation method and preparation system of high-purity nano-selenium powder

A nano-selenium powder, high-purity technology, applied in the field of high-purity nano-selenium powder preparation method and its preparation system, can solve the problems of low efficiency of plant active selenium, unable to meet the basic needs of human beings, etc., achieve rapid preparation, suitable for popularization of production and Simple and convenient application and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

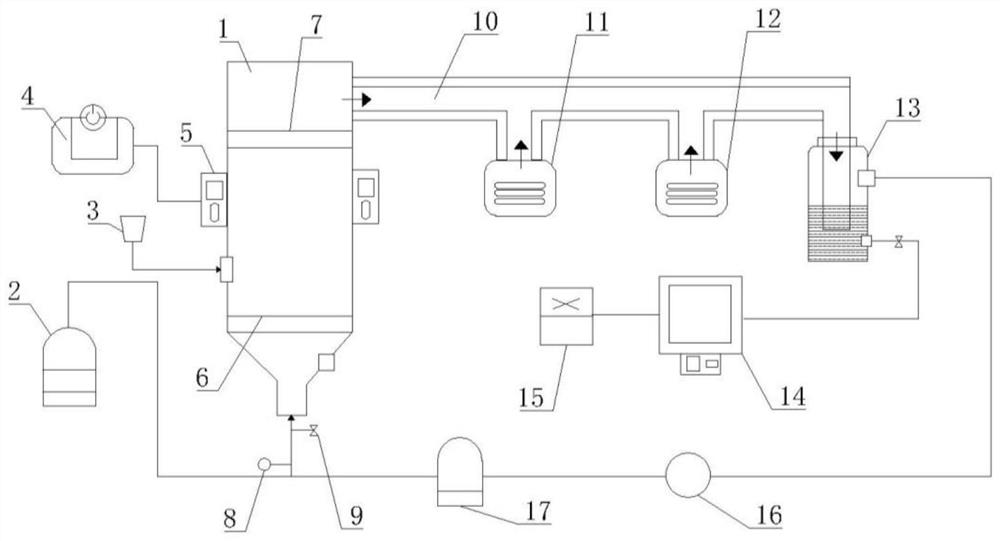

Image

Examples

Embodiment 1

[0030] The preparation method of the high-purity nano-selenium powder described in the present embodiment comprises the steps:

[0031] 1) The crude selenium raw material and high-purity oxygen react under the condition of microwave heating to form selenium oxide, and the selenium oxide is sublimated. This step is carried out in a fluidized bed, and the temperature in the fluidized bed is maintained at 550 ° C by microwave heating. High-purity oxygen The purity is greater than 99.99%, and the rate at which high-purity oxygen is passed into the fluidized bed is 300ml / s.

[0032] 2) The sublimated selenium oxide is combined with high-purity atomized water, and then undergoes a reduction reaction with an atomized reducing agent to obtain nano-scale selenium particles; the atomized water is produced by the first atomization device, and the impurities in the high-purity atomized water The content is less than 0.1mg / L, the conductivity is less than 0.1μs / cm, the atomized reducing ag...

Embodiment 2

[0035] The preparation method of the high-purity nano-selenium powder described in the present embodiment comprises the steps:

[0036] 1) The crude selenium raw material and high-purity oxygen react under the condition of microwave heating to generate selenium oxide, and the selenium oxide is sublimated. This step is carried out in a fluidized bed, and the temperature in the fluidized bed is maintained at 520-580 ° C by microwave heating. The purity of the pure oxygen is greater than 99.99%, and the rate of passing the high-purity oxygen into the fluidized bed is 30-500ml / s.

[0037] 2) The sublimated selenium oxide is combined with high-purity atomized water, and then undergoes a reduction reaction with an atomized reducing agent to obtain nano-scale selenium particles; wherein the high-purity atomized water is produced through the first atomization device, and the high-purity atomized water The water impurity content is less than 0.1mg / L, the conductivity is less than 0.1μs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com