Establishment method of intelligent water adding model for loosening and moisture regaining processes of tobacco shred making workshop

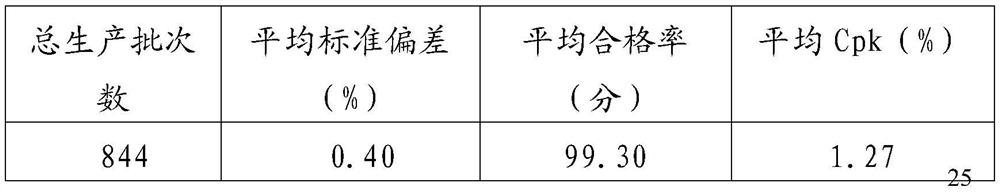

A technology of loose moisture recovery and method establishment, which is applied in sustainable manufacturing/processing, tobacco preparation, and comprehensive factory control. It can solve the problems of insufficient control accuracy of moisture content at the outlet of loose moisture moisture, so as to improve accuracy and uniformity and reduce fluctuations. , the effect of reducing process fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present application are described in detail below through the examples. The following examples are only exemplary and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be interpreted as limitations on the technical solutions of the present invention.

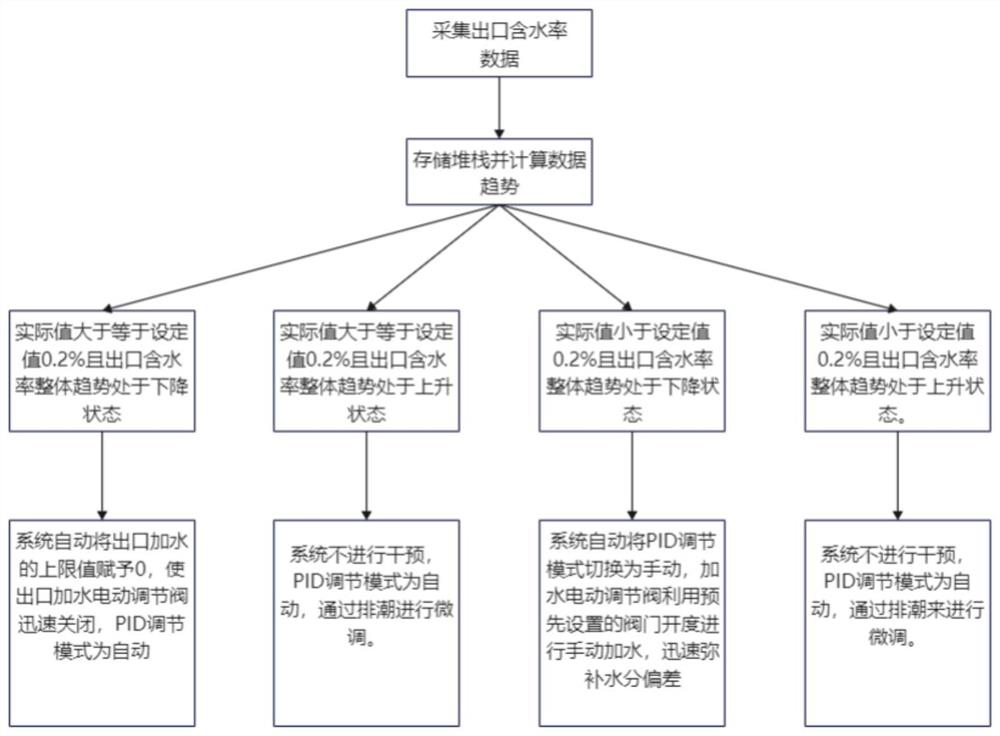

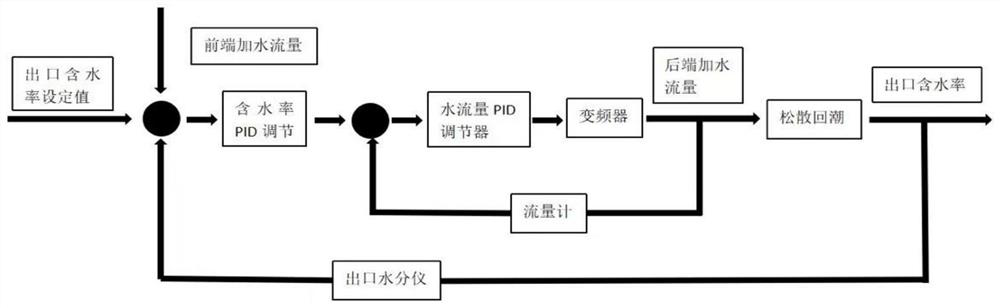

[0040] The application provides a method for establishing an intelligent water-adding model for the loosening and moisturizing process in a silk-making workshop, comprising the following steps:

[0041] S1. Provide uniform cigarette blocks after slicing to the loosening and moisturizing process, so as to improve the stability of the incoming materials in the loosening and moisturizing process.

[0042] S11. In order to avoid that the laying height and gap of the inlet cigarette blocks may affect the detection data, a deflector is installed on the inlet conveyor belt of the slicer to correct the cigarette packets to be cut. In the technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com