A kind of improved coking coal humidity control method and equipment

A technology for coking coal and humidity control, which is used in coke ovens, petroleum industries, etc., can solve the problems of coal dust leaking into the surrounding environment and the waste gas system, and the high moisture content of fine coal powder, so as to improve moisture consistency and improve Coke quality and yield, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

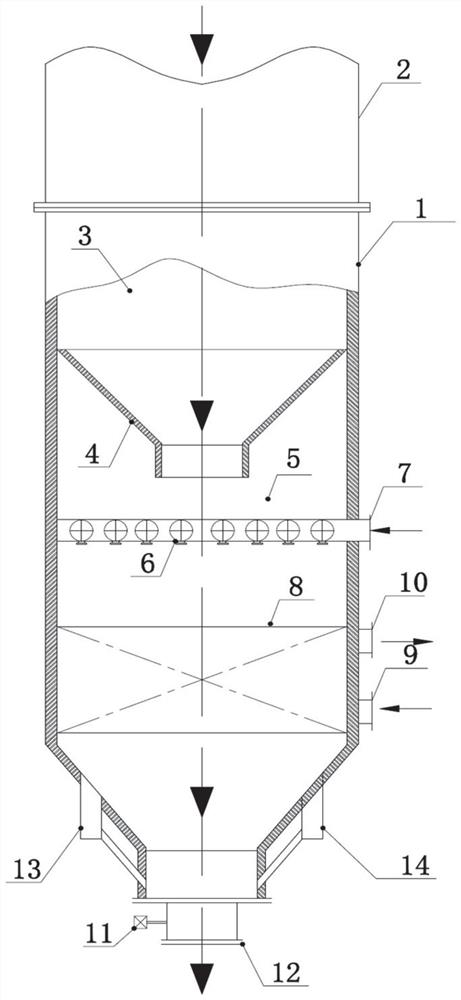

Embodiment 1

[0066] Wet coking coal with an average moisture content of 12% used in top-loading coke ovens, in which the largest coal particle size is not greater than 7mm, and the weight ratio of fine coal powder with a particle size below 0.2mm is 33%, and the particle size is 0.2mm~ The weight ratio of 3.0mm granular coal is 52%, and the minimum distillation temperature of the volatile fraction is 230°C. It is required to have an average moisture content of about 8% after the coal humidity control treatment, and the moisture in the coking coal The deviation of the distribution consistency is less than 2%, and the processing capacity of a single set of coal humidity control device is 80 tons / hour.

[0067] The characteristic of wet coking coal that requires humidity control is that the average moisture content of wet coking coal is 12%, among which the moisture in fine coal powder is the highest, and its moisture content is about 14%, including external moisture and internal moisture, due...

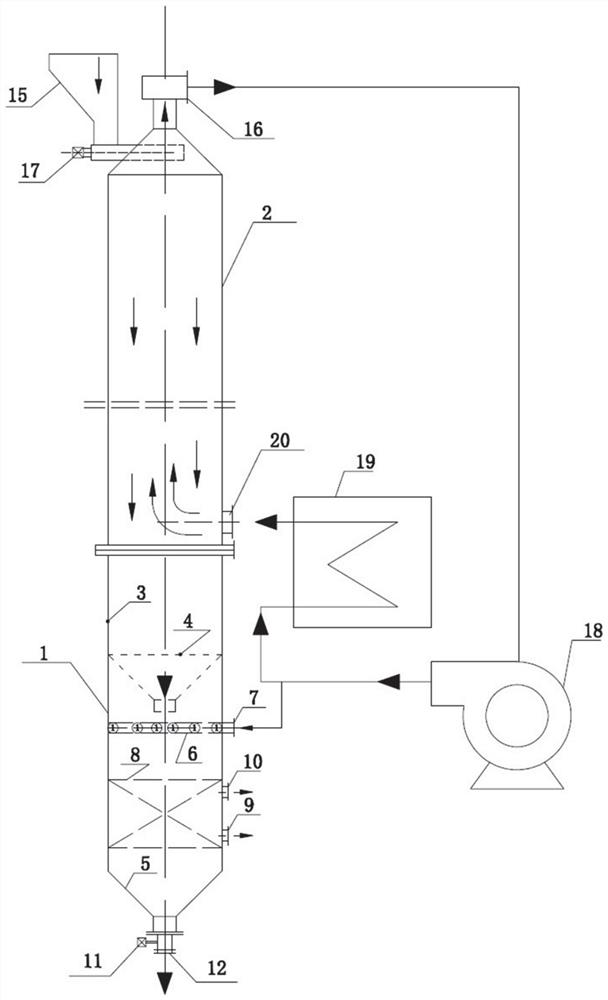

Embodiment 2

[0071] Wet coking coal with an average moisture content of 14% for ramming coke ovens, in which the largest coal particle size is not greater than 7mm, and the weight ratio of fine coal powder with a particle size below 0.2mm is 35%, and the particle size is 0.2mm~ The weight ratio of 3.0mm granular coal is 55%, and the minimum distillation temperature of the volatile fraction is 220°C. It is required to have an average moisture content of about 9% after the coal humidity control treatment, and the moisture in the coking coal should be about 9%. The deviation of the distribution consistency is less than 2%, and the processing capacity of a single set of coal humidity control device is 100 tons / hour.

[0072] The characteristic of wet coking coal that needs humidity control is that the average moisture content of wet coking coal is 14%, among which the moisture in fine coal powder is the highest, and its moisture content does not exceed 16%, including external moisture and inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com