Preparation method of corn stigma polysaccharide and application of corn stigma polysaccharide in hypoglycemic products

A technology of corn silk polysaccharide and corn silk, which is applied in the extraction field, can solve the problems of large solvent consumption, complex solvent consumption, large solvent consumption, etc., and achieve the effects of improving extraction efficiency, good hypoglycemic effect and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

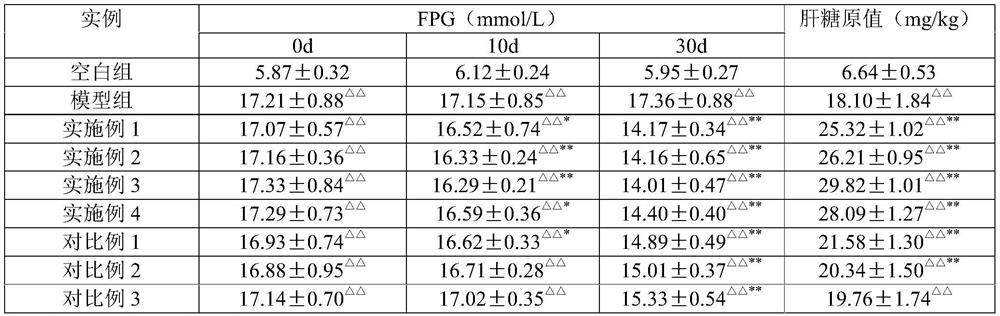

Examples

Embodiment 1

[0037] A preparation method of corn silk polysaccharide, comprising the following steps:

[0038] (1) pre-treatment: sieving after corn silk cleaning, drying, pulverization, obtaining corn silk powder, the corn silk powder is 95% ethanol with mass fraction (the weight volume ratio of corn silk powder and ethanol is 1: 3g / mL) dipping, impurity removal, after repeating three times, obtain the corn silk powder after degreasing;

[0039] (2) extraction: adding water and composite protease (the selected weight ratio of the composite protease is 3:1 papain and ficin by weight ratio of the corn silk powder after the defatting, the weight ratio of the corn silk powder and water, the composite protease is 1: 15:0.001), soaked for 8 hours, heated to 55 °C for the first time for extraction, and after cooling, added bromelain and 10% ethanol solution by weight again (the weight-volume ratio of defatted corn silk powder to solution A and bromelain was 1:5:0.001), soaked for 12h, heated to...

Embodiment 2

[0043] A preparation method of corn silk polysaccharide, comprising the following steps:

[0044](1) pre-treatment: sieving after corn silk cleaning, drying, pulverization, obtaining corn silk powder, the corn silk powder is 95% ethanol with mass fraction (the weight volume ratio of corn silk powder and ethanol is 1: 4g / mL) dipping, impurity removal, after repeating three times, obtain the corn silk powder after degreasing;

[0045] (2) extraction: adding water and composite protease (the weight ratio of composite protease is 6:1 papain and ficin, the weight ratio of corn silk powder and water, composite protease is 1: 25:0.003), soaked for 12h, first heated to 50°C for extraction, and after cooling, added bromelain and 15% ethanol solution by weight again (the weight-volume ratio of defatted corn silk powder to solution A and bromelain was 1:10:0.002), soaked for 8h, heated to 50°C for the second time for extraction, the extraction step was carried out under ultrasonic condi...

Embodiment 3

[0049] A preparation method of corn silk polysaccharide, comprising the following steps:

[0050] (1) pre-treatment: sieving after corn silk cleaning, drying, pulverization, obtaining corn silk powder, the corn silk powder is 95% ethanol with mass fraction (the weight volume ratio of corn silk powder and ethanol is 1: 3.5g / mL) dipping, impurity removal, after repeating three times, obtain the corn silk powder after degreasing;

[0051] (2) extraction: adding water and composite protease to the degreasing corn silk powder material (complex protease selection weight ratio is papain and ficin protease of 5:2, the weight ratio of corn silk powder material and water, composite protease is 1: 20:0.002), soaked for 10h, heated to 50°C for the first time for extraction, and after cooling, added bromelain and 15% ethanol solution by weight again (the weight-volume ratio of defatted corn silk powder to solution A and bromelain was 1:8:0.001), soaked for 10h, heated to 45°C for the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com