Noctilucent water-permeable multifunctional brick capable of catalytically degrading automobile exhaust and manufacturing method of noctilucent water-permeable multifunctional brick

A technology of automobile exhaust and catalytic degradation, applied in chemical instruments and methods, ceramic products, inorganic chemistry, etc., can solve the problems of low utilization rate of clean recycling, environmental pollution by automobile exhaust, large power consumption of urban lighting, etc., to increase convenience The effect of improving the efficiency of cleaning and recycling, reducing the energy consumption of brick making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

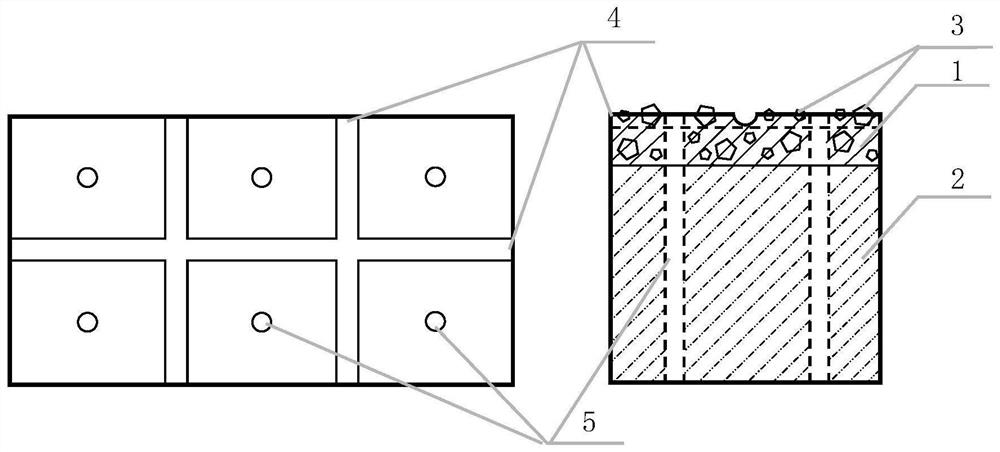

Image

Examples

preparation example Construction

[0041] The preparation method of the luminous water-permeable multifunctional brick capable of catalytically degrading automobile exhaust gas comprises the following steps:

[0042] S1: Preparation of coconut shell activated carbon: take coconut shell carbonized material after carbonization at 550-650 ℃ for 50-70min as raw material, pulverize and sieve to a particle size of 160-200mm, and use KOH solution with a mass fraction of 40-60% As an activator, after the two are mixed to carry out the activation reaction, pyrolyzed at 350 to 500 ° C for 110 to 130 min to obtain coconut shell activated carbon, and the specific weight proportioning range is: based on the coconut shell carbonized material of 100 parts by weight, KOH The solution is 50-80 parts by weight;

[0043] S2: Preparation of modified nanoscale titanium dioxide: Mix the fully substituted N-trialkylpolysaccharide quaternary ammonium salt and lactic acid, add 4 to 6 times the total weight of water, and heat and stir a...

Embodiment 1

[0052] 1) Preparation of coconut shell activated carbon: take the coconut shell carbonized material after carbonization at 600 ° C for 60min as the raw material, pulverize and sieve to a particle size of 180mm, and use a KOH solution with a mass fraction of 50% as an activator, the two are mixed to carry out. After the activation reaction, pyrolysis 120min at 450 DEG C to obtain coconut shell activated carbon, and the specific weight proportioning range is: based on the coconut shell carbonization material of 100 parts by weight, the KOH solution is 60 parts by weight; Potassium has a strong electron donating ability. When it diffuses into the micropores, it will react with carbon-containing substances to form complex salts, which decompose into potassium and carbon at high temperature. The specific surface area of the prepared coconut shell activated carbon is 2809m 2 / g, the total pore volume is 1.798cm 3 / g.

[0053] 2) Preparation of modified nano-scale titanium dioxid...

Embodiment 2

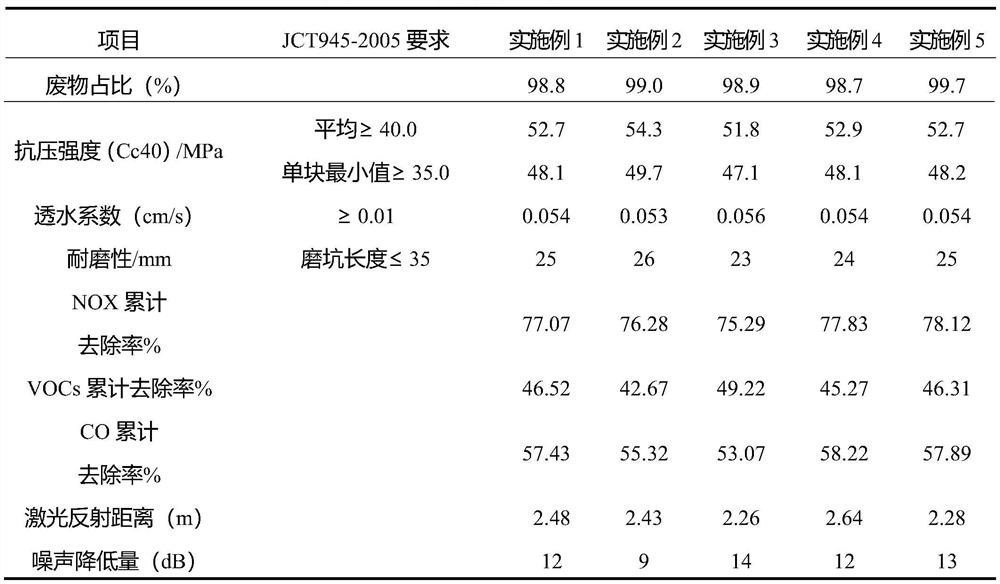

[0061] The same procedure and raw materials as in Example 1 were used. The modulus of water glass is 1.0, and the permeable base layer is configured. The specific quality is: 720g of tailings waste rock, 90g of industrial by-product gypsum, and 80g of geopolymer. The covering layer is configured, and the specific mass is: 180g of tailings waste rock, 22.5g of industrial by-product gypsum, 13.5g of waste glass particles in 20g of geopolymer, and 6.3g of coconut shell activated carbon loaded with modified nanoscale titanium dioxide. Press molding, demoulding, and curing waste bricks. The performance indicators of the test all meet the requirements of the permeable brick standard for the building materials industry of the People's Republic of China (JCT945-2005), and have the functions of catalytic degradation of automobile exhaust, night lighting, noise reduction and other functions (see Table 1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com