Polybenzoquinone polymer and preparation method thereof

A technology of polymers and quinones, which is applied in the field of multi-polyquinone polymers and their preparation, can solve the problems of poor dimensional stability of sodium lauryl sulfate, uneven size of PAQR hollow spheres, and serious volatilization of monomers. Achieve uniform appearance, high product purity, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The specific steps of the preparation method include:

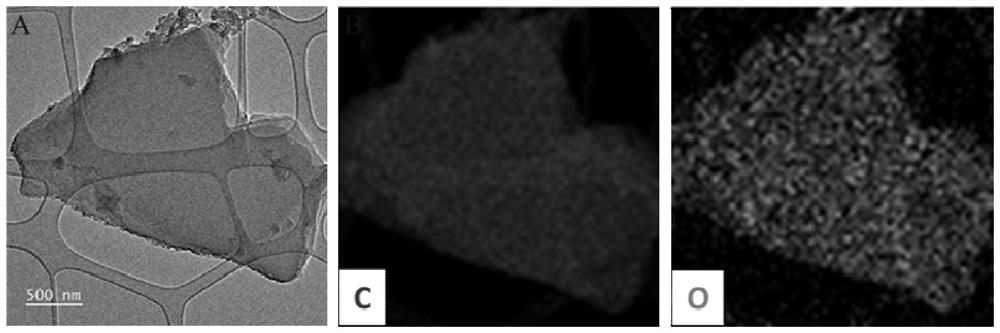

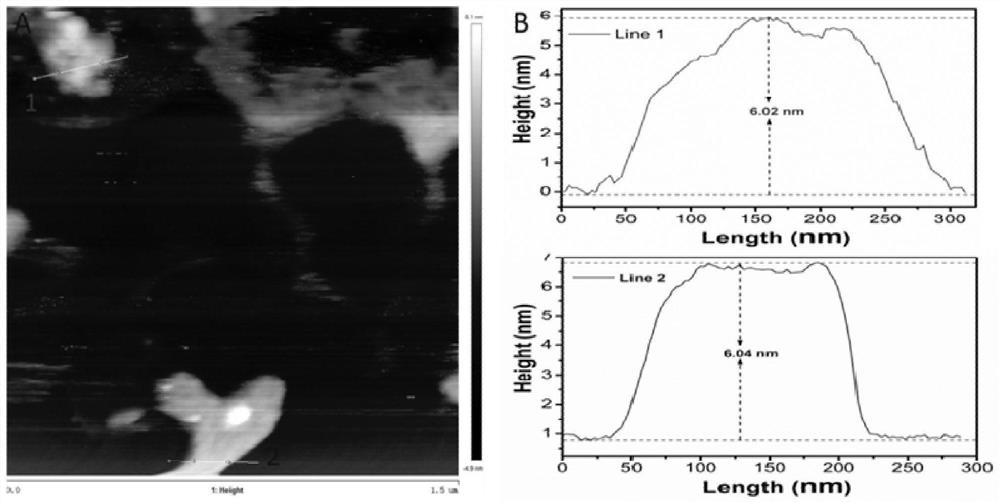

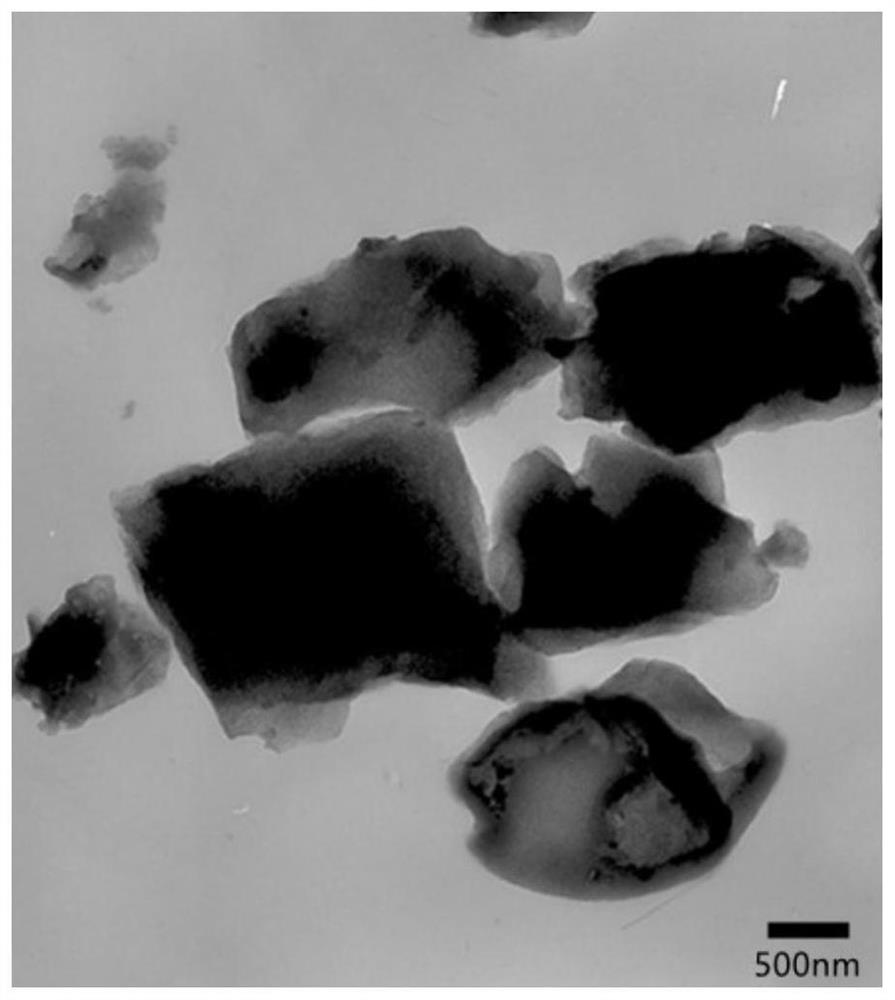

[0030] The modified montmorillonite with Lewis acid as the intercalating agent is selected as the template, and the modified montmorillonite, fused-ring aromatic hydrocarbon and acid anhydride are added to the first solvent and mixed evenly; after ultrasonic treatment, suction filtration and drying are performed to obtain the first solid; One solid is heated up and reacted, and after the reaction is completed, it is cooled to room temperature to obtain a second solid; the second solid is purified to obtain the polyquinone polymer.

[0031] As an optional embodiment, the modified montmorillonite uses Lewis acid as an intercalating agent, and the Lewis acid can be selected from quaternary ammonium salt, ZnCl 2 , AlCl 3 , FeCl 3 one of the others. The montmorillonite intercalated with Lewis acid can play the role of template and catalyst at the same time, which makes the reaction efficiency higher and the reaction ...

Embodiment 1

[0041] A preparation method of polyquinone polymer comprises the following steps:

[0042] 1 mol of anthraquinone, 1 mol of pyromellitic dianhydride and 1 mol of organically modified montmorillonite (the interlayer intercalating agent is a quaternary ammonium salt) are placed in 300 mol of acetone and mixed uniformly.

[0043] Ultrasonic for 24h, suction filtration and drying to obtain the first solid.

[0044]The dried first solid was transferred to a muffle furnace, and the heating program was set as follows: the room temperature was raised to 100°C, and kept for 1 hour; 100°C was raised to 150°C, and the temperature was kept for 1 hour; 150°C was raised to 200°C, and the temperature was kept for 1 hour. 1 hour; 200°C to 250°C, hold for 1 hour; 250°C to 300°C, hold for 1 hour; 300°C to 310°C, hold for 20 hours; cooling to room temperature to obtain a second solid.

[0045] The powder of the obtained second solid was placed in a Soxhlet extractor, and 200ml of hydrochloric a...

Embodiment 2

[0049] A preparation method of polyquinone polymer comprises the following steps:

[0050] 1mol of anthracene, 1mol of pyromellitic dianhydride and 1mol of organically modified montmorillonite (the interlayer intercalator is ZnCl) 2 ) in 300 mol of acetone and mixed evenly.

[0051] Ultrasonic for 24 h, suction filtration and drying to obtain the first solid.

[0052] The dried first solid was transferred to a muffle furnace, and the heating program was set as follows: the room temperature was raised to 100°C, and kept for 1 hour; 100°C was raised to 150°C, and the temperature was kept for 1 hour; 150°C was raised to 200°C, and the temperature was kept for 1 hour. 1 hour; 200°C to 250°C, hold for 1 hour; 250°C to 300°C, hold for 1 hour; 300°C to 310°C, hold for 20 hours; cooling to room temperature to obtain a second solid.

[0053] The powder of the obtained second solid was placed in a Soxhlet extractor, and 200ml of hydrochloric acid, 500ml of water, 300ml of ethanol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com