Manufacturing method of high-temperature-resistant, high-pressure-resistant and self-adaptive nonmetal composite sealing ring

A composite sealing and manufacturing method technology, applied in the field of sealing rings, can solve the problems of premature failure of the sealing ring, long processing time, and low service life of the sealing ring, and achieves small initial loading force, reduced installation difficulty, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

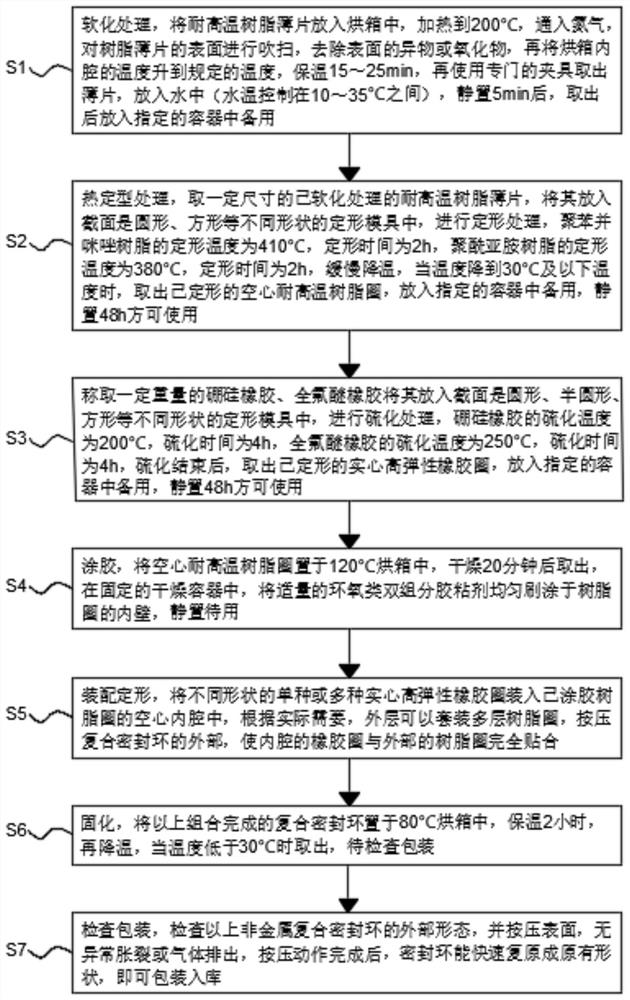

Method used

Image

Examples

Embodiment example 1

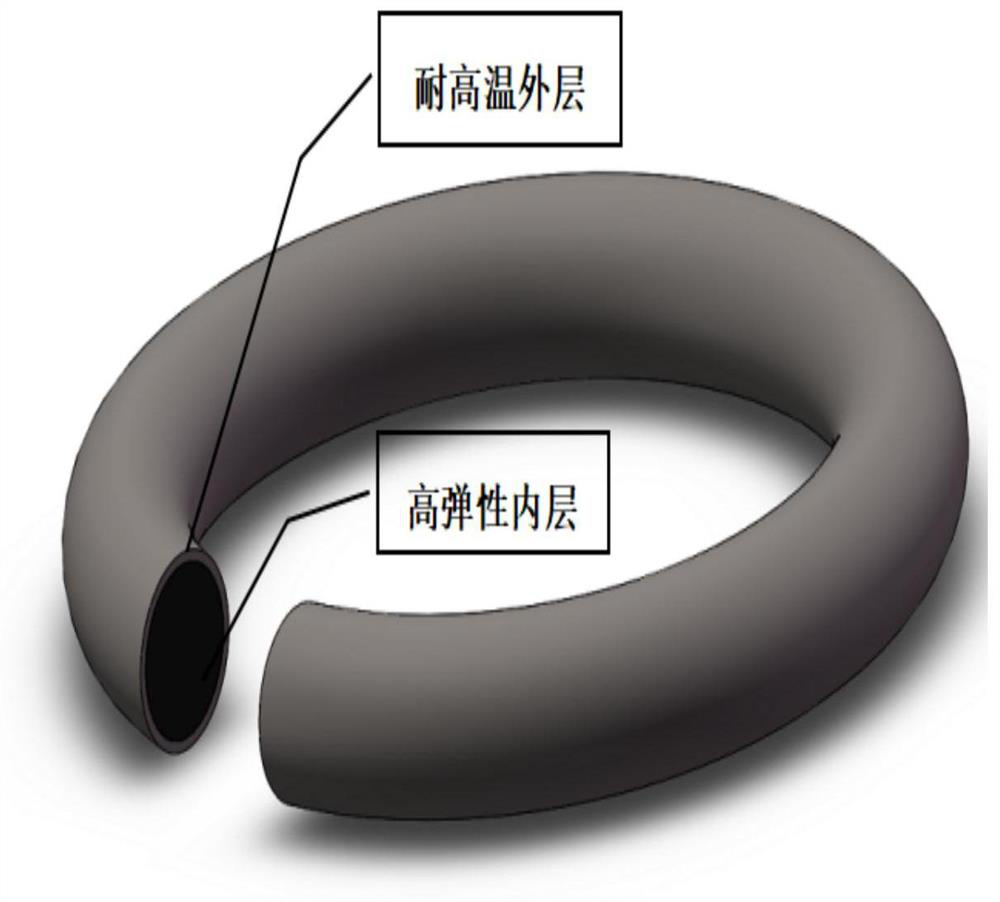

[0044] The high temperature, high pressure and self-adaptive non-metallic composite sealing ring made in this case contains a single layer of a single resin outer layer and a single rubber inner layer, which is suitable for high temperature (400℃) and high pressure (200MPa) working conditions in general. The specific production steps are as follows:

[0045] S101: Put a 0.2mm-thick polybenzimidazole resin sheet into an oven, heat it to 200°C, and introduce nitrogen gas to purge the surface of the resin sheet to remove foreign matter or oxides on the surface, and then set the temperature of the inner cavity of the oven to Raise it to the specified temperature (380°C), keep it warm for 15 minutes, then use a special fixture to take out the sheet, put it into water (the water temperature is controlled between 10 and 35°C), and let it stand for 5 minutes, then take it out and put it in a designated container for use. .

[0046] S201: Take the above softened resin sheet, put it in...

Embodiment example 2

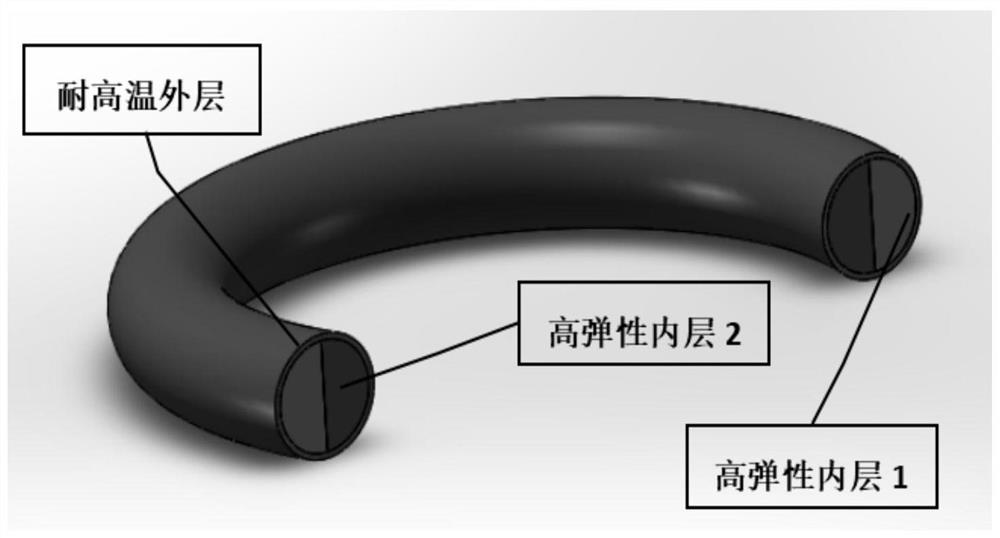

[0053] The high temperature, high pressure and self-adaptive non-metallic composite sealing ring made in this case contains a single layer of a single resin outer layer and two rubber composite inner layers, suitable for high temperature (400 ° C), high pressure ( 200MPa) working condition. The specific production steps are as follows:

[0054] S102: Put the 0.2mm-thick polyimide resin sheet into an oven, heat it to 200°C, pass nitrogen gas, and purge the surface of the resin sheet to remove foreign matter or oxides on the surface, and then set the temperature of the inner cavity of the oven to Raise it to the specified temperature (330°C), keep it warm for 15min, then use a special fixture to take out the sheet, put it in water (the water temperature is controlled between 10 and 35°C), let it stand for 5 minutes, take it out and put it in the designated container for later use .

[0055] S202: Take the above softened resin sheet, put it into a setting mold with a circular c...

Embodiment example 3

[0062] The high temperature, high pressure and self-adaptive non-metallic composite sealing ring produced in this case contains two outer layers of two resins and a single inner layer of rubber, which is suitable for high temperature (400℃) and high pressure (200MPa) with high temperature change frequency. ) working condition. The specific production steps are as follows:

[0063] S103: Put 0.15mm-thick polyimide resin and polybenzimidazole resin sheets into an oven respectively, heat to 200°C, pass nitrogen gas, and purge the surface of the resin sheet to remove foreign matter or oxides on the surface , and then raise the temperature of the inner cavity of the oven to the specified temperature (the temperature of the processed polybenzimidazole resin sheet is set to 380°C, and the temperature of the processed polyimide resin sheet is set to 330°C), keep it for 20 minutes, and then use a special The jig takes out the sheet, puts it into water (the water temperature is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com