MEMS device and manufacturing method thereof

A manufacturing method and device technology, applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of large packaging volume and low integration of MEMS devices, achieve fast signal transmission speed, and improve device performance , to achieve the effect of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 of the present invention provides a method for fabricating a MEMS device, comprising the following steps:

[0038]S01: Provide a logic chip, the logic chip includes a substrate and a CMOS circuit on the substrate, a first structural layer is formed on the logic chip, and a first isolation trench is formed on the first structural layer;

[0039] S02: Provide a bulk acoustic wave filter, the bulk acoustic wave filter includes: a carrier substrate, a support layer formed on the surface of the carrier substrate, and a piezoelectric material that surrounds a second cavity with the carrier substrate and the support layer A laminated structure, the piezoelectric laminated structure includes a second electrode, a piezoelectric layer, and a first electrode stacked in sequence;

[0040] S03: The BAW filter is bonded on the first structural layer on the logic chip, so that the first isolation groove is sandwiched between the logic chip and the BAW filter to form a fir...

Embodiment 2

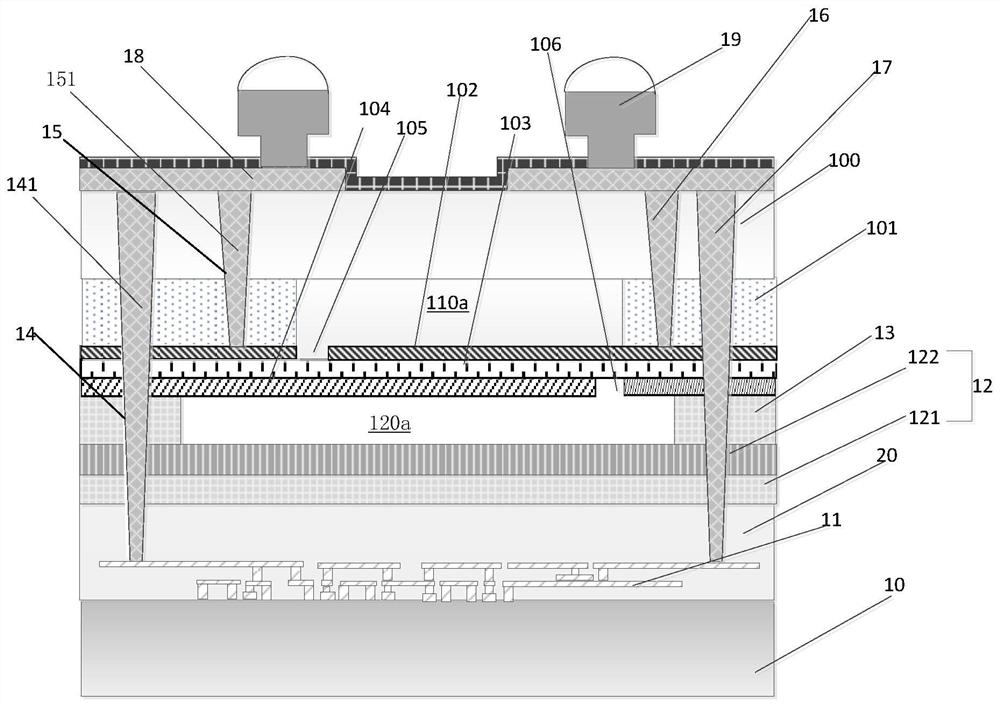

[0094] This embodiment 2 provides a MEMS device, figure 1 A schematic structural diagram of a MEMS device of the second embodiment is shown, please refer to figure 1 , the MEMS device includes:

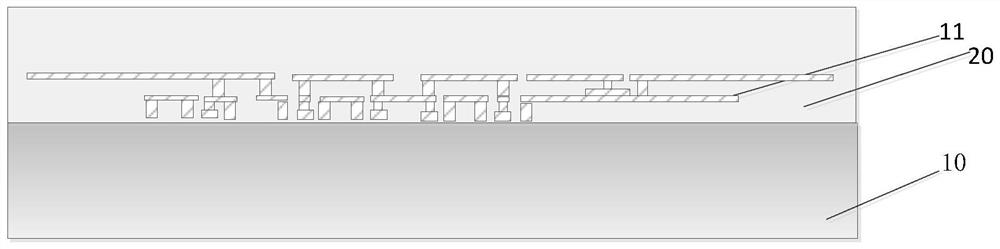

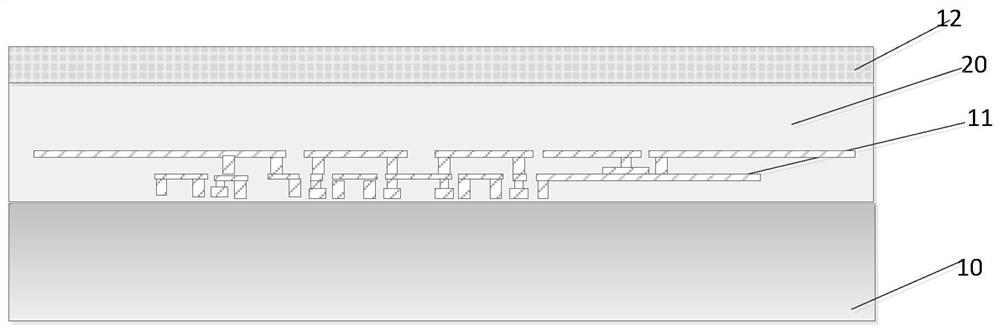

[0095] a logic chip, the logic chip includes a CMOS circuit 11;

[0096] a first structural layer 13, the first structural layer 13 is located above the logic chip;

[0097] A bulk acoustic wave filter, the bulk acoustic wave filter is located above the first structural layer, and there is a bonding interface between the bulk acoustic wave filter and the first structural layer; the bulk acoustic wave filter includes a bearing lining the bottom 100, the acoustic reflection structure on the surface of the carrier substrate 100, and the piezoelectric laminated structure on the acoustic reflection structure;

[0098] The first structure layer 13 has a first cavity 120a, and the effective resonance region of the piezoelectric laminated structure is located in the first cavity 120a.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com