Method for enriching precious metal in electric furnace material

A precious metal and material technology, applied in the field of precious metal metallurgy, can solve the problems of difficult removal of impurity zinc and magnesium, difficulty in recovery, long extraction process of rhodium and iridium, etc., to achieve high-efficiency separation, simple process flow, and the effect of inhibiting trace leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

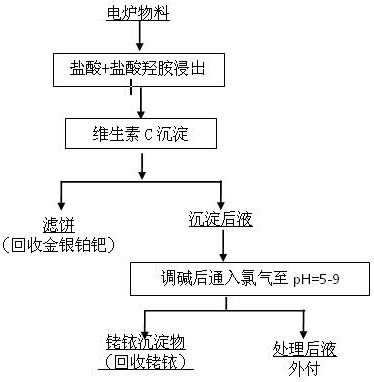

[0017] (1) Smelting and capturing 100g of iron-precious metal alloys produced during the precious metal smelting process in an electric arc furnace (the total content of precious metals is 2.2%), leaching with a volume fraction of 5% hydrochloric acid solution at 5°C for 8 hours, and adding 1g hydrochloric acid to the hydrochloric acid solution Hydroxylamine, leaching and filtering to obtain filter residue, the precious metal content in the filtrate is all ≤0.0005g / L, and the filtrate enters the wastewater treatment station for treatment;

[0018] (2) Dissolving the filter residue obtained in step (1) to make a solution, controlling the pH of the solution to be 0, adding vitamin C twice the mass of gold, silver, platinum and palladium in the solution, and reacting at 60 ° C for 1 hour and filtering, the gold and silver in the filter residue are filtered. The platinum and palladium (total content is 40.26%) are separated and refined;

[0019] (3) The filtrate obtained in step (...

Embodiment 2

[0021] (1) 1000g electric arc furnace smelting and capturing the iron-precious metal alloy produced in the precious metal smelting process (the total content of precious metals is 1.3%), and leaching with a volume fraction of 15% hydrochloric acid solution at 95°C for 12 hours, wherein hydroxylamine hydrochloride in the hydrochloric acid solution 50g, filter after leaching to obtain filter residue, the precious metal content in the filtrate is all ≤0.0002g / L, and the filtrate enters the wastewater treatment station for treatment;

[0022] (2) Dissolving the filter residue obtained in step (1) to make a solution, controlling the pH of the solution to be 2, adding vitamin C 5 times the mass of gold, silver, platinum and palladium in the solution, and reacting at 65 ° C for 2 hours and filtering, the gold and silver in the filter residue Platinum and palladium (total content of 35.07%) are separated and refined;

[0023] (3) The filtrate obtained in step (2) is heated to 90°C, so...

Embodiment 3

[0025] (1) Smelting and capturing 100kg of iron-precious metal alloys produced during the precious metal smelting process in an electric arc furnace (the total content of precious metals is 1.08%), and leaching with a volume fraction of 10% hydrochloric acid solution at 80°C for 10 hours, in which 1kg of hydroxylamine hydrochloride is contained in the hydrochloric acid solution. , leaching and filtering to obtain filter residue, the precious metal content in the filtrate is all ≤0.0008g / L, and the filtrate enters the wastewater treatment station for treatment;

[0026] (2) Dissolving the filter residue obtained in step (1) to make a solution, controlling the pH of the solution to be 1, adding vitamin C three times the mass of gold, silver, platinum and palladium in the solution, and reacting at 62 ° C for 1.5 hours and filtering, the gold and silver in the filter residue Platinum and palladium (total content is 32.11%) are separated and refined;

[0027] (3) The filtrate is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com