Coke oven heating system and method adopting oxygen-enriched combustion

An oxygen-enriched combustion and heating method technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of unusable producer gas, low-quality gas, high combustion temperature, heat loss, etc., and save construction and operation costs , strong radiation ability and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

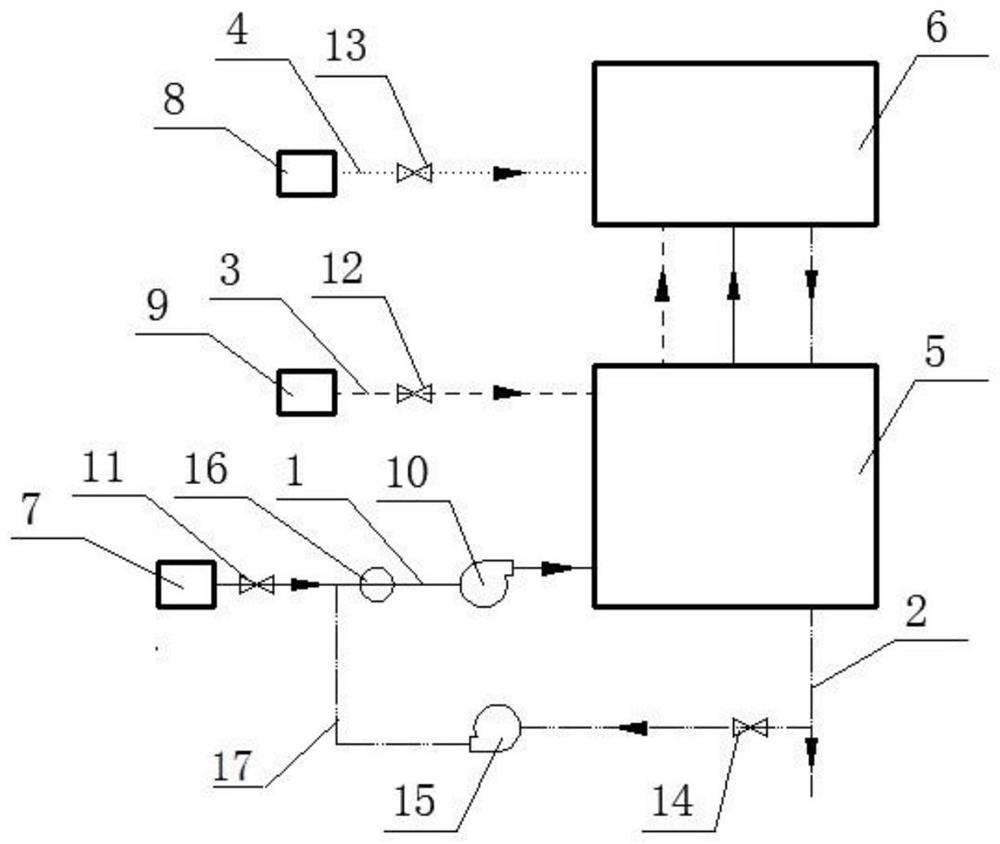

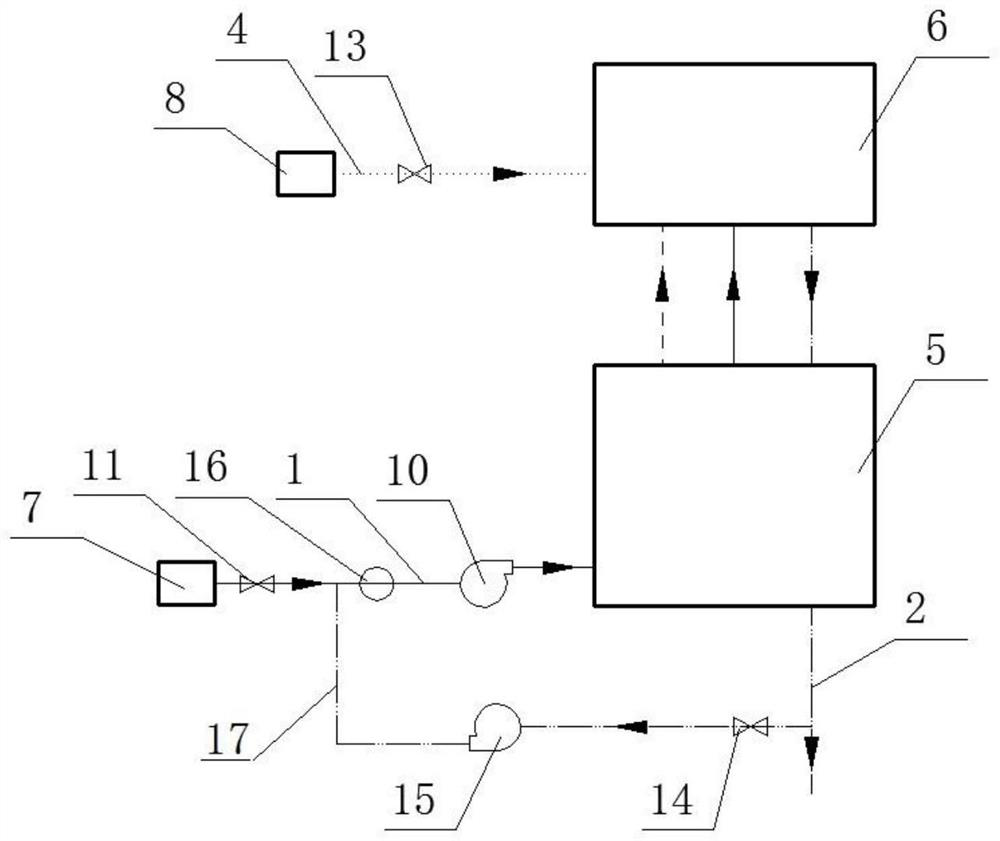

[0052] A single-heat coke oven is heated by coke oven gas, and the calorific value of coke oven gas is 17500kJ / Nm 3 , The combustion-supporting gas used in the original heating system is air. Due to the high heat consumption of coking, the presence of coke in the upper part of the coke cake, and the emission of nitrogen oxides exceeding the standard, the existing heating system is modified.

[0053] like figure 2 As shown, oxygen-enriched gas pipeline and exhaust gas return pipeline 17 are added to the reformed coke oven heating system, and a return exhaust gas regulating valve 14 and a return exhaust gas fan 15 are equipped.

[0054] When the modified coke oven heating system works, the oxygen delivered from the oxygen pipe network 7 is mixed with the returned combustion exhaust gas to form an oxygen-rich gas with an oxygen content of 50%, and the oxygen-rich gas enters the heat storage through the oxygen-rich gas pipe 1. Chamber 5, after being preheated by regenerator 5, t...

Embodiment 2

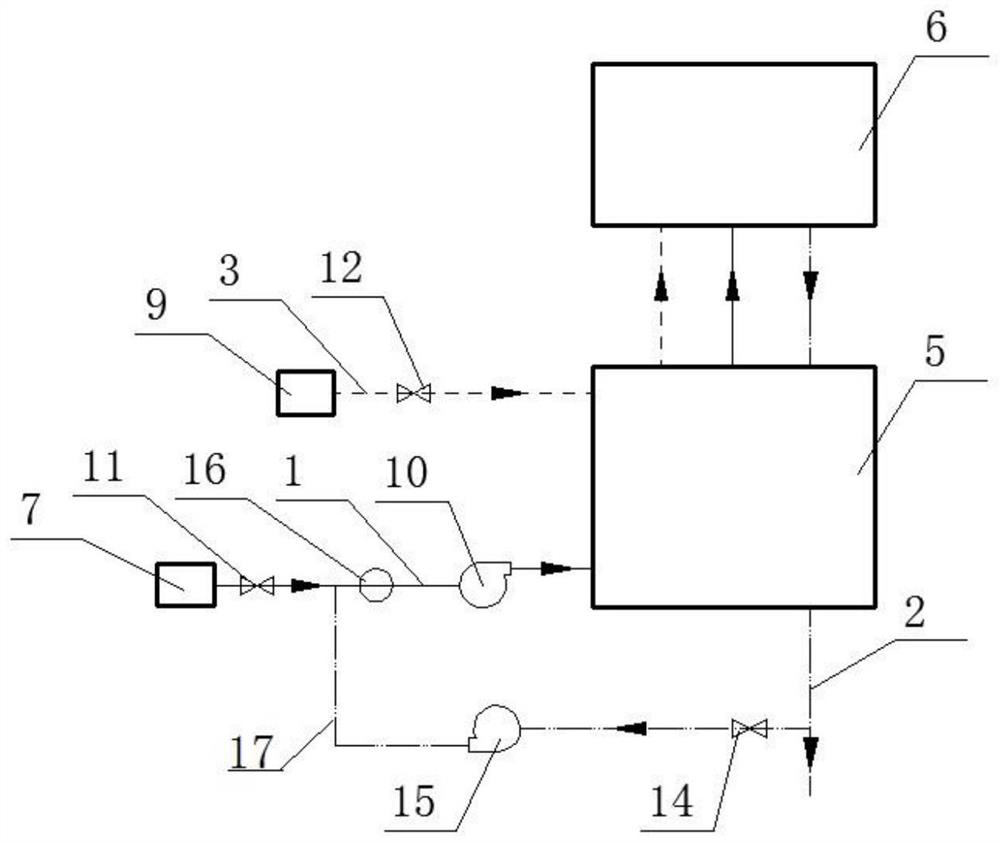

[0059] In a new coking plant, it is planned to use the purge gas from the methanol synthesis in the plant as the heating gas source for the coke oven, and use the coke oven gas with high calorific value for other purposes. The calorific value of the purge gas is 9800kJ / Nm 3 . Due to the high hydrogen content and low methane and carbon monoxide content in the purge gas, its calorific value is lower than that of coke oven gas. At the same time, due to the high hydrogen content in the purge gas, there may be a risk of explosion after preheating in the regenerator. Therefore, the purge gas needs to enter the combustion chamber directly through the rich gas pipeline. When air with an oxygen concentration of 21% meets, it is easy to defire in the combustion chamber and cannot be stably burned. That is, using the existing coke oven heating system may cause the purge gas to fail to achieve stable combustion in the combustion chamber.

[0060] The heating system of the new coke oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com