PETG coating as well as raw material composition, preparation method and use method thereof

A raw material composition and coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor UV aging resistance, VOC emission, large amount of matting powder, etc. The effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

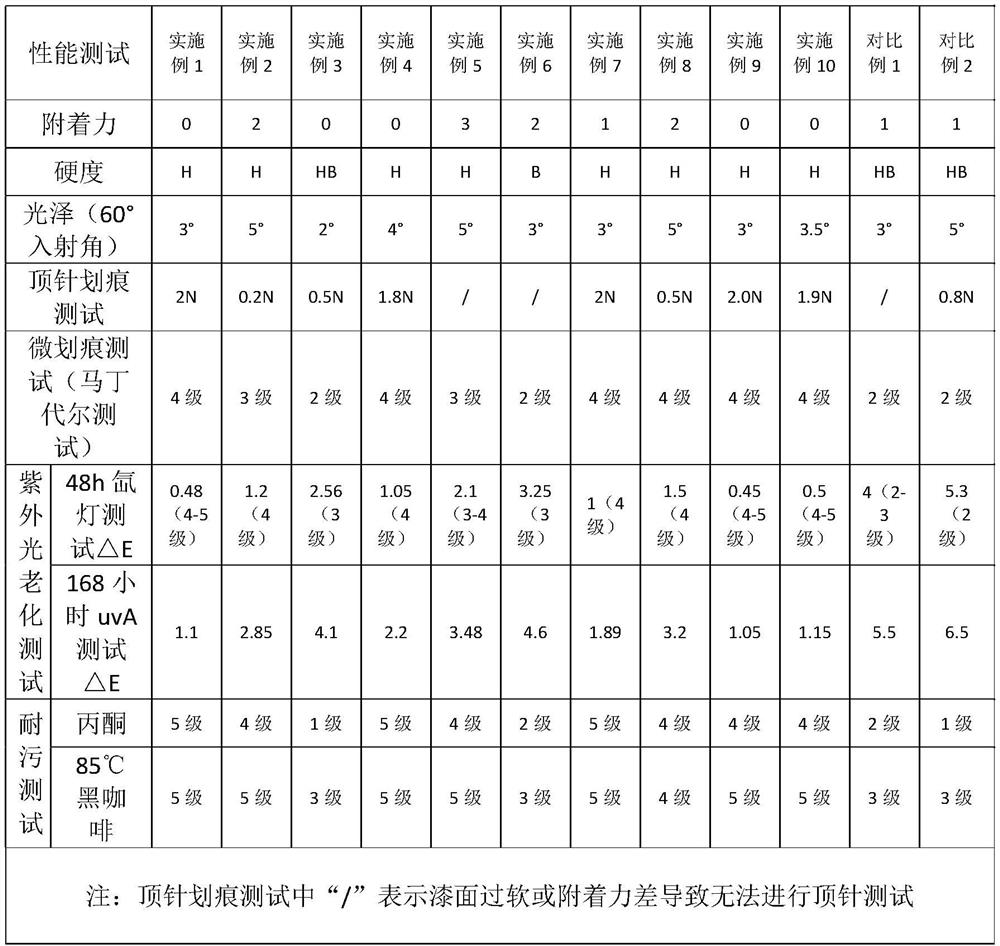

Examples

Embodiment 1

[0037] This embodiment provides a PETG coating, the raw material composition of the PETG coating is 25% by weight of hexafunctional urethane acrylate, 40% of trifunctional urethane acrylate, 15% of bifunctional reactive monomer, 1.5% by weight 7% of 2000 mesh silicon powder, 2% of 40nm alumina powder, 1% of Teflon powder, 2% of UV absorber, 0.5% of antioxidant, 3% of matting powder, 0.5% of Dispersant, 0.2% defoamer, 0.3% rheology aid and 2% surface aid.

[0038] In this embodiment, the hexafunctional urethane acrylate is the UX5400W product produced by Nippon Kayaku Chemical; the trifunctional urethane acrylate is the 0038M product produced by Guangdong Haohui Chemical; the bifunctional active monomer is hexanediol diacrylic acid Ester, the EM221 product produced by Changxing Chemical is selected; the wax powder is the PTFE wax powder, and the BYK CERAFLOUR 996 product of BAK Chemical is selected; the Teflon micropowder is the 9207Z product produced by 3M; UV absorber The BP...

Embodiment 2

[0044] This embodiment provides a PETG coating, and the raw material composition of the PETG coating is 30% by weight of hexafunctional urethane acrylate, 42% of trifunctional urethane acrylate, 10% of bifunctional reactive monomer, 1.5% by weight wax powder, 5% 2000 mesh silicon powder, 2% 40nm alumina powder, 1% Teflon powder, 2% UV absorber, 0.5% antioxidant, 3% matting powder, 0.5% Dispersant, 0.2% defoamer, 0.1% rheology aid and 2.2% surface aid.

[0045]In this embodiment, the hexafunctional urethane acrylate is the UX5400W product produced by Nippon Kayaku Chemical; the trifunctional urethane acrylate is the L6380A product produced by Guangdong Sanqi Chemical; the bifunctional active monomer is hexanediol diacrylic acid Ester, the EM221 product produced by Changxing Chemical is selected; the wax powder is PTFE wax powder, and the BYK CERAFLOUR 996 product of BAK Chemical is selected; the Teflon micropowder is the 9207Z product produced by 3M; UV absorber The BP-12 prod...

Embodiment 3

[0048] This embodiment provides a PETG coating, the raw material composition of the PETG coating is 25% by weight of hexafunctional urethane acrylate, 35% of trifunctional urethane acrylate, 20% of bifunctional reactive monomer, 1.5% by weight wax powder, 8% 2000 mesh silicon powder, 2% 40nm alumina powder, 1% Teflon powder, 2% UV absorber, 0.5% antioxidant, 2.5% matting powder, 1% Dispersant, 0.2% defoamer, 0.3% rheology aid and 2% surface aid.

[0049] In this embodiment, the hexafunctional urethane acrylate is the UX5400W product produced by Nippon Kayaku Chemical; the trifunctional urethane acrylate is the zc6552 product produced by Guangdong Zicai Chemical; the bifunctional active monomer is hexanediol diacrylic acid Ester, the EM221 product produced by Changxing Chemical is selected; the wax powder is the PTFE wax powder, and the BYK CERAFLOUR 996 product of BAK Chemical is selected; the Teflon micropowder is the 9207Z product produced by 3M; UV absorber The BP-12 produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com