Bamboo composite pipe-steel pipe internal-external constraint concrete composite structure

A technology for constraining concrete and composite structures, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of reduced structural bearing capacity, consumption of mineral resources, and non-recyclability, etc., to improve deformation capacity, reduce environmental pollution, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

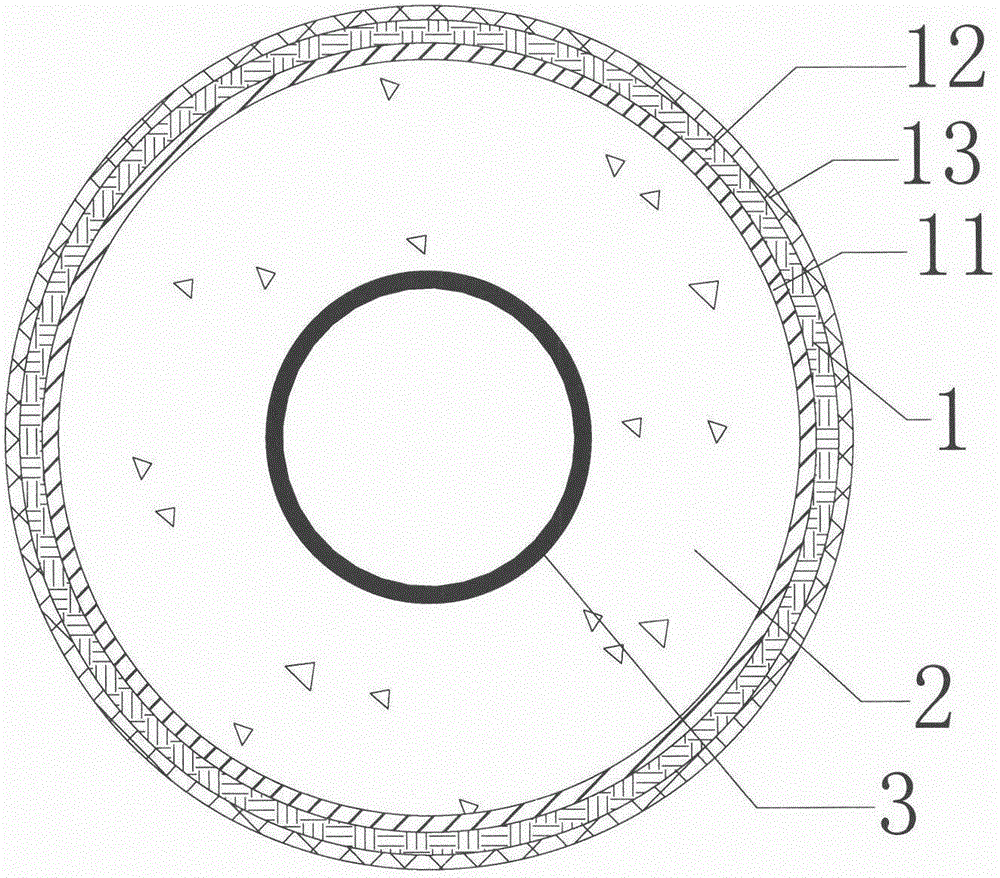

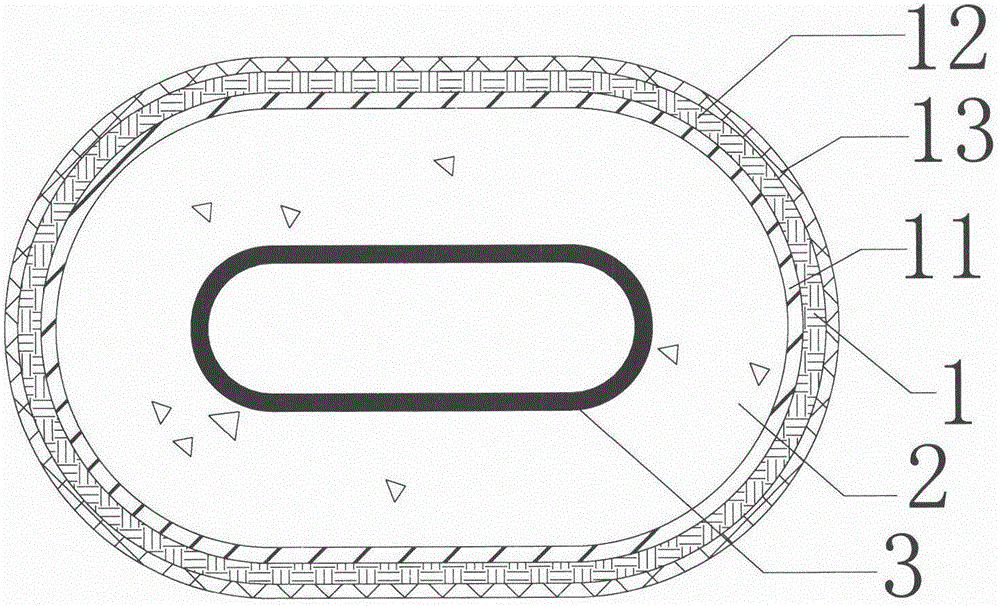

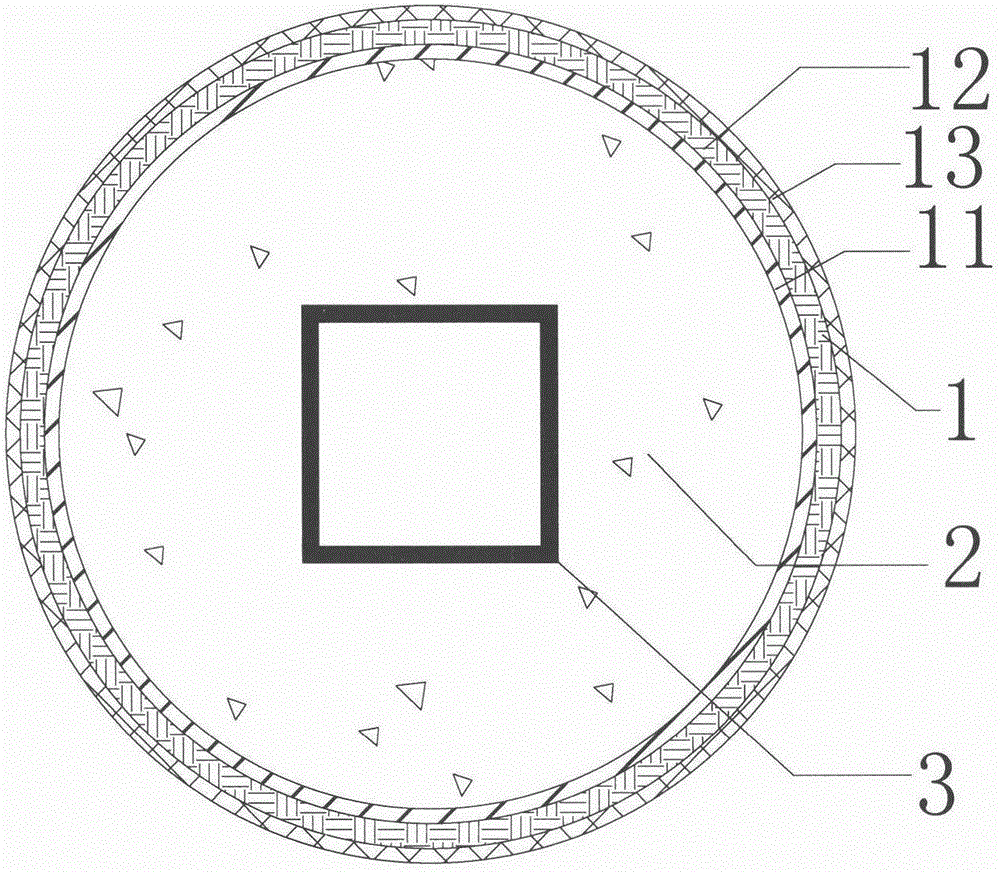

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The invention provides a bamboo composite pipe-steel pipe inner and outer constrained concrete composite structure, which is characterized in that its cross section is composed of bamboo composite pipe 1, interlayer concrete 2 and inner steel pipe 3 from outside to inside, and the bamboo composite pipe 1 is sequentially from inside to outside Including an isolation layer 11, a bamboo fiber reinforced composite layer 12 and an outer protective layer 13, wherein the isolation layer 11 is continuously and uniformly wound and solidified by bamboo fiber mat, glass fiber mat, basalt fiber mat or bamboo fiber non-woven fabric impregnated with resin glue, Bamboo fiber-reinforced composite layer 12 is formed by continuous and uniform winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com