Ion exchange polymer microsphere and synthesis method thereof

A technology of ion exchange and synthesis method, which is applied in the field of microsphere preparation, can solve the problems of reducing separation efficiency, etc., and achieve the effects of easy experimental conditions, adjustment of experimental conditions, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a) configure an aqueous solution, including surfactant sodium lauryl sulfate 0.05g, hydrophilic monomer sodium styrene sulfonate 0.5g, and water 20g;

[0028] b) Prepare an oil solution, including 1.35 g of hydrophobic monomer styrene, 0.0225 g of hydrophobic cross-linking agent divinylbenzene, 0.1 g of hydrophobic polymer polystyrene (weight average relative molecular mass 35000), and 0.1 g of hydrophobic initiator azodiiso Nitrile 20mg, hydrophobic solvent chlorododecane 0.044g;

[0029] c) Mix the aqueous solution and the oil solution, and emulsify into a uniform oil-in-water emulsion by ultrasonication;

[0030] d) heating to 70°C to initiate monomer polymerization, and the reaction was carried out for 18h;

[0031] e) The product obtained from the reaction is washed with a solvent and freeze-dried to obtain a powder.

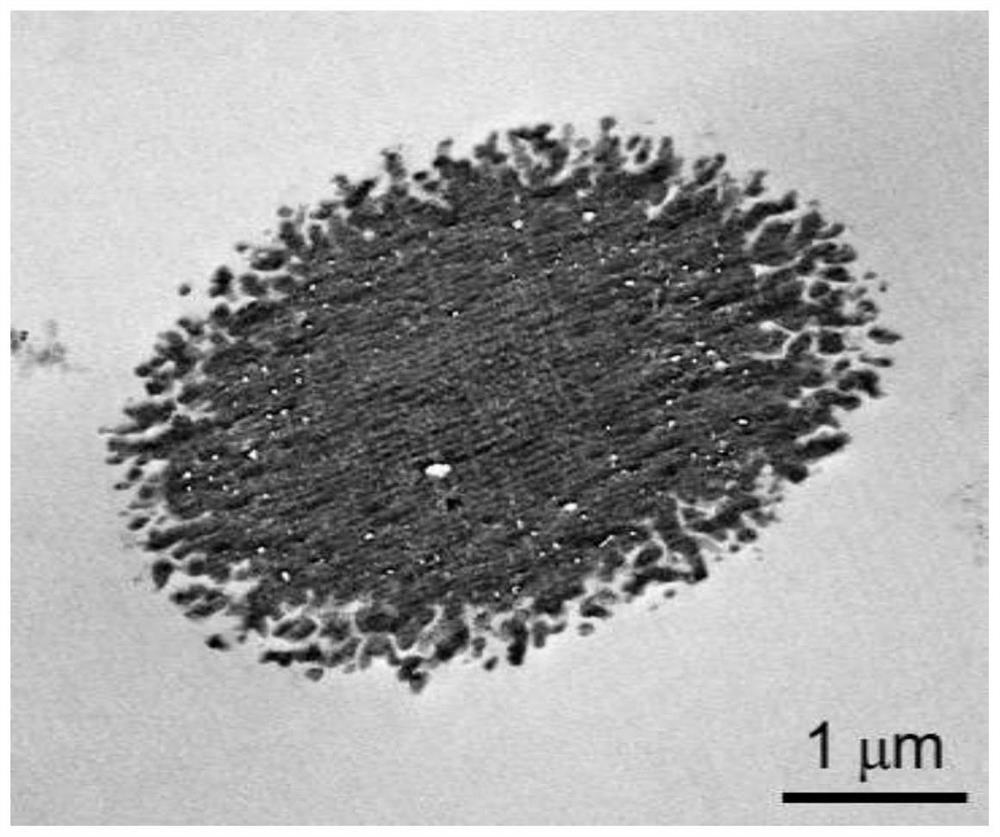

[0032] The diameter of the synthesized microspheres is 4.0μm±0.3μm by SEM characterization, the surface has a porous morphology, the size and morp...

Embodiment 2

[0034] a) Prepare an aqueous solution, including 0.3 g of polyethylene glycol as a surfactant, 0.7 g of sodium styrene sulfonate as a hydrophilic monomer, and 40 g of water;

[0035] b) Prepare an oil solution, including 2.7 g of hydrophobic monomer styrene and 0.045 g of hydrophobic cross-linking agent divinylbenzene

[0036] g, hydrophobic polymer polystyrene (weight average relative molecular mass 35000) 0.2g, hydrophobic initiator azobisisobutyronitrile 60mg, hydrophobic solvent chlorododecane 0.09g;

[0037] c) Mix the aqueous solution and the oil solution, and emulsify into a uniform oil-in-water emulsion by ultrasonication;

[0038] d) heating to 75°C to initiate monomer polymerization, and react for 12h;

[0039] e) The product obtained from the reaction is washed with a solvent and freeze-dried to obtain a powder.

[0040] The diameter of the synthesized microspheres is 3.5μm±0.2μm by SEM characterization, the surface has a porous morphology, the size and morphology...

Embodiment 3

[0042] a) configure an aqueous solution, including surfactant sodium lauryl sulfate 0.5g, hydrophilic monomer sodium styrene sulfonate 6.5g, and water 200g;

[0043] b) Prepare an oil solution, including 15g of hydrophobic monomer styrene and 0.225 g of hydrophobic crosslinking agent divinylbenzene

[0044] g, hydrophobic polymer polystyrene (weight average relative molecular mass 45000) 1.2g, hydrophobic initiator azobisisobutyronitrile 200mg, hydrophobic solvent chlorododecane 0.44g;

[0045] c) Mix the aqueous solution and the oil solution, and emulsify into a uniform oil-in-water emulsion by ultrasonication;

[0046] d) heating to 70°C to initiate monomer polymerization, and the reaction is carried out for 72h;

[0047] e) The product obtained from the reaction is washed with a solvent and freeze-dried to obtain a powder.

[0048] The diameter of the synthesized microspheres is 4.5μm±0.3μm by SEM characterization, the surface has a porous morphology, the size and morpholog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com