Microgroove group heat dissipation device with porous medium material and heat dissipation method

A technology of porous medium and heat dissipation device, which is applied in the direction of cooling/ventilation/heating transformation, semiconductor/solid-state device parts, semiconductor devices, etc., which can solve the problems of inability to contact the phase-change working medium in the radiator, and improve the liquid filling rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

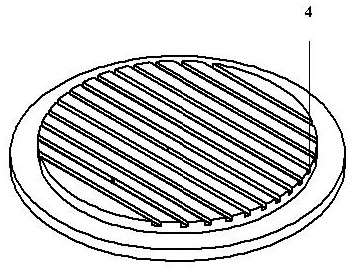

[0031] In the micro-groove group radiator with porous dielectric material in this embodiment, the main radiator 1 is provided with a vacuum cavity 5 and filled with a certain amount of phase change working medium. The fin group 2 is installed on the main body radiator 1 by a plurality of fin monomers at equal intervals. The porous medium material 3 is a ceramic porous material or a foamed metal material and is closely attached around the heat sink 4 of the micro-groove group. The micro-groove group heat sink 4 is arranged at the bottom of the main body heat sink 1 and is connected to the bottom of the vacuum chamber 5 . The heat source is tightly fixed on the bottom surface of the heat sink 4 of the micro-groove group through thermal interface materials such as thermally conductive silicone grease or thermally conductive silicone pad.

[0032] like figure 1 As shown, the main radiator 1 is a sunflower radiator, with an outer diameter of 20-200mm and a height of 20-200mm, and...

Embodiment 2

[0034] like figure 2 As shown in the figure, a micro-groove group radiator with porous dielectric material in this embodiment is further improved on the basis of Embodiment 1. The shape of the porous dielectric material 3 is a circular ring, and the size is an inner diameter of 15~190mm. , The outer diameter is 20~200mm, the height is 1~5mm, and the material is ceramic or foam metal, which is used to absorb the phase change working medium. Ceramic porous materials have the advantages of low price, long service life, light weight, and anti-oxidation; foam metal has the advantages of controllable porosity, stable structure, and high temperature resistance. Both materials can be in close contact with the heat sink 4 of the microgroove group.

Embodiment 3

[0036] like Figure 3-5As shown, a micro-groove group heat sink with porous dielectric material in this embodiment is further improved on the basis of Embodiment 2, in order to make the porous dielectric material 3 and the micro-groove group heat sink 4 in close contact. The heat sink 4 of the micro-groove group is designed to be concentric cylinders with different diameters, and the radius of the upper cylinder is smaller than the radius of the lower cylinder. Among them, the outer diameter of the upper cylinder is 15~190mm, the height is 1~5mm, the outer diameter of the lower cylinder is 20~200mm, and the height is 1~15mm, and the upper surface has evenly distributed micro-channels, including N, of which N≥10, the arrangement density More than 2 pieces / cm, the cross section of the micro channel is rectangular, triangular, trapezoidal or other irregular shapes, and the dimensions are: groove width 20~5000µm, groove depth 20~5000µm, groove spacing 20~5000µm. The assembly of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com