A kind of flexible sensor manufacturing process and flexible sensor

A flexible sensor and manufacturing process technology, applied in the field of sensors, can solve the problems of difficult mass production of flexible sensors, a large number of leads, and an uncompact structure, and achieve the effects of improving yield and production efficiency, superior performance, and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

[0034] The embodiment of the present invention provides a flexible sensor manufacturing process, referring to Figure 2-Figure 11 ,include:

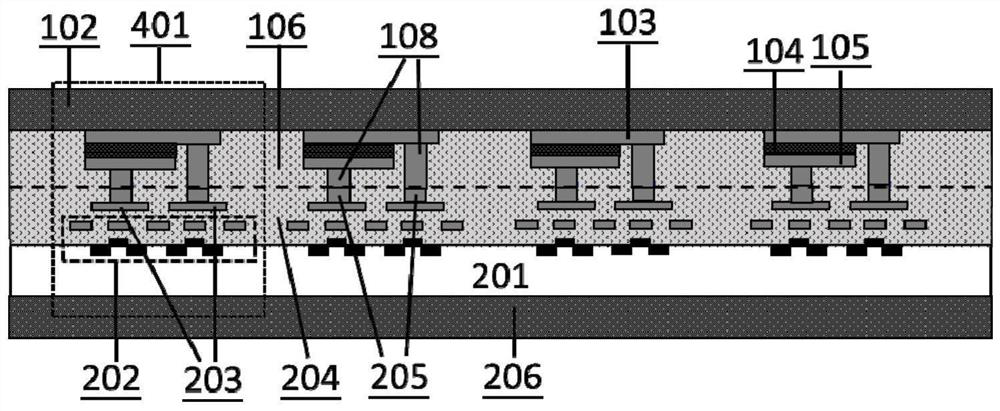

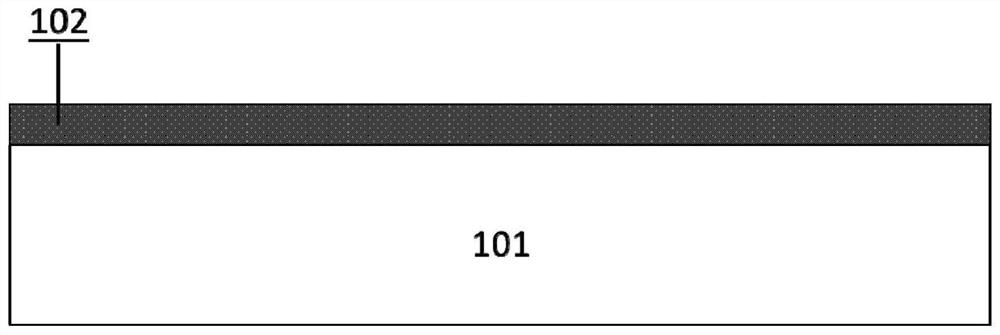

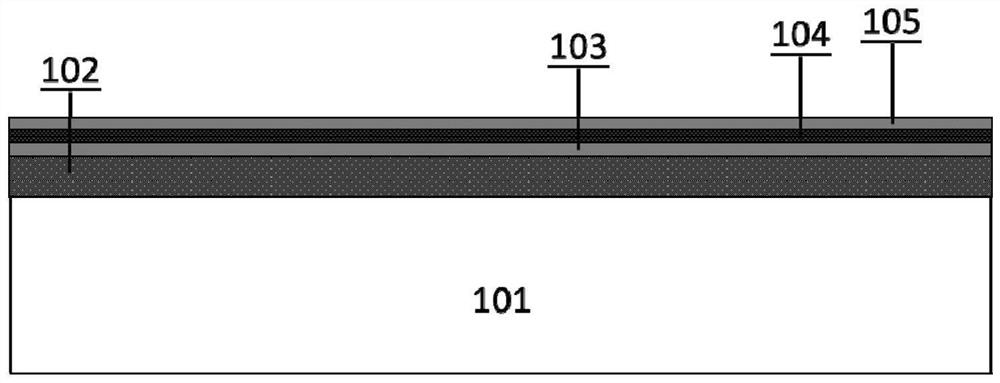

[0035] A first silicon wafer 101 is provided, and a first flexible substrate layer 102 is fabricated on the first silicon wafer 101 by deposition or spin coating, for details, refer to figure 2 As shown; on the first flexible substrate layer 102 of the first silicon wafer 101, the first electrode layer film 103, the sensitive layer film 104 and the second electrode layer film 105 are sequentially produced by deposition or spin coating, forming Sensor thin film layer, refer to image 3 As shown; the first patterning process and the second patterning process are sequentially performed on the sensor film layer to form a number of sensing prototypes distributed at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com