Preparation method of emplastrum matrix capable of rapidly releasing volatile drugs

A plaster and matrix technology, applied in the field of pharmaceutical preparations, can solve the problems of waste of resources, insufficient release of drug dosage, etc., and achieve the effects of reducing waste of resources, significant social and economic benefits, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

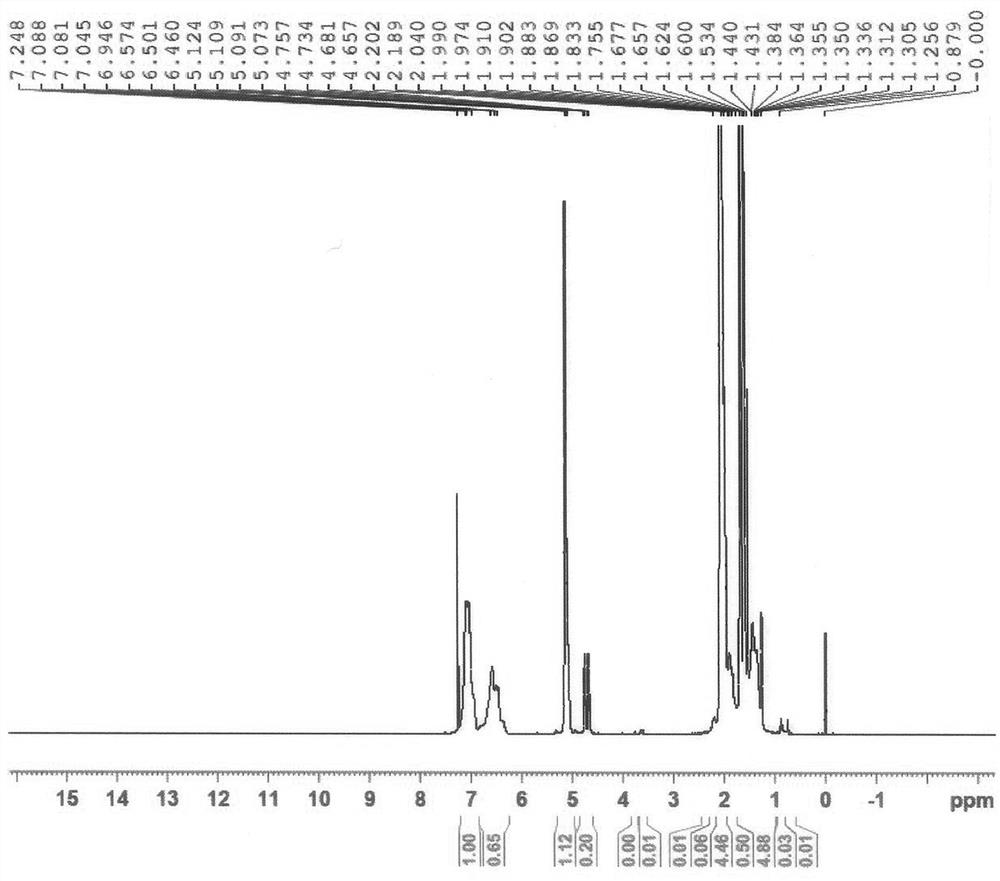

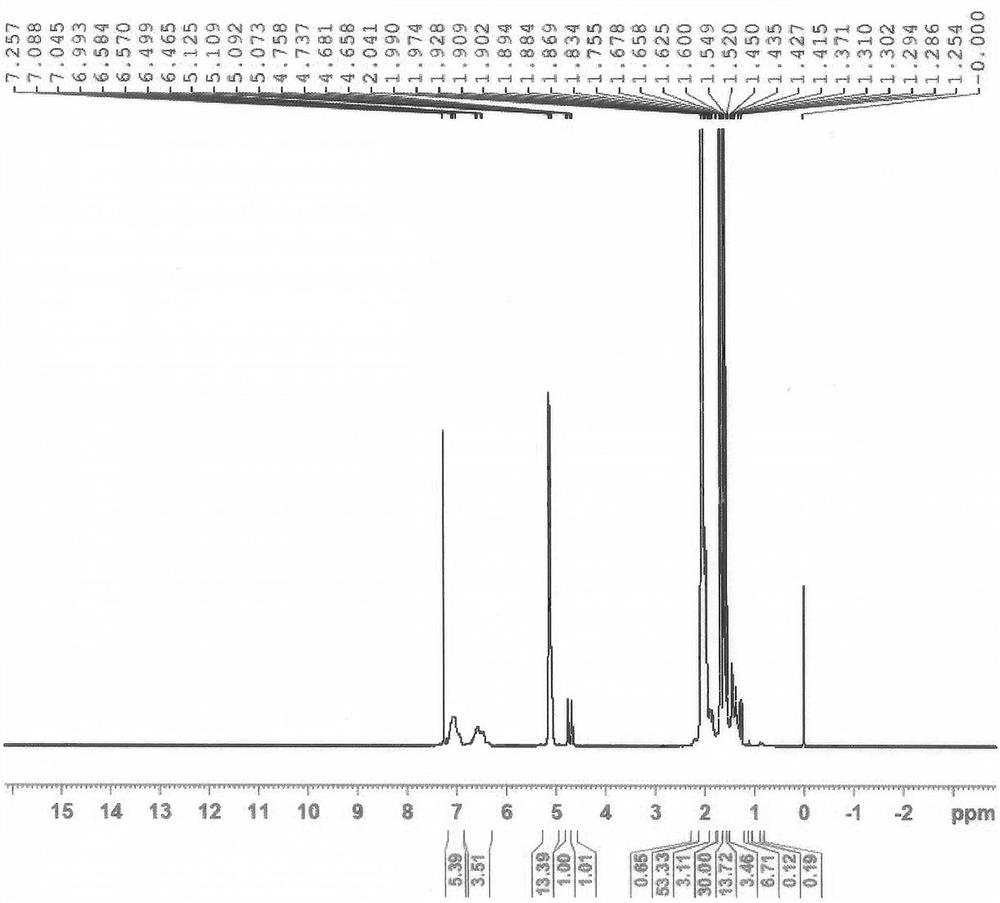

Image

Examples

Embodiment 1

[0019] A method for preparing a patch base for rapid release of volatile drugs, comprising the following steps:

[0020] (1), the synthesis of linear SIS block copolymer:

[0021] a. Heating and baking the reaction kettle and replacing it with nitrogen repeatedly to anhydrous and oxygen-free, then cooling to room temperature, then adding 1900mL cyclohexane to the reaction kettle, then adding 23g styrene, 1ml tetrahydrofuran and 5mL successively to a concentration of 1.5×10 -5 mol / L of n-butyllithium, the reaction kettle was heated to 40°C to initiate the first block polymerization reaction, and the reaction was carried out under the condition of 200rpm for 35min;

[0022] b. After the first block polymerization is completed, it is cooled to 25°C, and under nitrogen protection, 440g of isoprene monomer is added to the reaction kettle, and the temperature is raised to 45°C to initiate the second block polymerization reaction, and under the condition of 200rpm Stir the reaction ...

Embodiment 2

[0027] A method for preparing a patch base for rapid release of volatile drugs, comprising the following steps:

[0028] (1), the synthesis of linear SIS block copolymer:

[0029] a. Heating and baking the reaction kettle and replacing it with nitrogen repeatedly to anhydrous and oxygen-free, then cooling to room temperature, adding 2000 mL of cyclohexane to the reaction kettle, and then adding 25 g of styrene, 1.2 ml of tetrahydrofuran and 6 mL to a concentration of 1.5× 10 -5 mol / L of n-butyllithium, the reaction kettle was heated to 43 ° C, the first block polymerization was initiated, and the reaction was carried out under the condition of 230 rpm for 32 min;

[0030] b. After the first block polymerization is completed, it is cooled to 25 ° C, and under nitrogen protection, 450 g of isoprene monomer is added to the reaction kettle, and the temperature is raised to 48 ° C to initiate the second block polymerization reaction. Under the condition of 230 rpm Stir the reacti...

Embodiment 3

[0035] A method for preparing a patch base for rapid release of volatile drugs, comprising the following steps:

[0036] (1), the synthesis of linear SIS block copolymer:

[0037] a. Heating and baking the reaction kettle and replacing it with nitrogen repeatedly to anhydrous and oxygen-free, then cooling to room temperature, then adding 2100 mL of cyclohexane to the reaction kettle, then adding 26 g of styrene, 1.4 ml of tetrahydrofuran and 7 mL of 1.5× 10 -5mol / L of n-butyllithium, the reaction kettle was heated to 45 ° C, the first block polymerization was initiated, and the reaction was carried out under the condition of 250 rpm for 30 min;

[0038] b. After the first block polymerization is completed, it is cooled to 25°C, and under nitrogen protection, 460g of isoprene monomer is added to the reaction kettle, and the temperature is raised to 50°C to initiate the second block polymerization reaction. Under the condition of 250rpm Stir the reaction for 35min;

[0039] c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com