Patella fracture threading device with threading, tightening and knotting functions

A technology for patella fracture and wire-passing device, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems that manual operation cannot guarantee the degree of tightening, the process is cumbersome and time-consuming, and the threading process is difficult, etc., and achieves real-time accuracy. Master the tightening force, the tightening effect is good, and the speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

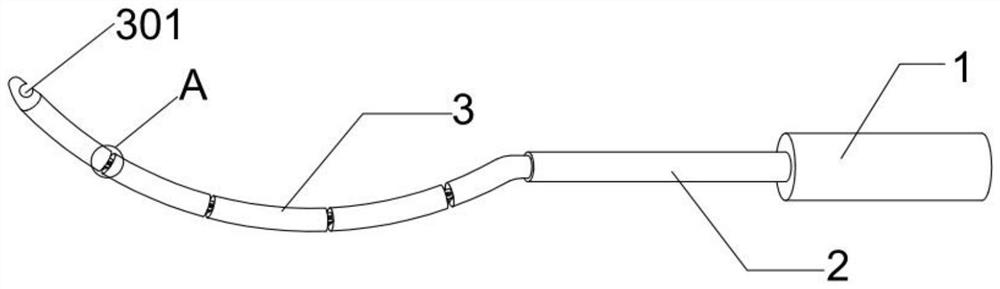

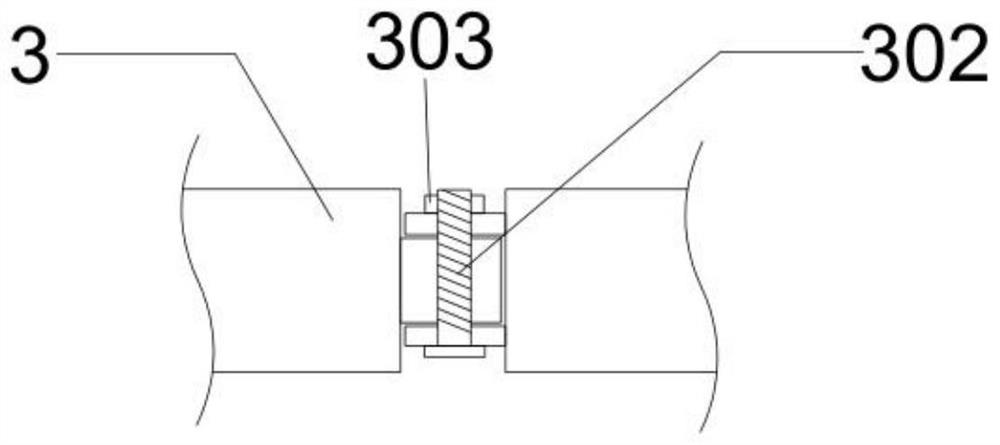

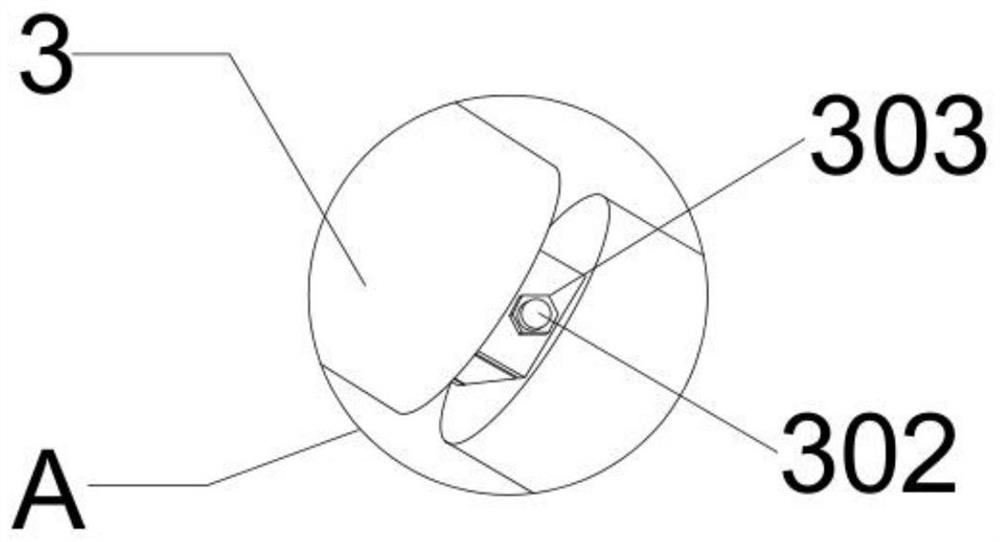

[0044] see Figure 1 to Figure 10 As shown in the figure, a patella fracture wire passing device with functions of threading and tightening and knotting includes: a handle 1, a connecting rod 2, an arc rod 3, a transition section 4, a micro motor 5, an outer cylinder 6, and a rotating shaft rod 7. Injection pipe 8;

[0045] The left end of the handle 1 is fixedly connected to the connecting rod 2, and the left end of the connecting rod 2 is detachably connected to the arc-segment rod 3, wherein the arc-segment rod 3 is divided into several sections, and each section can be hingedly connected, and the rightmost section is the one The arc segment rod 3 is detachably connected to the left end of the above-mentioned connecting rod 2; the left end of the connecting rod 2 can also be detachably connected to the automatic knotting part, wherein the automatic knotting part is composed of the transition section 4, the micromotor 5, the outer cylinder 6, the rotating shaft rod 7 , the ...

Embodiment 2

[0053] Based on Embodiment 1, for the inner fixed wire knot, the collet 12 can also be used to cooperate with the wire knot fixing part of the plastic wire clip 16. The specific structure is that the wire knot fixing part is driven by the collet 12, the outer rod 13, and the collet. The rod 14, the spring 15, and the plastic wire clip 16 are formed; the outer cylinder 6 is provided with a collet transmission rod channel, the channel opening is connected to the outer rod 13, the outer rod 13 is hollow, and the collet transmission rod 14 passes through the collet transmission rod channel and Inside the outer rod 13, there are two collets 12, which are respectively connected to the outer rod 13 and the collet transmission rod 14; A spring 15 is connected between the end and the bottom end of the transmission rod channel of the collet; the plastic wire clip 16 is detachably placed between the two collets 12 .

Embodiment 3

[0055] Based on Embodiment 1, when the rotating shaft rod 7 drives the wire hook 701 to rotate, the torque can be monitored in real time by the torque sensor 9 of the micromotor 5, and the torque is converted into a digital signal by the D / A converter 11 after being processed by the built-in program of the microprocessor 10 for display. , it is convenient to accurately grasp the tightening force of the internal fixation wire or internal fixation wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com