Separator having excellent thermal conductivity and electrochemical device using same

A diaphragm and oxide film technology, applied in the field of electrochemical devices, can solve problems such as the limitation of fire possibility, achieve excellent heat dissipation characteristics, improve thermal shrinkage rate, and uniform temperature difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106]

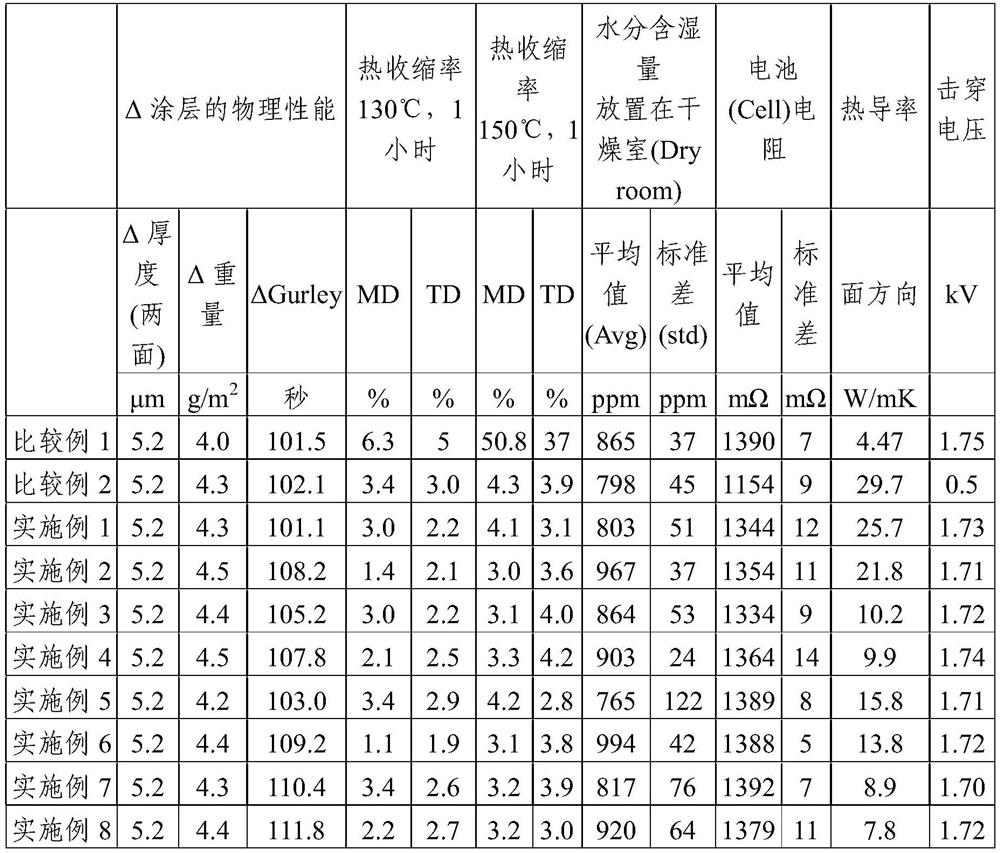

[0107] An aqueous dispersion of 30 wt % of solid content of core-shell silicon particles having a solid content of 30 wt % dissolved and dispersed with 4 wt % of water-soluble polyvinyl alcohol and 96 wt % of core-shell silicon particles having an average particle diameter of 1 μm and an oxide film shell layer of 10 nm was prepared. The aqueous dispersion was ball milled for 3 minutes to prepare an aqueous dispersion slurry. The prepared slurry was coated on both sides of a 11 μm polyethylene separator (51% porosity) by slot extrusion coating and dried sufficiently, each side was 2.6 μm in terms of the thickness of the active layer , with a total thickness of 5.2 μm. The physical properties, thermal shrinkage rate, thermal conductivity and moisture content of the coatings of the produced separators were measured and reported in Table 1.

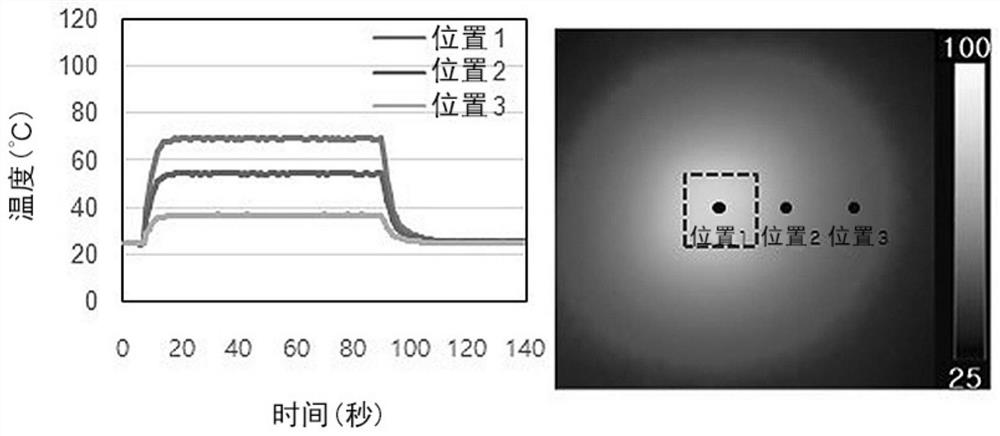

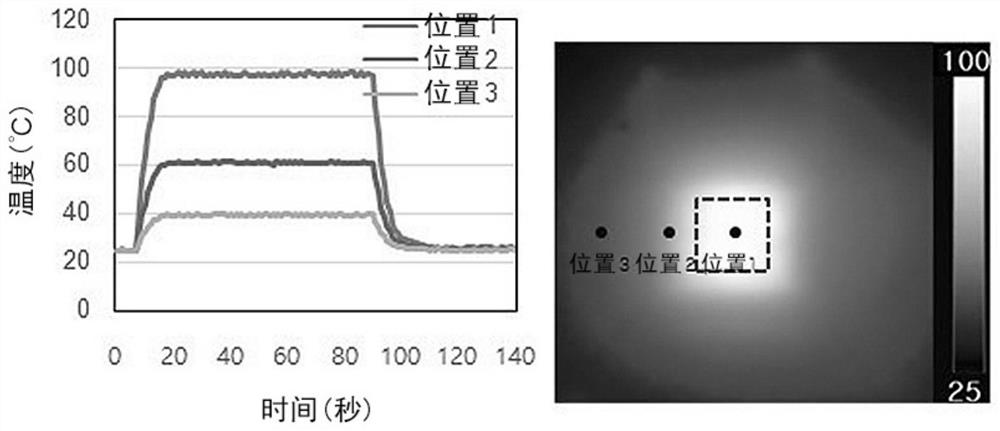

[0108] In addition, as a result of evaluating the heat dissipation performance, in the case of Example 1 ( figure 1 ), the resu...

Embodiment 2

[0119] The same method was carried out except that 0.5 μm core-shell silicon particles were used in Example 1, and the results are shown in Table 1.

Embodiment 3

[0121] The same method was carried out except that 50% by weight of 1.0 μm core-shell silicon particles and 50% by weight of 0.7 μm boehmite particles were used in Example 1 instead of 1.0 μm core-shell silicon particles, and the The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com