Water-gas separation technology for production and injection in same well through electric submersible pump

A technology of submersible electric pump and same well production and injection, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., which can solve the problems of gas well production damage, environmental pollution, non-compliance, etc., and increase the gas production of gas wells , the effect of good technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

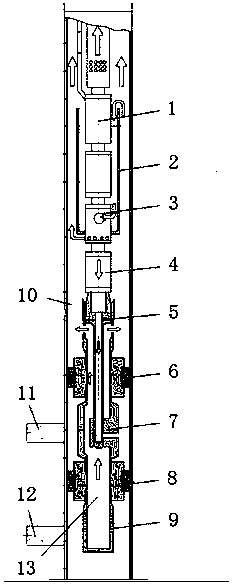

[0024] refer to figure 1 , a water-gas separation technology using electric submersible pumps in the same well production and injection, including electric submersible pump unit 1, gas-liquid separation guide device 2, gas-liquid diversion device 7, gas-liquid channel 10 and packer layered sealing system 13 , the packer layered sealing system 13 is composed of a first packer 6, a second packer 8 and a screen 9, and the first packer 6 is located above the second packer 8, and the gas-liquid splitting device 7 is located between the first packer 6 and the second divider 8, the bottom of the sealing cannula 5 is inserted into the inner cavity of the gas-liquid separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com