Stretchable layered thermal camouflage material and preparation method thereof

A layered, carbon material electrode technology, used in camouflage devices, protective equipment, lamination devices, etc., can solve the problems of poor tensile cycle stability, easy deformation and damage of thermal camouflage materials, and inability to perform functions stably, and achieve deformability. Good, structurally strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

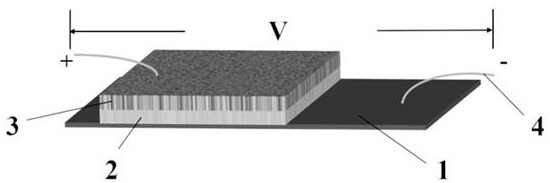

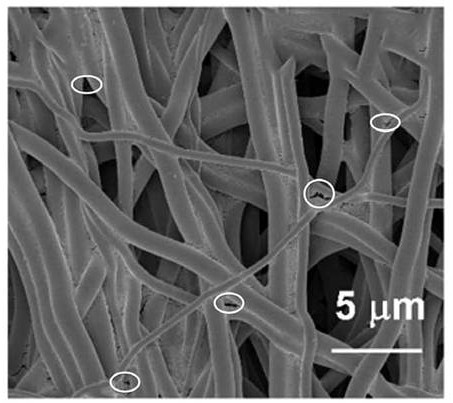

[0053] A stretchable layered thermal camouflage material of the present invention, the structure is as follows figure 1 As shown, it includes a carbon material electrode layer 1, an ion conductive gel layer 2 and an electrochromic functional layer 3 that are arranged in sequence from bottom to top. Spinning porous thermoplastic polyurethane fiber membrane layer, ion conductive gel layer 2 is a mixed dry membrane layer of water-based polyurethane and ionic liquid, electrochromic functional layer 3 is doped (surface coating and internal penetration) poly 3, 4- Electrospun porous thermoplastic polyurethane fiber membrane layers of ethylenedioxythiophene-polystyrenesulfonic acid. When applying, such as figure 1 As shown, copper wires 4 can be welded on the surfaces of the electrochromic functional layer 3 and the carbon material electrode layer 1 respectively, which are used as positive and negative electrodes respectively, and the output voltage of the source meter is used at bo...

Embodiment 2

[0067] A stretchable layered thermal camouflage material of the present invention includes a carbon material electrode layer 1, an ion conductive gel layer 2 and an electrochromic functional layer 3 that are sequentially stacked from bottom to top. The carbon material electrode layer 1 is: Electrospun porous thermoplastic polyurethane fiber membrane layer doped with carbon black particles and carboxylated carbon nanotubes, ion conductive gel layer 2 is a mixed dry membrane layer of aqueous polyurethane and ionic liquid, and electrochromic functional layer 3 is a surface coating The electrospun porous thermoplastic polyurethane fiber membrane layer is covered and infiltrated with poly3,4-ethylenedioxythiophene-polystyrenesulfonic acid.

[0068] In this embodiment, the thickness of the stretchable layered thermal camouflage material is 220 μm, the thickness of the carbon material electrode layer 1 is 60 μm, the thickness of the ion conductive gel layer 2 is 100 μm, and the thickn...

Embodiment 3

[0075] A stretchable layered thermal camouflage material of the present invention includes a carbon material electrode layer 1, an ion conductive gel layer 2 and an electrochromic functional layer 3 that are sequentially stacked from bottom to top. The carbon material electrode layer 1 is: Electrospinning porous thermoplastic polyurethane fiber membrane layer doped with carbon black particles and carboxylated carbon nanotubes, ion conductive gel layer 2 is a mixed dry membrane layer of aqueous polyurethane and ionic liquid, electrochromic functional layer 3 is a surface coating Electrospun porous thermoplastic polyurethane fiber membrane covered and infiltrated with poly3,4-ethylenedioxythiophene-polystyrenesulfonic acid.

[0076] In this embodiment, the thickness of the stretchable layered thermal camouflage material is 220 μm, the thickness of the carbon material electrode layer 1 is 60 μm, the thickness of the ion conductive gel layer 2 is 100 μm, and the thickness of the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com