Modification method of electrolytic hydrogen production anode, electrolytic hydrogen production anode and application

A modification and anode technology, applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of limited application, chloride ion corrosion, etc., achieve the effect of improving stability and selectivity, and delaying chloride ion corrosion anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Cut commercial nickel foam (as a conductive substrate) into strips of 1 cm × 3 cm, at 2 mol·L -1 Ultrasonic treatment for 3 min in hydrochloric acid solution, then ultrasonic cleaning for three times in deionized water and absolute ethanol respectively, and natural drying in air for use.

[0072] (2) Dissolve 130.8 mg of nickel nitrate hexahydrate, 60.6 mg of ferric nitrate nonahydrate and 300 mg of urea in 36 mL of deionized water to prepare a solvothermal reaction solution containing nickel and iron, and transfer it to a 50 mL polytetrafluoroethylene material reaction tank middle.

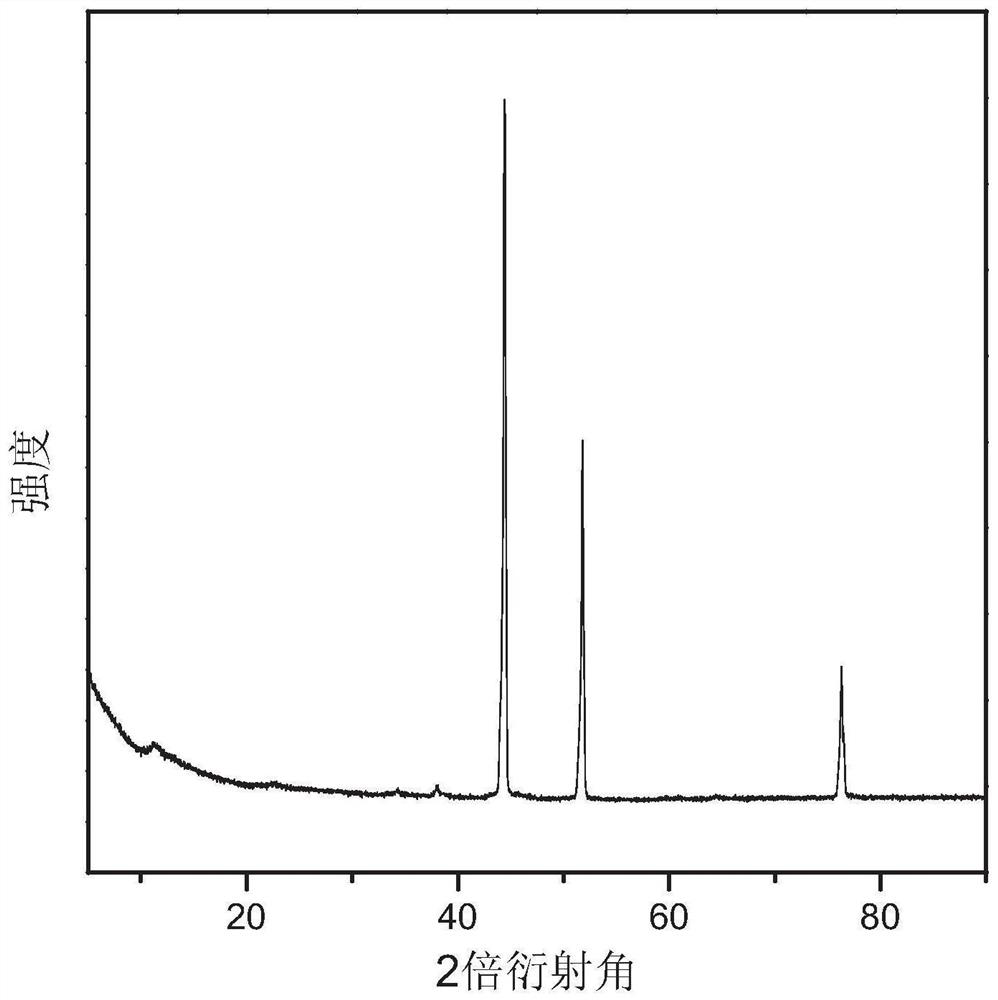

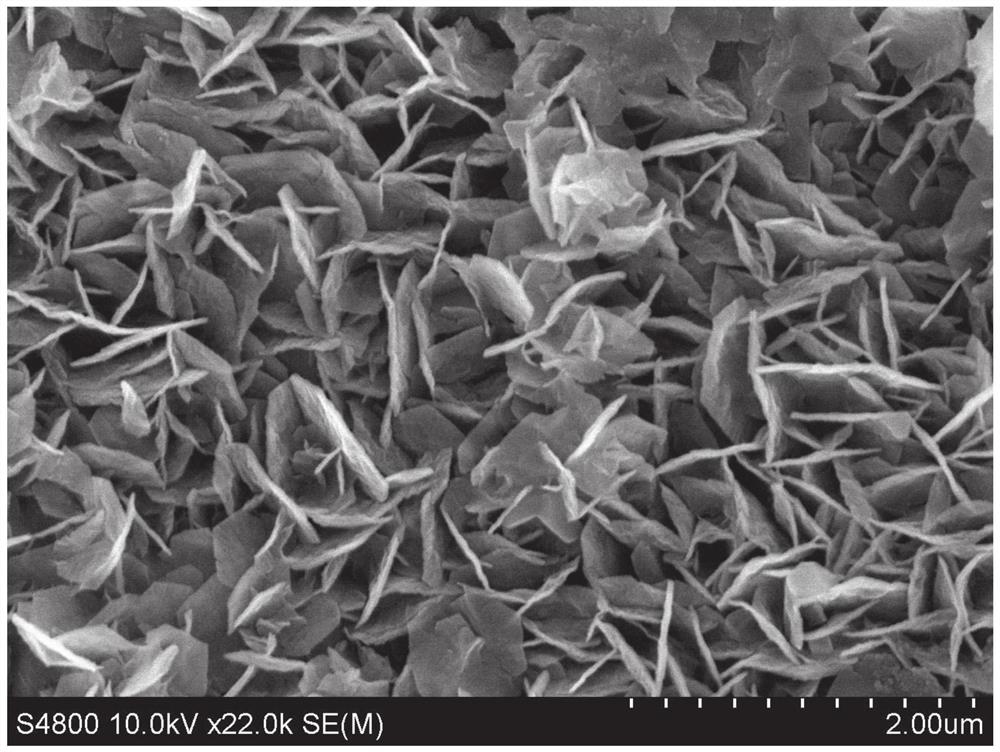

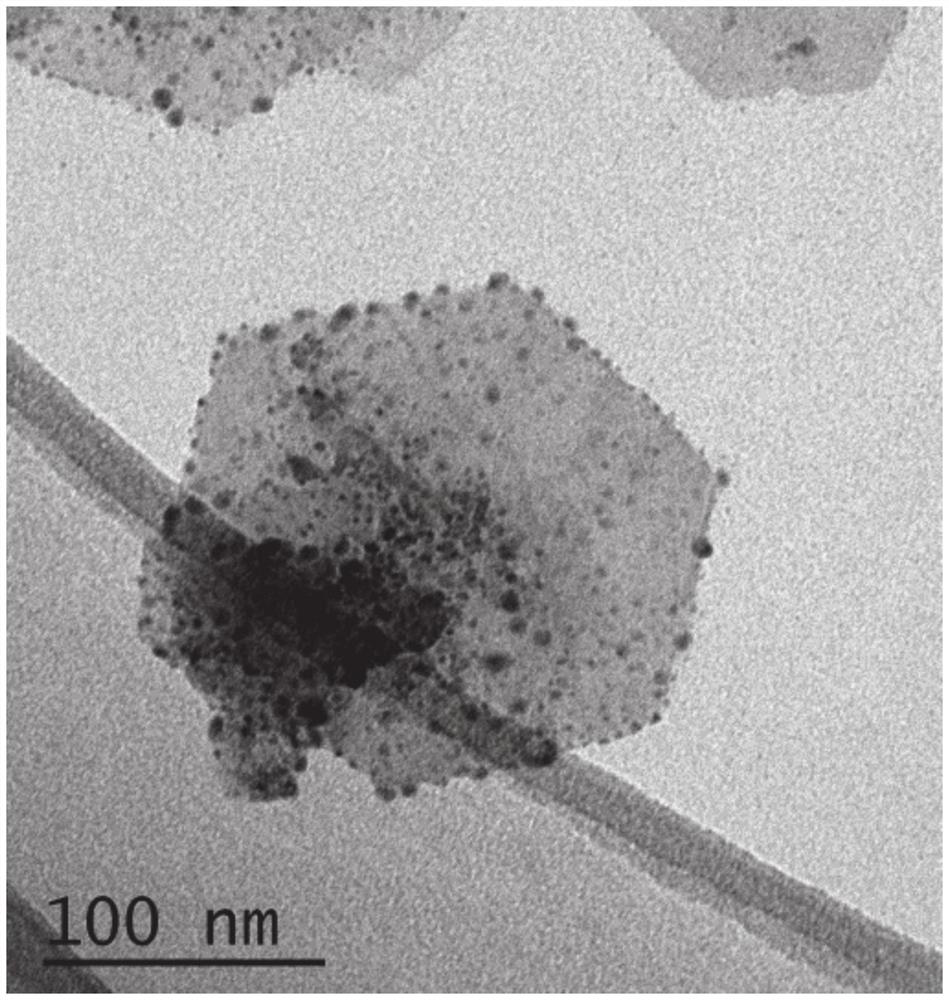

[0073] (3) Immerse the cleaned nickel foam into the reaction solution, seal it in a stainless steel autoclave for solvothermal reaction at 120°C for 12h, cool it out, wash it with ultrapure water and ethanol, and place it in an oven at 60°C in the air Dry for 12h. at 5mA / cm 2 The Ag@NiFe-LDH / NF highly stable oxygen evolution catalyst was obtained by electroplating for 5 min at the c...

Embodiment 2

[0077] (1) Cut commercial nickel foam into strips of 1cm × 3cm, at 2mol·L -1 Ultrasonic treatment in the hydrochloric acid solution for 3min, then ultrasonic cleaning three times in deionized water and absolute ethanol respectively, and natural drying in the air for standby use, and the anode matrix NiFe-LDH / NF was prepared according to the same method as in Example 1.

[0078] (2) The parameter of magnetron sputtering is set to 300W, the sputtering time is 10s, and the vacuum degree of the vacuum chamber is adjusted to 0.3-5pa.

[0079] (3) Hang the dried NiFe-LDH / NF electrode sheet into a vacuum chamber and perform magnetron sputtering according to the parameters in (2) to obtain a highly stable Ag@NiFe-LDH / NF high stability oxygen evolution anode , the size of the sputtered silver particles is determined by the sputtering time, and the growth rate of the silver particles is controlled by the sputtering power, wherein the sputtering power is 300W and the sputtering 10s is th...

Embodiment 3

[0083] (1) Cut commercial nickel foam into strips of 1cm × 3cm, at 2mol·L -1 Ultrasonic treatment for 3 min in hydrochloric acid solution, then ultrasonic cleaning for three times in deionized water and absolute ethanol respectively, and natural drying in air for use.

[0084] (2) Dissolve 130.8 mg of nickel nitrate hexahydrate, 60.6 mg of ferric nitrate nonahydrate and 300 mg of urea in 36 mL of deionized water to prepare a solvothermal reaction solution containing nickel and iron, and transfer it to a 50 mL polytetrafluoroethylene material reaction tank middle.

[0085] (3) Immerse the cleaned nickel foam into the reaction solution, seal it in a stainless steel autoclave for solvothermal reaction at 120°C for 12h, cool it out, wash it with ultrapure water and ethanol, and place it in an oven at 60°C in the air Dry for 12h. The above electrodes were then soaked in a commercial chemical immersion silver plating solution for 10 minutes to obtain a highly stable Ag@NiFe-LDH / NF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com