Thermal spraying long-acting corrosion-resistant protective coating on surface of grounding electrode and preparation method of thermal spraying long-acting corrosion-resistant protective coating

A technology of protective coating and surface spraying, applied in the direction of coating, metal material coating process, melt spraying, etc., to achieve the effect of low cost, improved wettability, and improved long-term corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

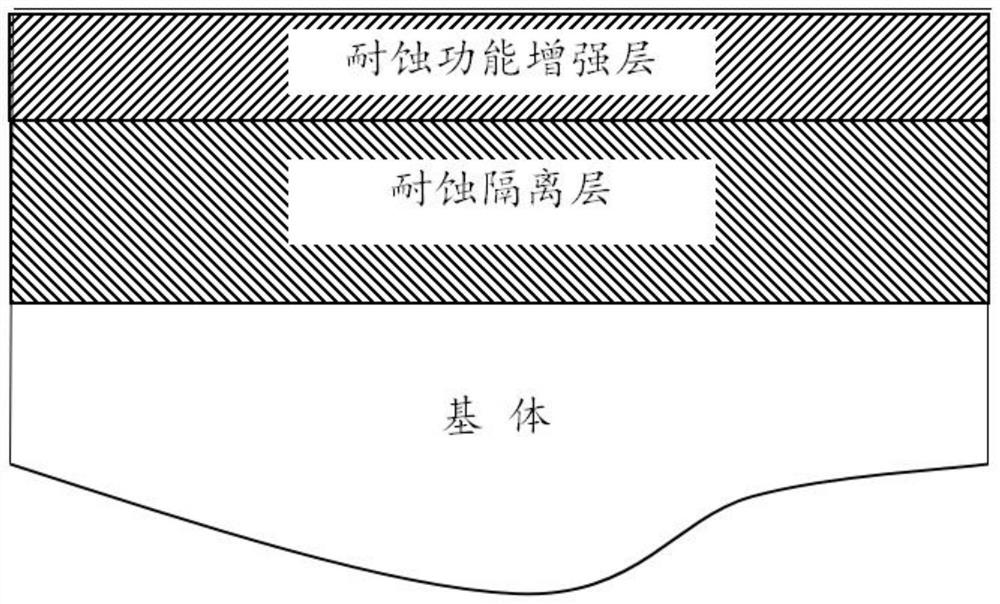

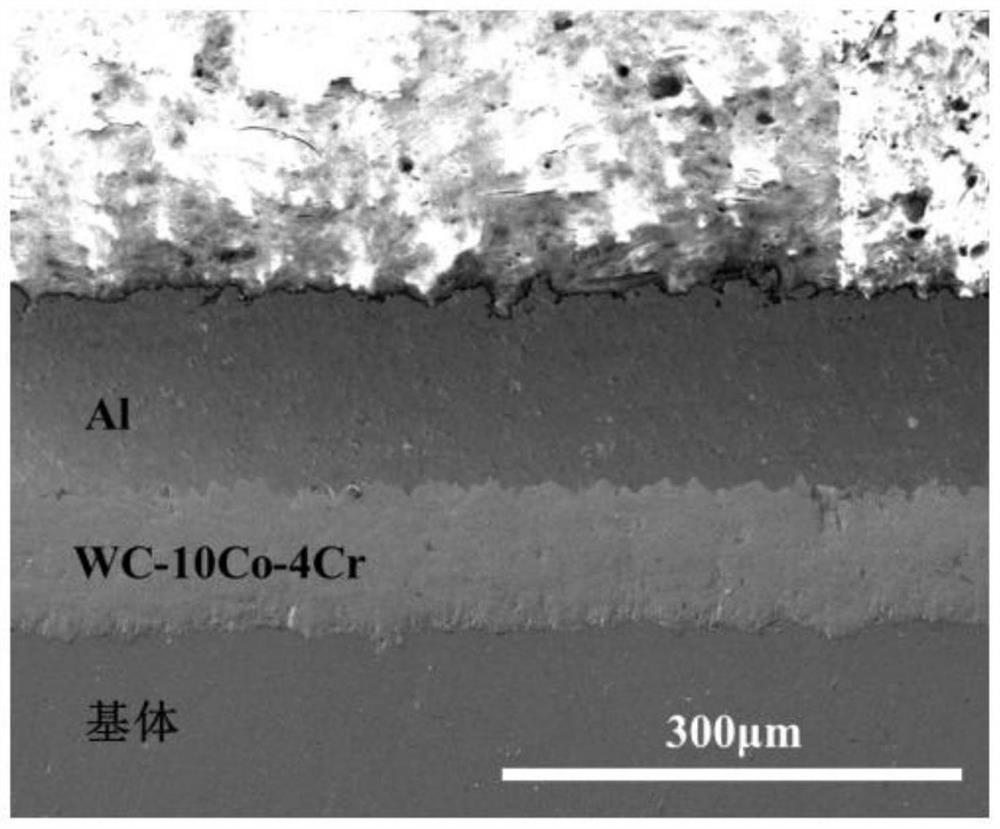

[0021] Embodiment 1: In this embodiment, a thermal sprayed long-term corrosion-resistant protective coating on the surface of the ground electrode is composed of a corrosion-resistant isolation layer and a corrosion-resistant function enhancement layer, wherein the corrosion-resistant isolation layer has a thickness of 50-250 μm, and the corrosion-resistant function The thickness of the reinforcement layer is 100-300 μm.

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the thickness of the corrosion-resistant isolation layer is 100-200 μm; the thickness of the corrosion-resistant function enhancement layer is 150-250 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the corrosion-resistant isolation layer is composed of 1-5% rare earth material, 1-10% carbon material, 20-80% by mass percentage It is composed of cermet material and the balance of nickel-based metal material; wherein, the rare earth material is one or two of cerium oxide and yttrium oxide mixed in any ratio, and the particle size is 5-40nm; the carbon material is conductive graphite, conductive acetylene carbon , One or more of carbon nanotubes are mixed in any ratio, the particle size is 5-20nm, the size of carbon nanotubes is 1-5nm in diameter and 5-20μm in length; the cermet material is Cr 3 C 2 -Ni, WC-Co, WC-Co-Cr, Cr 3 C 2 -NiCr, Cr 3 C 2 - One or more of CoNiCrAlY and WC-FeCrAl are mixed in any ratio, and the particle size is 30-80 μm; the nickel-based metal is one or more of stainless steel, nickel-chromium alloy, and Ni60, and the particle size is mixed in any ratio. 20 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com