Heating-free digestion method and device for chemical analysis sample

A digestion device and chemical analysis technology, applied in the field of material analysis, can solve problems such as safety accidents, component contamination, and reagent splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

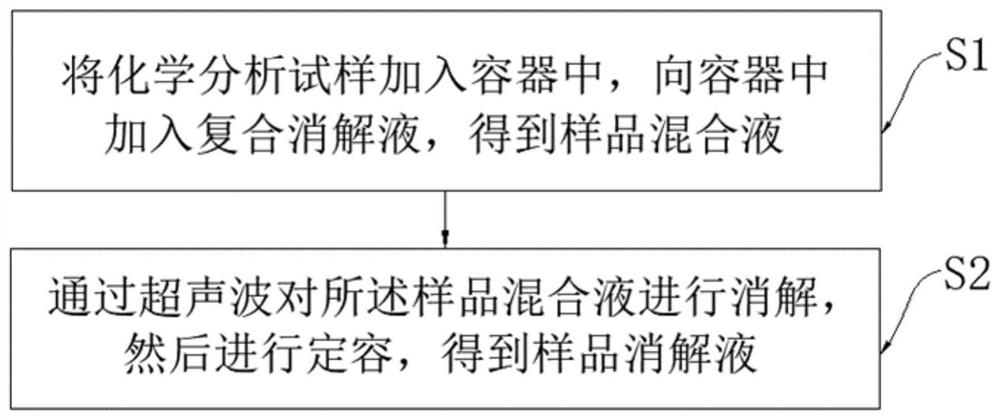

Method used

Image

Examples

Embodiment

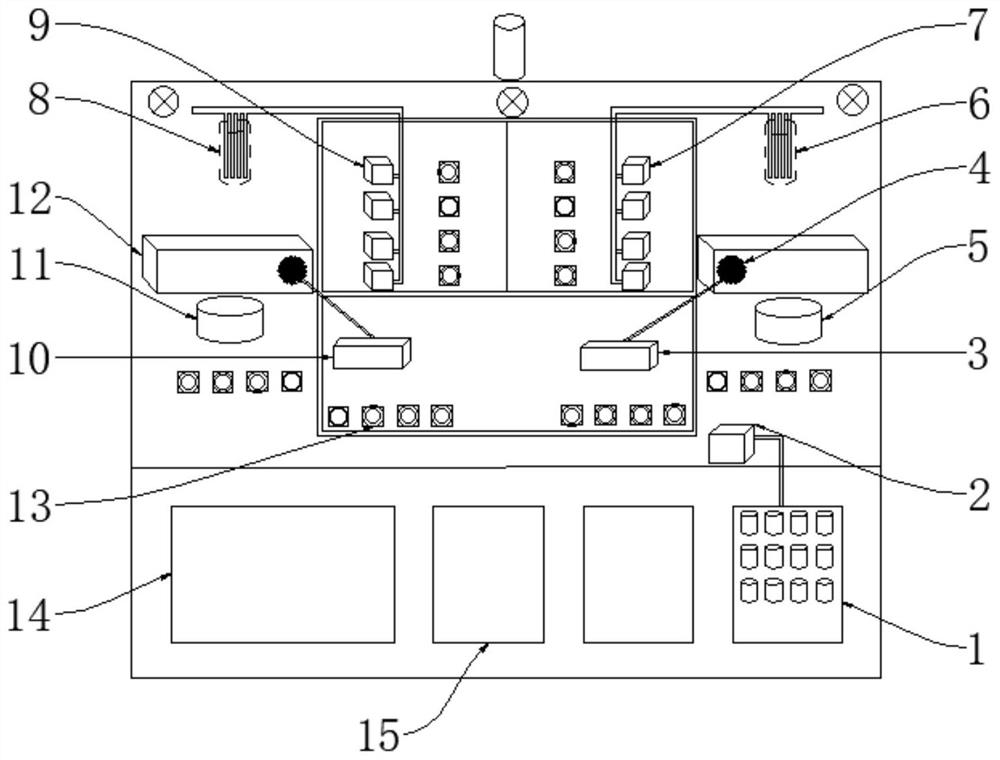

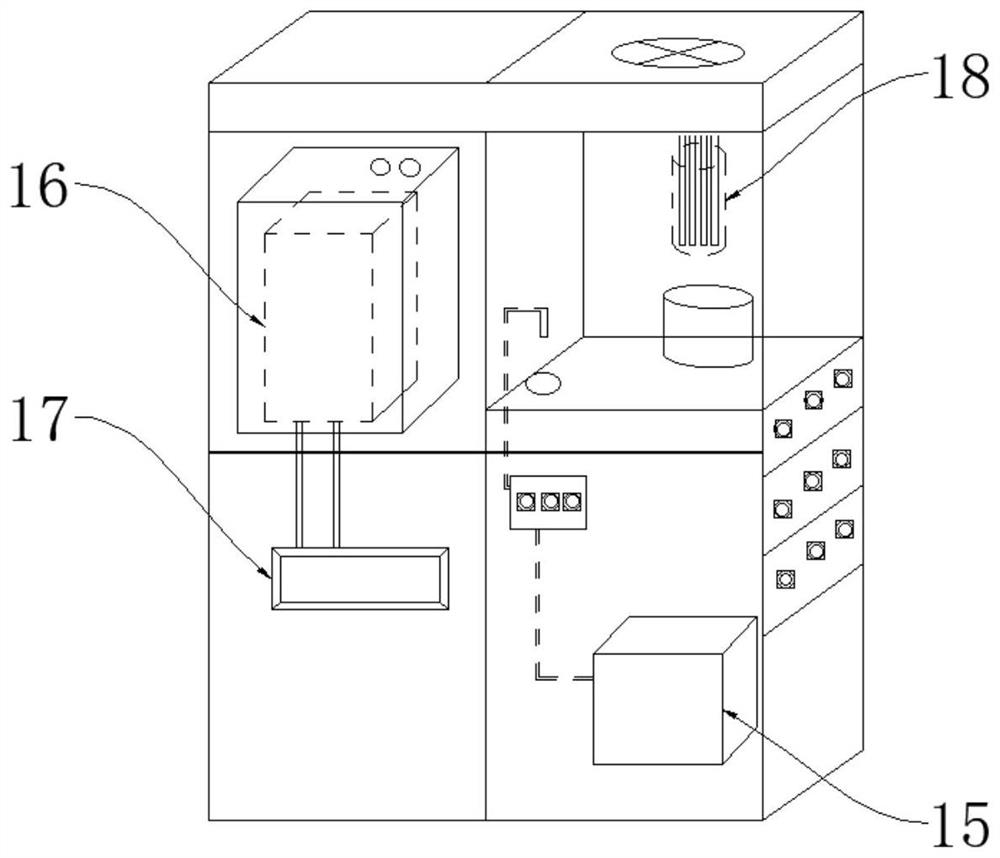

[0047] The structure of the heating-free digestion device for chemical analysis samples is as follows figure 2 and image 3 As shown, the constant temperature liquid storage tank 16 includes one low temperature liquid storage tank, one medium temperature liquid storage tank and two high temperature liquid storage tanks, wherein the low temperature liquid storage tank stores distilled water with a temperature of 4° C. Yttrium standard solution (0.1% yttrium nitrate solution) at 20°C, 1+2 nitric acid (1 volume of nitric acid and 2 volumes of pure water) and 1+1 hydrochloric acid at 50°C respectively stored in two high temperature storage tanks (1 volume of hydrochloric acid and 1 volume of pure water are compatible); set the pipetting parameters of each test solution, wherein, 1+2 nitric acid is 20mL, 1+1 hydrochloric acid is 20mL, yttrium standard solution is 10mL, and distilled water is 50mL; The digestion sample is GSB03-1316-201 low-carbon ferromanganese, which was ground ...

experiment example

[0054] Spectral analysis of the sample digestion solution obtained in the examples was carried out by ICP-AES, and the analysis items were silicon and phosphorus.

[0055] The analysis method is as follows: use a standard sample or a reference reagent to compound a standard solution for each mass concentration point of the ICP working curve, select an appropriate analytical line, test the standard solution, and establish a working curve of silicon and phosphorus; The mass fractions of silicon and phosphorus were obtained from the working curve by ICP-AES spectroscopic analysis. The obtained results were compared with the standard sample values, and the results are shown in Table 1:

[0056] Table 1 Comparison table between the analysis results of low carbon ferromanganese and the standard sample value (w%)

[0057]

[0058] As can be seen from Table 1, the error between the analysis result of the low-carbon ferromanganese detected by the embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com