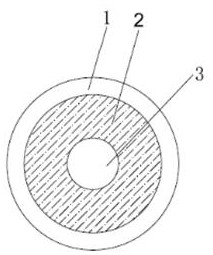

Armored signal cable for self-powered neutron detector and preparation method thereof

A neutron detector and signal cable technology, which is applied in nuclear power generation, insulating cables, insulating conductors/cables, etc., can solve the problems of the length and dimensional accuracy of a single branch of insulation resistance, and the surface roughness cannot meet the needs of use. Easy to control, improve coaxiality, avoid contamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A preparation method of an armored signal cable for a self-sufficient neutron detector, comprising the following steps:

[0056] S1. The casing should be an Inconel 600 alloy casing with a diameter of φ8mm, a wall thickness of 2mm and a length of 5m. Conductor signal core wire selection wire diameter is φ2.3mm Inconel 600 alloy wire. The surface of the casing and the conductor signal core wire is required to be smooth, free from cracks, burrs and other defects. The casing and conductor signal cores are cleaned and pretreated by a combination of chemical and physical methods. First, pickling (concentration of 5% HF and 15% HNO is used) 3 Mixture of HF:HNO 3 The volume ratio is 2:8), alkaline washing and neutralization (5% NaOH solution concentration) are carried out after the acid washing, and then rinsed with high-pressure deionized water. Scrub the conductor signal core wire until the gauze is no obvious black.

[0057] The composition and proportion of Inconel 600...

Embodiment 2

[0083] A preparation method of an armored signal cable for a self-sufficient neutron detector, comprising the following steps:

[0084] S1. Select an Inconel 600 alloy casing with a diameter of φ10mm, a wall thickness of 2mm and a length of 5m. Conductor signal core wire selection wire diameter is φ2.5mm Inconel 600 alloy wire. The surface of the casing and the conductor signal core wire is required to be smooth, free from cracks, burrs and other defects. The casing and conductor signal cores are cleaned and pretreated by a combination of chemical and physical methods. First, pickling (concentration of 5% HF and 15% HNO is used) 3 Mixture of HF:HNO 3 The volume ratio is 2:8), alkaline washing and neutralization (5% NaOH solution concentration) are carried out after the acid washing, and then rinsed with high-pressure deionized water. Scrub the conductor signal core wire until the gauze is no obvious black. The preparation method of Inconel 600 alloy sleeve and Inconel 600 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com