Waste sulfuric acid recovery treatment method

A disposal method, waste sulfuric acid technology, applied in the direction of separation method, chemical recovery, chemical instruments and methods, etc., can solve the problems of endangering human health and living environment, polluting the environment, waste of sulfuric acid resources, etc., to reduce chroma and reduce impurities Ion content, effect of reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

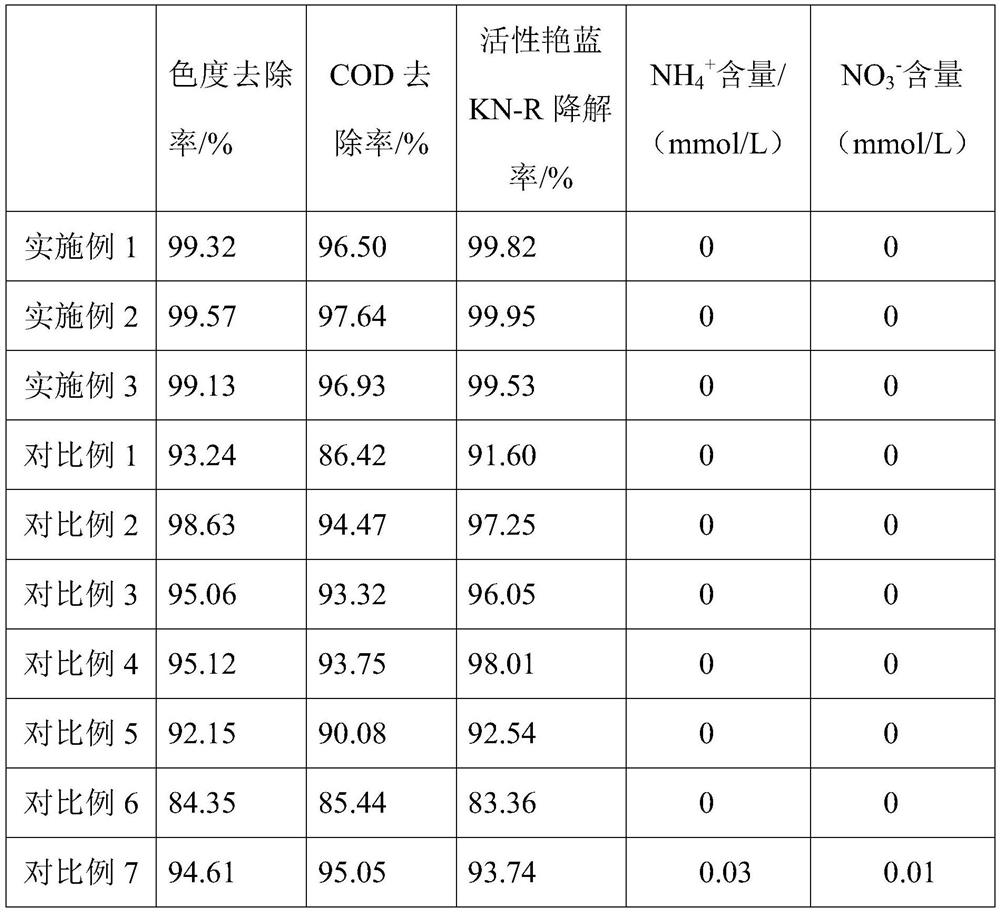

Embodiment 1

[0025] A method for recycling and disposing of waste sulfuric acid:

[0026] To the anthraquinone dye-reactive brilliant blue KN-R produced in the production process, the chromaticity is 5820 times, the COD is 7553mg / L, the pH is 1, after diluting the waste sulfuric acid with water to pH 3, add the catalyst, the catalyst dosage is 1g / L, under the irradiation of 250W metal halide lamp, 300W ultrasonic wave and stirring for 10h, the filtrate was obtained after filtration, the D201 resin was added to the ion exchange column, rinsed with deionized water for 40min, and then used 10 times the mass of D201 resin 1mol / L NaOH solution and 1mol / L HCl solution were rinsed alternately for 50min, and finally the resin was rinsed with deionized water to neutrality, then placed in 1mol / L sodium EDTA solution for 100min immersion, air-dried at room temperature and added to the filtrate , the resin dosage is 10g / L, after 25h of adsorption, filtration to obtain recycled sulfuric acid, which i...

Embodiment 2

[0030] A method for recycling and disposing of waste sulfuric acid:

[0031] To the anthraquinone dye-reactive brilliant blue KN-R produced in the production process, the chromaticity is 5820 times, the COD is 7553mg / L, the pH is 1, and the waste sulfuric acid is diluted with water to pH 5, and then the catalyst is added, and the catalyst dosage is 1g / L, under the irradiation of 250W metal halide lamp, 300W ultrasonic and stirring for 20h, the filtrate was obtained after filtration, the D201 resin was added to the ion exchange column, rinsed with deionized water for 50min, and then used 2mol of 10 times the mass of D201 resin. / L NaOH solution and 2mol / L HCl solution were alternately rinsed for 50min, and finally the resin was rinsed with deionized water to neutrality, and then placed in 1mol / L sodium EDTA solution for 120min immersion, air-dried at room temperature and added to the filtrate , the resin dosage is 10g / L, after 25h of adsorption, filtration to obtain recycled s...

Embodiment 3

[0035] A method for recycling and disposing of waste sulfuric acid:

[0036]To anthraquinone dye-reactive brilliant blue KN-R produced in the production process, the chromaticity is 5820 times, the COD is 7553mg / L, the pH is 1, and the waste sulfuric acid is diluted with water to pH 4, then the catalyst is added, and the catalyst dosage is 0.5g / L, under the irradiation of 250W metal halide lamp, 300W ultrasonic wave and stirring for 5h, the filtrate was obtained after filtration, the D201 resin was added to the ion exchange column, rinsed with deionized water for 30min, and then used 8 times the mass of D201 resin. 1mol / L NaOH solution and 1mol / L HCl solution were alternately rinsed for 30min, and finally the resin was rinsed with deionized water to neutrality, then immersed in 1mol / L sodium EDTA solution for 90min, and the filtrate was added after air-drying at room temperature. , the resin dosage is 5g / L, after 20h of adsorption, filtration to obtain recovered sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com