Unsteady-state feedforward adjusting method for low-NOx coke oven heating gas, and coke oven

A regulation method and a non-steady-state technology, which are applied in the low-NOx coke oven heating gas feedforward regulation, non-steady state, coke oven field, to achieve the effects of simple structure, reduction of cross-leakage, reduction of coking energy consumption and flue gas NOx content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

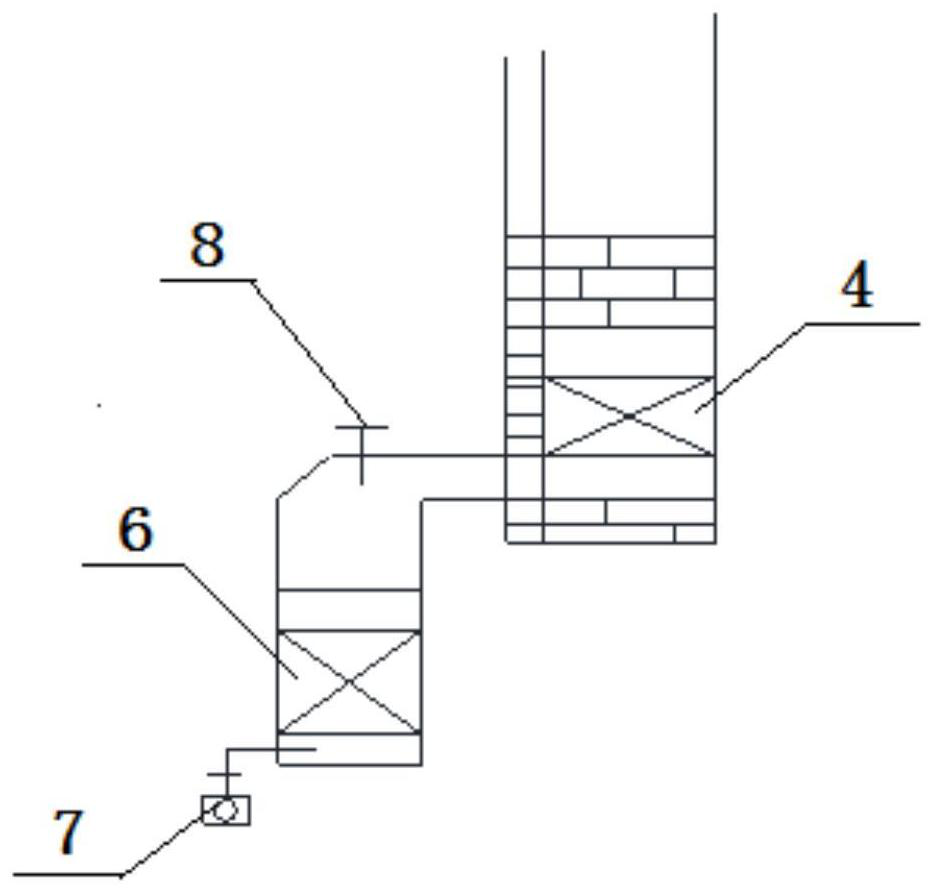

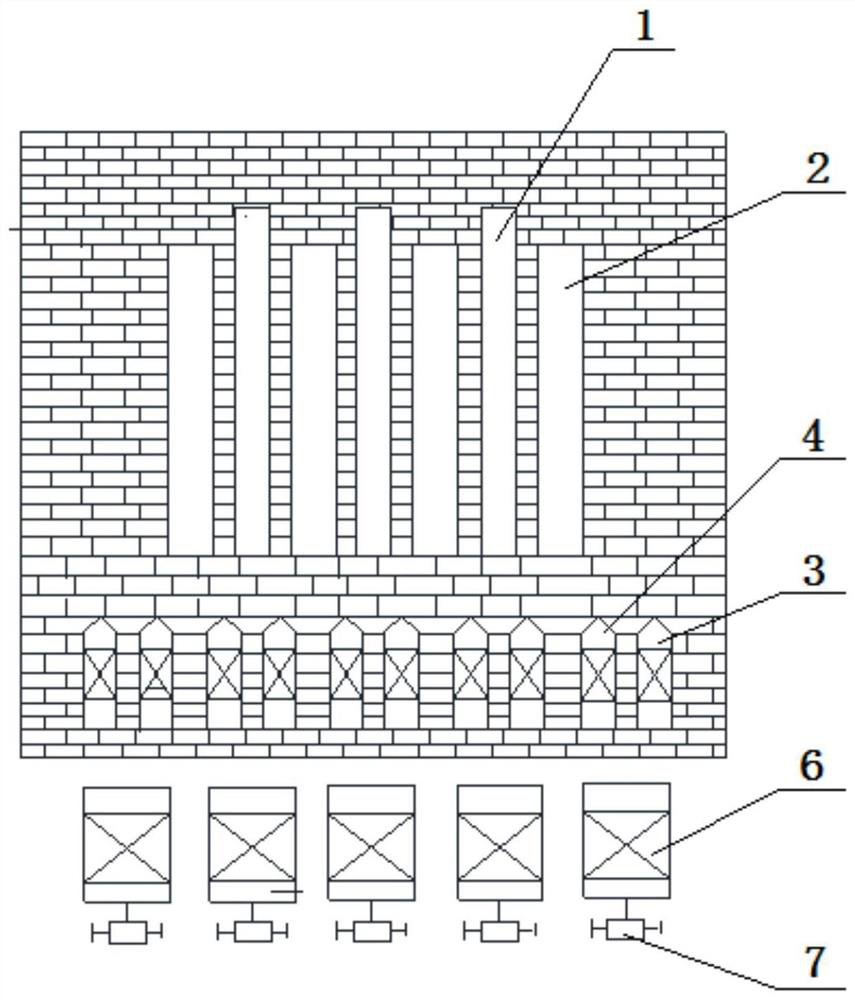

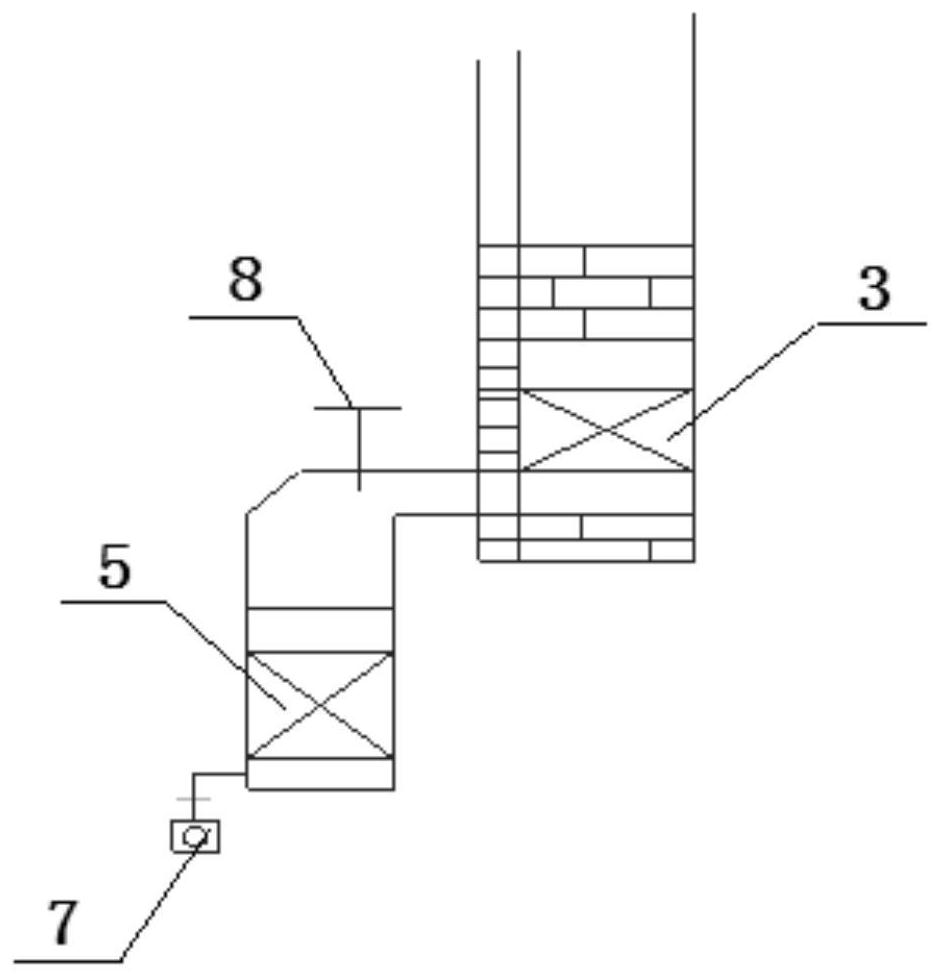

[0039] This embodiment discloses an unsteady, low NO x Coke oven heating gas feed-forward regulation coke oven, such as Figure 1-4 As shown, it includes a plurality of 10 coking units arranged side by side, and the coking unit includes a 10-hole carbonization chamber 1, a combustion chamber 2, a heat storage chamber, a gas heat storage reactor 5, an air heat storage reactor 6 and a reversing valve 7;

[0040] The carbonization chamber 1 and the combustion chamber 2 are arranged at intervals along the longitudinal direction of the coke oven, and a heat storage chamber is arranged below the carbonization chamber 1 and the combustion chamber 2, and the heat storage chamber is divided into a gas heat storage chamber 3 and an air heat storage chamber by a partition wall. Chamber 4: the partition wall of the regenerator is built with the same silica brick as the wall of the carbonization chamber, so as to ensure the same expansion of the wall of the regenerator and the carbonizati...

Embodiment 2

[0048] Unsteady, low NOx coke oven heating gas feed-forward adjustment system and furnace structure, including: carbonization chamber 1, combustion chamber 2, gas regenerator 3, air regenerator 4, gas regenerator 5, air storage Thermal reactor 6, reversing valve 7.

[0049] The carbonization chamber and the combustion chamber are alternately arranged along the longitudinal direction of the coke oven, and the regenerator is connected to the combustion chamber through a chute; every 10 carbonization chambers, combustion chambers and corresponding regenerators constitute a coking unit.

[0050] The regenerator is divided into a gas regenerator and an air regenerator through a partition wall. The gas regenerator is connected to the gas outlet of the fire passage through a chute, and the air regenerator is connected to the air outlet of the fire passage through a chute. connected.

[0051] The gas heat storage chamber is connected with the gas heat storage reactor, the air heat st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com