Ferro-cobalt bimetallic phosphating nano-particles with nitrogen-doped carbon as substrate and preparation method and application of ferro-cobalt bimetallic phosphating nano-particles

A bimetallic nano, nitrogen-doped carbon technology, applied in the field of electrocatalytic materials, can solve the problems of low conductivity, complex parameters, complex preparation of multi-component phosphides, etc., achieving low cost, wide sources, good cycle stability and electrical The effect of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

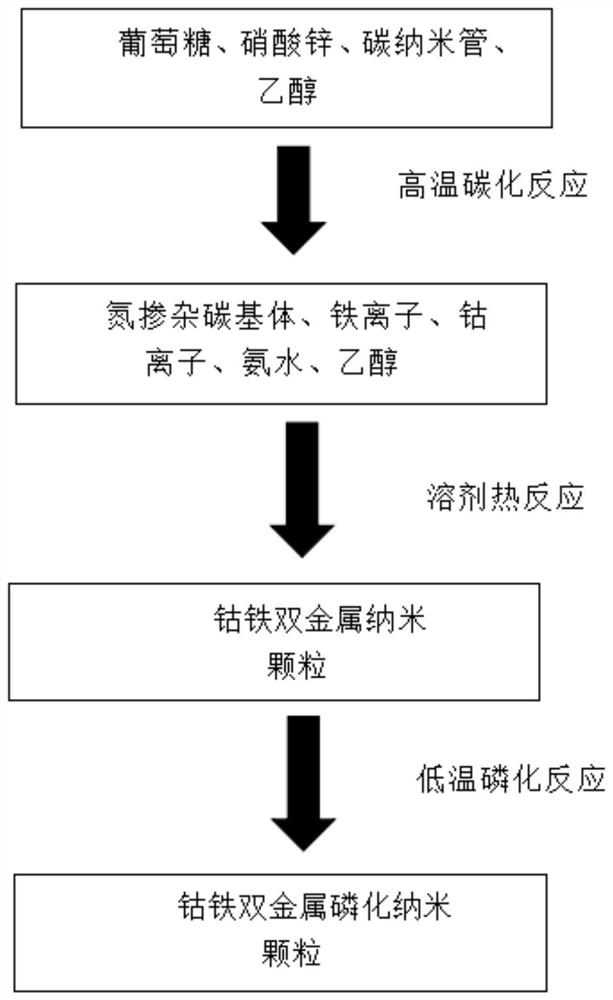

[0026] This embodiment is as follows figure 1 The shown method prepares cobalt-iron bimetallic phosphating nanoparticles based on nitrogen-doped carbon, and the steps are as follows:

[0027] Step 1. Preparation of nitrogen-doped carbon matrix: 1.5g of zinc nitrate hexahydrate, 0.5g of glucose, and 1mg / ml of carbon nanotubes were dissolved in 50ml of ethanol, the solution was sonicated for 5 minutes, stirred for half an hour, and the tube type under the protection of argon Heated to 200°C in a furnace with a heating rate of 5°C min -1 , the holding time was 2 hours, and the obtained black solid was soaked in hydrochloric acid, washed with ethanol and purified water by suction filtration, and dried overnight to obtain a nitrogen-doped carbon matrix.

[0028] Step 2. Preparation of cobalt-iron bimetallic nanoparticles: using 40mg nitrogen-doped carbon matrix and 0.4ml with a concentration of 0.6molL -1 of cobalt acetate, 0.4ml concentration is 0.6mol L -1 ferric acetate, 1ml ...

Embodiment 2

[0031] The present embodiment prepares cobalt-iron bimetallic phosphating nanoparticles, and the steps are as follows:

[0032] Step 1. Preparation of cobalt-iron bimetallic nanoparticles: use 0.4ml with a concentration of 0.6mol L -1 of cobalt acetate, 0.4ml concentration is 0.6mol L -1 ferric acetate, 1ml of ammonia water, 48ml of ethanol, etc. to form a solution, stirred overnight, and then put into a high-pressure reactor for hydrothermal reaction. Ethanol was filtered, washed and dried overnight to obtain cobalt-iron bimetallic nanoparticles.

[0033] Step 2. Preparation of cobalt-iron bimetallic phosphide nanoparticles: 40 mg of cobalt-iron bimetallic phosphide nanoparticles and 400 mg of sodium hypophosphite were heated and kept in a tube furnace under argon protection, the reaction temperature was 350 °C, and the heating rate was 4 °C min -1 , the holding time is 2 hours, and cobalt-iron bimetallic phosphating nanoparticles are finally obtained.

Embodiment 3

[0035] This embodiment is as follows figure 1 The shown method prepares cobalt-iron bimetallic phosphating nanoparticles based on nitrogen-doped carbon, and the steps are as follows:

[0036] Step 1. Preparation of nitrogen-doped carbon matrix: 1.5g of zinc nitrate hexahydrate, 0.5g of glucose, and 1mg / ml of carbon nanotubes were dissolved in 50ml of ethanol, the solution was sonicated for 5 minutes, stirred for half an hour, and the tube type under the protection of argon Heated to 200°C in a furnace with a heating rate of 5°C min -1 , the holding time was 2 hours, and the obtained black solid was soaked in hydrochloric acid, washed with ethanol and purified water by suction filtration, and dried overnight to obtain a nitrogen-doped carbon matrix.

[0037] Step 2. Preparation of cobalt-iron bimetallic nanoparticles: using 40mg nitrogen-doped carbon matrix and 0.2ml concentration of 0.6molL -1 of cobalt acetate, 0.6ml concentration is 0.6mol L -1 Ferric acetate, 1ml ammonia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com