Method for producing hydrogen peroxide based on photocatalysis of cadmium-based colloidal quantum dots and application

A colloidal quantum dot and quantum dot technology are applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen peroxide, etc., to achieve good application prospects, excellent photocatalytic hydrogen peroxide production performance, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

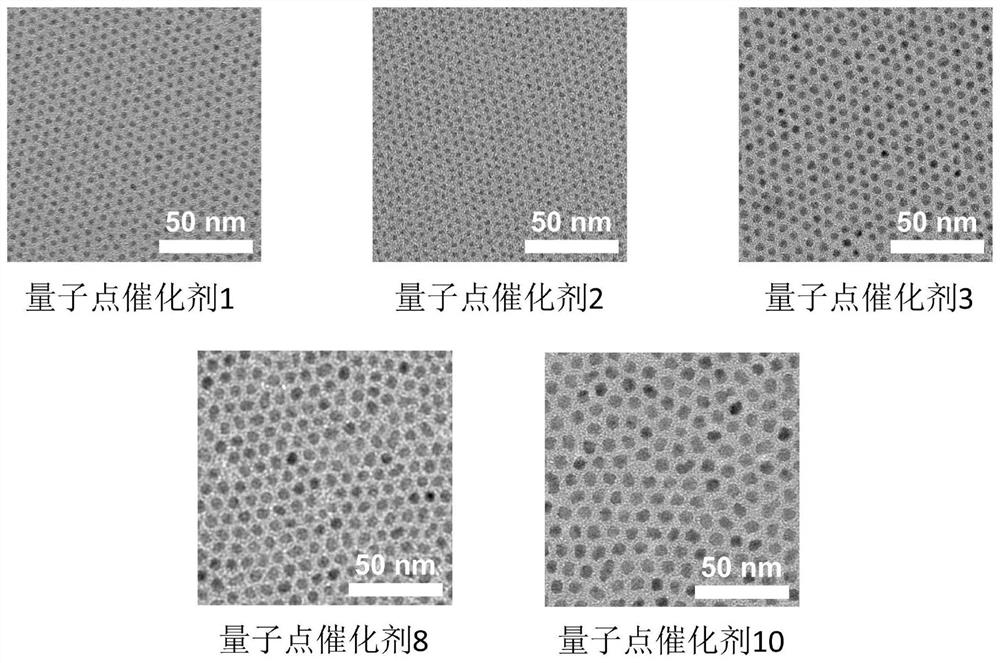

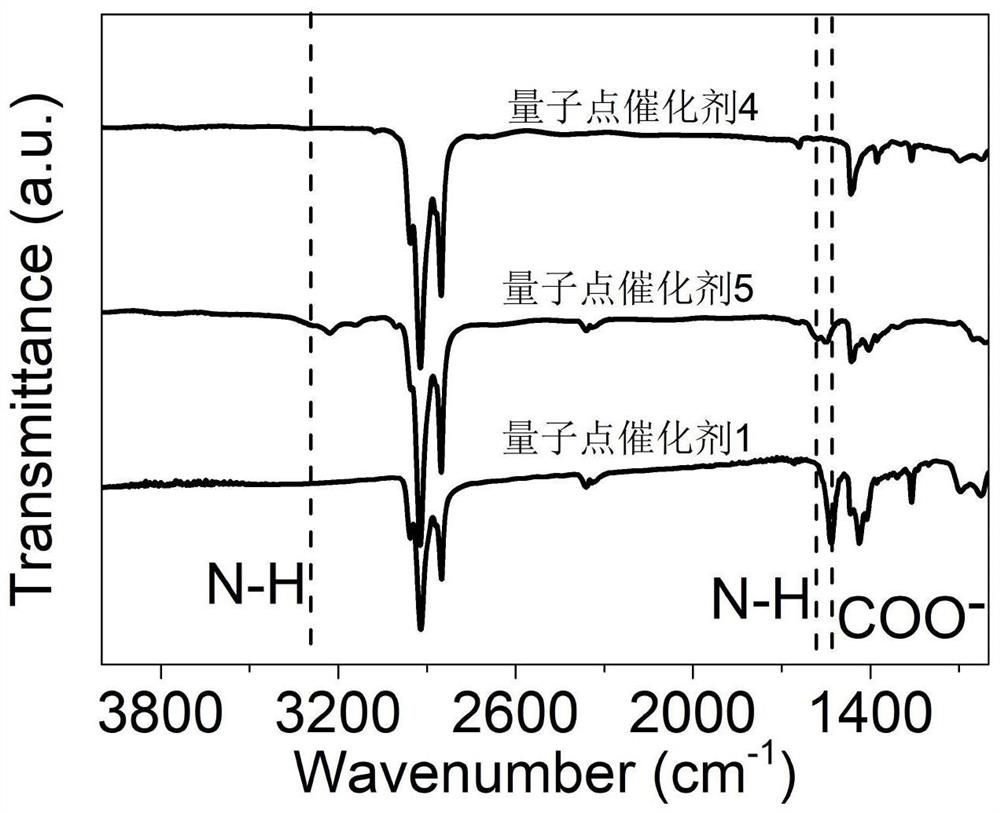

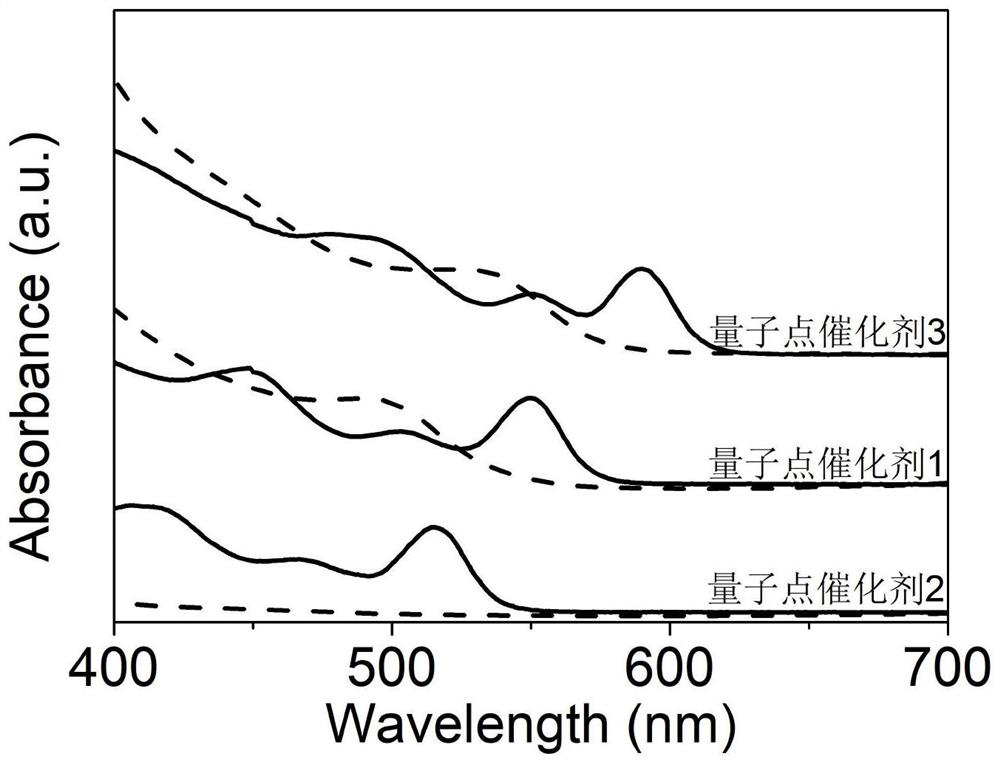

[0030] The invention discloses a preparation method of a quantum dot catalyst for photocatalytic production of hydrogen peroxide. The cadmium selenide quantum dots are synthesized by a thermal injection method, and cadmium sulfide and zinc sulfide shell layers are wrapped after purification. The specific preparation steps are:

[0031] 1) The quantum dot precursor is added to the three-necked flask; the precursor placed in the three-necked flask is cadmium oxide, tetradecanoic acid / stearic acid and octadecene, and the amount of cadmium oxide and acid and the type of acid are given by The catalyst required to synthesize the quantum dots is determined.

[0032] 2) the material in the step 1) is exhausted under an argon atmosphere, then the temperature is maintained until the solution is clear and transparent, and then the temperature is lowered to maintain; inject the selenium powder-octadecene suspension into the obtained transparent solution, and sample and detect at intervals,...

Embodiment 1

[0037] Embodiment 1: a kind of preparation method of quantum dot catalyst for photocatalytic production of hydrogen peroxide

[0038] (1) take by weighing 0.0128g cadmium oxide, 0.057g tetradecanoic acid, 4mL octadecene and place in three-necked flask;

[0039] (2) the material in the step (1) was exhausted for 10min under an argon atmosphere, then the temperature was raised to 280°C and maintained until the solution was clear and transparent, and then the temperature was lowered to 240°C to maintain;

[0040] (3) Inject 0.6mL 0.1M selenium powder-octadecene suspension into the transparent solution obtained in step (2) and time it, sampling and detecting at intervals, add 0.1mL 0.1M selenium powder-octadecene in 12min suspension. The reaction was stopped for 20 min. After the obtained quantum dot solution was cooled, 1.5 mL of the quantum dot solution was added to a 4 mL glass bottle, 2.5 mL of acetone was added to precipitate, the precipitate was centrifuged at 7500 r / min, the...

Embodiment 2

[0042] A preparation method of a quantum dot catalyst, comprising the following steps:

[0043] (1) take by weighing 0.0128g cadmium oxide, 0.057g tetradecanoic acid, 4mL octadecene and place in three-necked flask;

[0044] (2) the material in the step (1) was exhausted for 10min under an argon atmosphere, then heated to 280°C and maintained until the solution was clear and transparent, and then cooled to 250°C to maintain;

[0045] (3) inject 0.7mL of 0.1M selenium powder-octadecene suspension into the transparent solution obtained in step (2) and time it, set the maintenance temperature to 230°C, stop the reaction after 1min, and wait for the obtained quantum dot solution Cool, take 1.5mL of quantum dot solution into a 4mL glass bottle, add 2.5mL of acetone to precipitate, centrifuge the precipitate at 7500r / min, pour off the supernatant, add 0.5mL of toluene to dissolve and add 0.005mL of decanoic acid to heat until clear, 0.75 mL of methanol was added for precipitation, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com