Numerical control machine tool machining center capable of conveniently clamping special-shaped workpiece

一种异形工件、数控机床的技术,应用在全面工厂控制、金属加工设备、金属加工机械零件等方向,能够解决异形工件夹持不稳固、降低数控加工精确性、不便工件观察等问题,达到方便观察、适配度高、便于观察的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

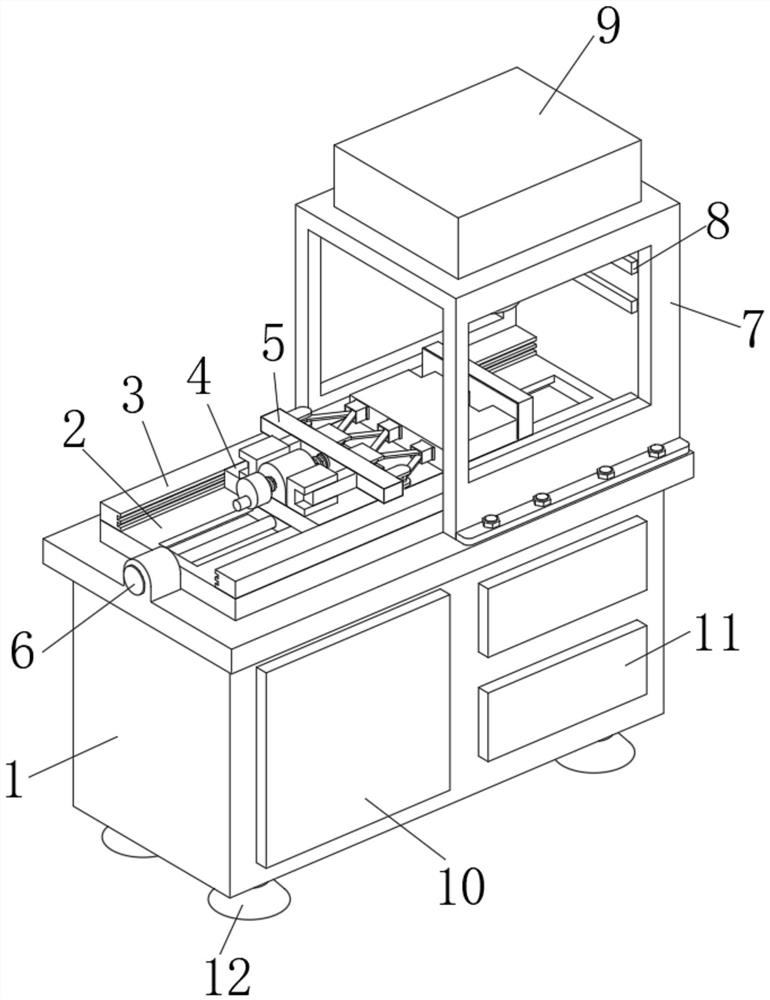

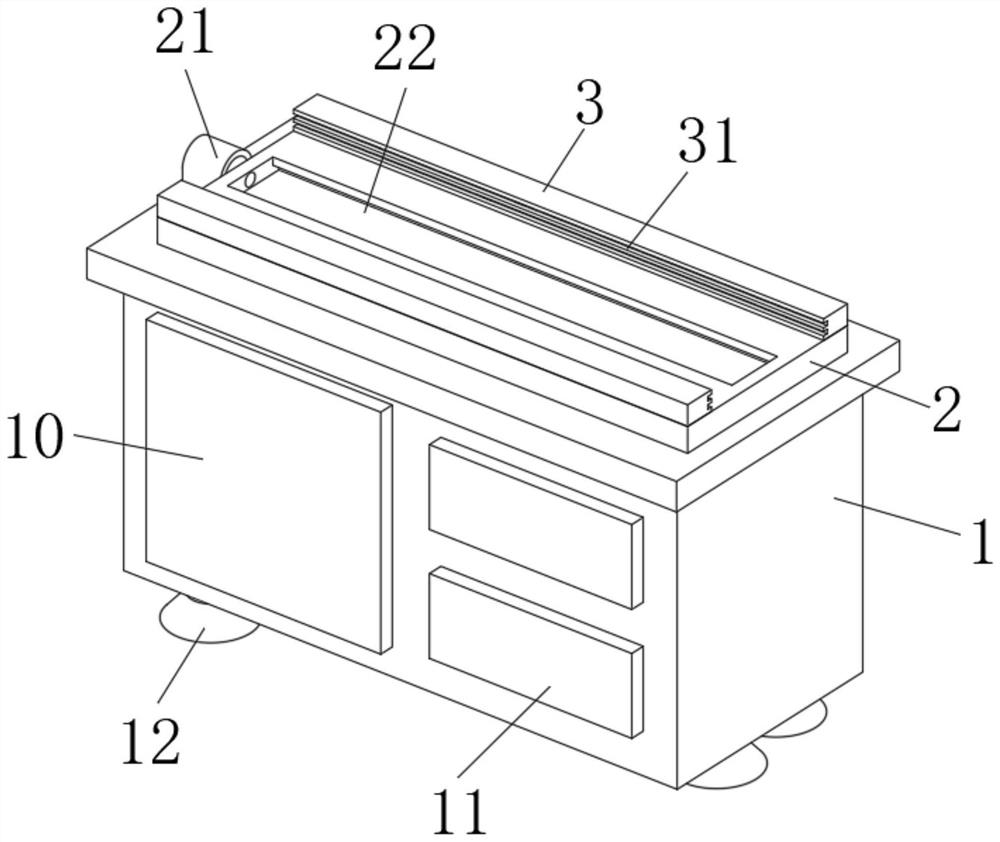

[0034]A CNC machine tool machining center that is convenient for clamping special-shaped workpieces, such as Figure 1-2 As shown, it includes an operating table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2, and a chute 22 is opened in the middle of the upper end of the fixed backing plate 2 , a side support plate 3 is fixedly installed on the front and rear sides of the upper end of the fixed backing plate 2, two sliding rails 31 are opened on the opposite ends of the two side support plates 3, and a moving mechanism 4 is slidably connected in the sliding groove 22. And the front and rear ends of the moving mechanism 4 are slidably connected with the slide rails 31, an electric telescopic rod 6 is fixedly installed in the fixed seat 21, and the electric telescopic rod 6 is fixedly connected with the left end of the moving mechanism 4, and t...

Embodiment 2

[0037] On the basis of Example 1, as Figure 3-7 As shown, a CNC machine tool machining center that is convenient for clamping special-shaped workpieces includes an operation table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, and a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2. A chute 22 is opened in the middle of the upper end of the fixed backing plate 2 , a side support plate 3 is fixedly installed on the front and rear sides of the upper end of the fixed backing plate 2 , and two sliding rails 31 are opened on the opposite ends of the two side support plates 3 . A moving mechanism 4 is slidably connected in the chute 22, and the front and rear ends of the moving mechanism 4 are slidably connected with the slide rail 31. An electric telescopic rod 6 is fixedly installed in the fixed seat 21, and the electric telescopic rod 6 is connected with the moving mechanism 4. The left end of t...

Embodiment 3

[0040] On the basis of Example 1, as Figure 8 As shown, a CNC machine tool machining center that is convenient for clamping special-shaped workpieces includes an operation table 1, a fixed backing plate 2 is fixedly installed in the middle of the upper end of the operating table 1, and a fixed seat 21 is fixedly welded on the left end of the fixed backing plate 2. A chute 22 is opened in the middle of the upper end of the fixed backing plate 2 , a side support plate 3 is fixedly installed on the front and rear sides of the upper end of the fixed backing plate 2 , and two sliding rails 31 are opened on the opposite ends of the two side support plates 3 . A moving mechanism 4 is slidably connected in the chute 22, and the front and rear ends of the moving mechanism 4 are slidably connected with the slide rail 31. An electric telescopic rod 6 is fixedly installed in the fixed seat 21, and the electric telescopic rod 6 is connected with the moving mechanism 4. The left end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com