Brake shoe and preparation method thereof

A brake shoe and mass fraction technology, applied in the field of wear-resistant materials, can solve the problems of difficulty in meeting the use requirements of brake shoes, weakened friction, poor wear resistance, etc., and achieves difficult deformation, small friction coefficient changes, and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

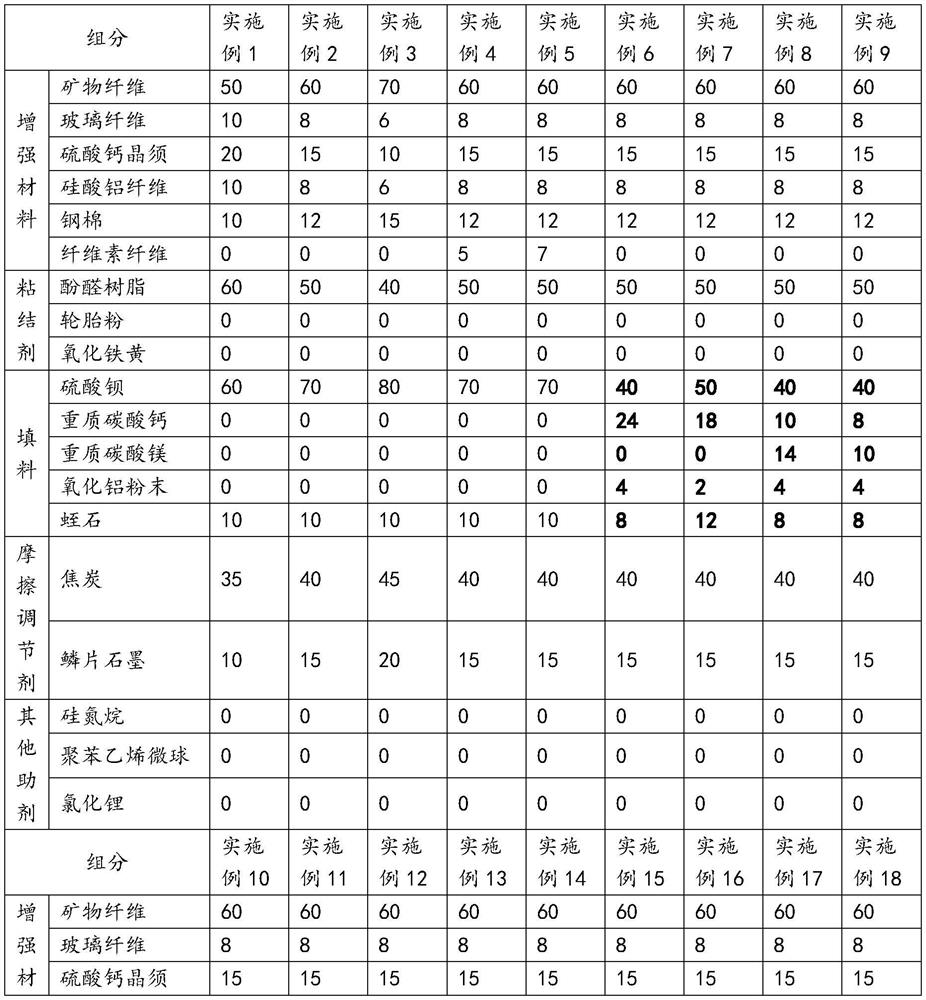

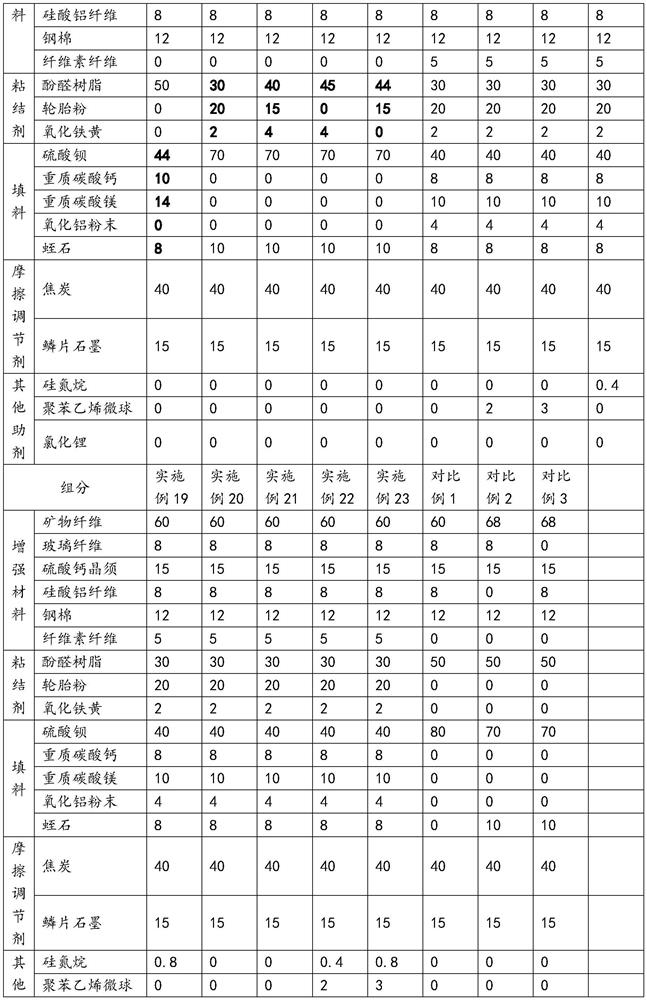

Examples

Embodiment 2

[0060] Embodiment 24, the difference with embodiment 2 is that the preparation method is as follows:

[0061] 1. Mix the above materials and dehydrate under vacuum at 60°C for 10min;

[0062] S2. The dehydrated material is hot-pressed at 100°C, and the pressure-holding time is 250s;

[0063] S3. The product after hot pressing is heat treated, and the heat treatment temperature is increased from 100°C to 185°C within 12h;

[0064] S4. The heat-treated product is subjected to groove grinding, electrostatic spraying, assembling accessories, coding, plastic sealing, and packaging to obtain brake shoes.

[0065] In the above embodiments, the phenolic resins are all octylphenolic vulcanized resins.

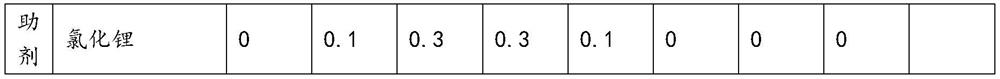

Embodiment 25

[0066] Example 25 is different from Example 22 in that the octylphenolic vulcanized resin is replaced by a brominated p-tert-octylphenolic vulcanized resin.

[0067] For the above examples and comparative examples, with reference to "GB 5763-2008 automotive brake linings", the normal temperature friction coefficient, high temperature friction coefficient, secondary decay (93~288 ℃) friction coefficient minimum value, secondary friction coefficient of the above-mentioned brake shoe were measured The minimum value of the coefficient of friction (149-93°C) and the wear amount at 300°C were recovered (149-93°C).

[0068] The experimental results of Examples 1 to 25 and Comparative Examples 1 to 3 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com