Process for continuously producing m-xylylenediamine

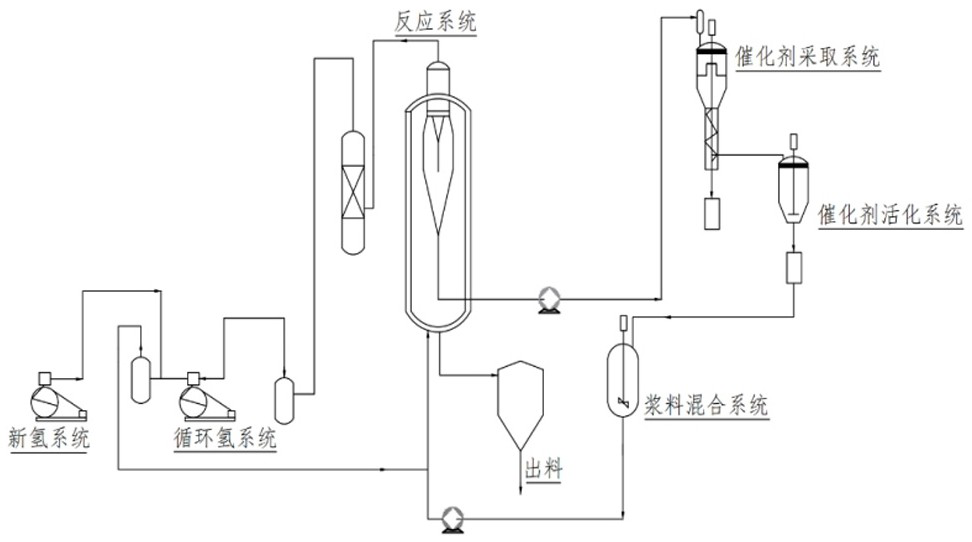

A m-xylylenediamine and isophthalonitrile technology, which is applied in the field of continuous m-xylylenediamine production, can solve the problems of low m-xylylenediamine selectivity, discontinuous operation, and low production efficiency. , to achieve the effect of easy control, shortening time and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

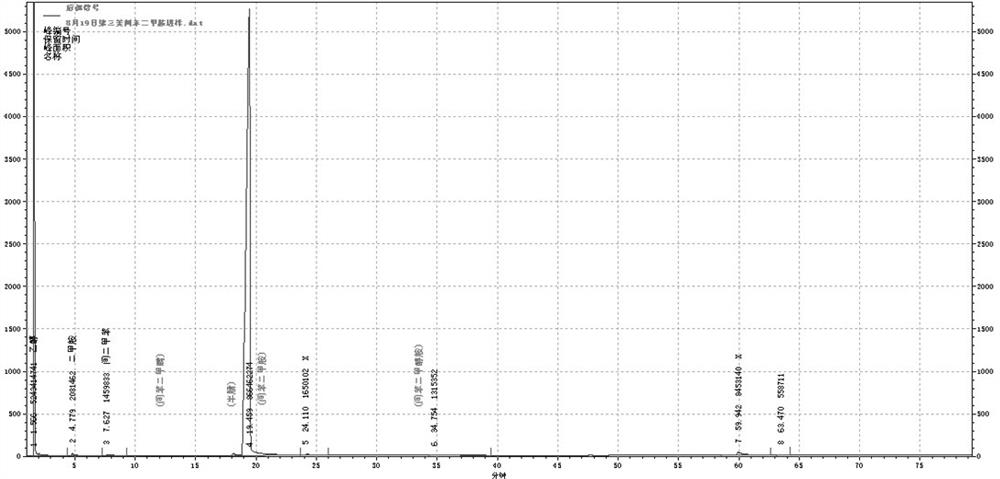

[0024] According to the production process of the present invention, after the content of isophthalonitrile and the content of m-xylylenediamine in the original solution after the reaction is measured by a gas chromatograph, the specific test results are shown in figure 2 .

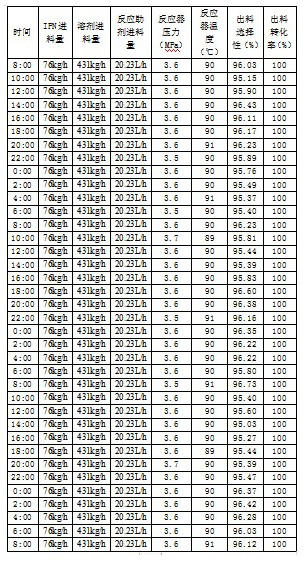

[0025] According to the method of the present invention, after the IPN is mixed with the solvent, the reaction assistant and the catalyst, a constant flow pump is added to the reactor, and the reaction is carried out continuously in the reactor under the uniform and stable force of hydrogen, and the main reaction data is the calibration for 72 hours. and running continuously:

[0026]

[0027] Conclusion: The production process can be continuously produced, has high production efficiency, and can be controlled and safely produced, so that the conversion rate of isophthalonitrile is 100%, and the selectivity of m-xylylenediamine is more than 95%. At the same time, the consumption of catalyst is reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com