3D printing metal base material with polydopamine-mesoporous bioactive glass composite coating as well as preparation method and application of 3D printing metal base material

A bioactive glass, 3D printing technology, applied in coating, metal material coating process, drug delivery, etc., can solve problems such as disadvantage, increased coating surface roughness, uncontrollable reaction, etc., and achieve good biocompatibility , the effect of improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

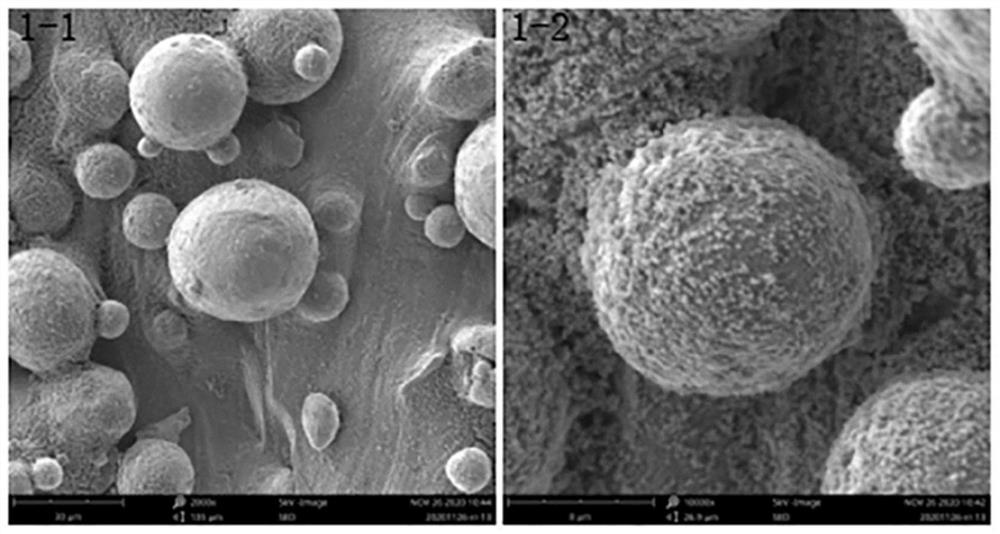

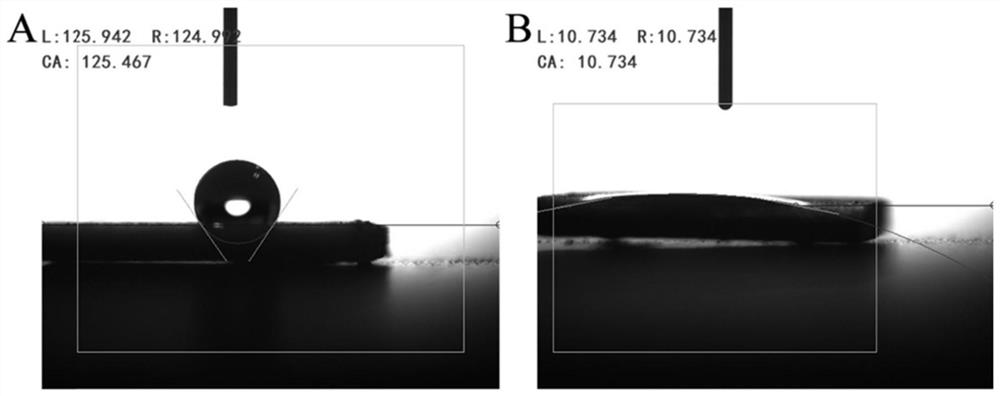

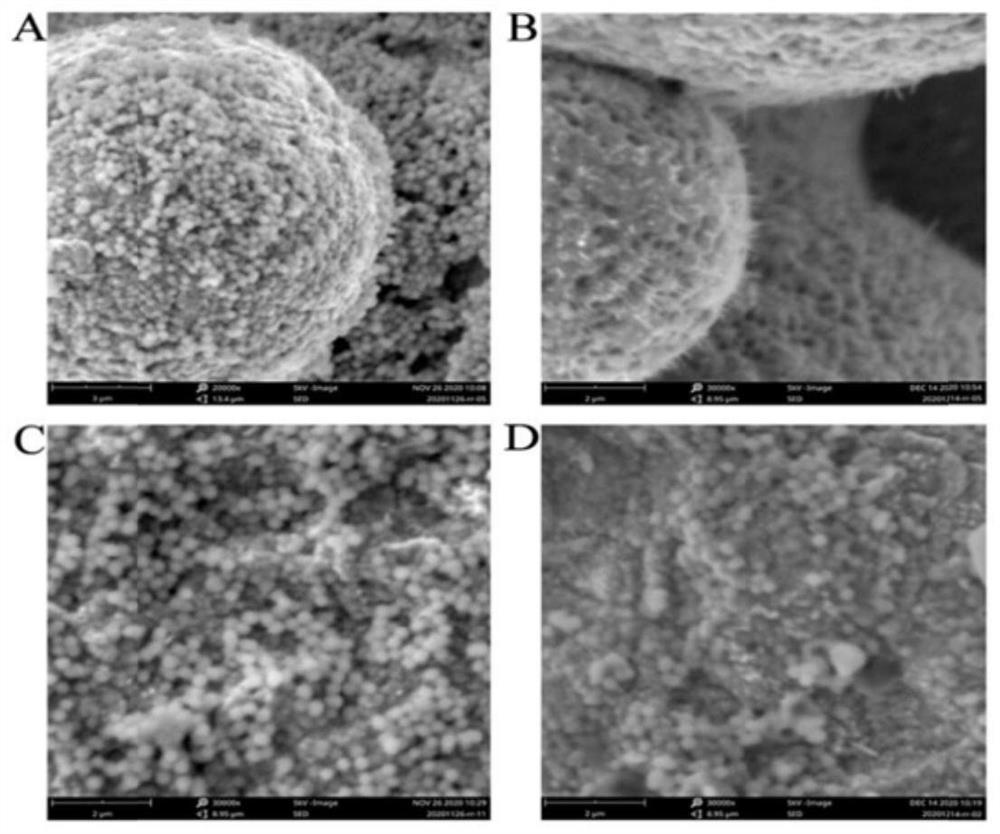

[0026] This embodiment provides a method for preparing a 3D printed metal substrate with a polydopamine-mesoporous bioactive glass composite coating, including the following steps:

[0027] (1) Pretreatment of 3D printed metal substrates: 1 cm × 2 cm 3D printed titanium sheets were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 15 min, and then the 3D printed Ti sheets were placed in a 40°C oven to dry. 10mL HF, 40mL HNO 3 and 50mL H 2 O is configured as a pickling solution, and the 3D printed Ti sheet is immersed in the pickling solution for 50s. After taking it out, rinse it with absolute ethanol to remove the residual acid solution on the surface, and dry it in an oven for use.

[0028] (2) Preparation of MBG: Add 4g of cetyltrimethylammonium bromide (CTAB) into 220ml of deionized water and 104ml of anhydrous ethanol mixed solution, stir until the solution is clear and transparent, then drop in 10ml of ammonia water, and stir for 30min . ...

Embodiment 2

[0031] This embodiment provides a method for preparing a 3D printed metal substrate with a polydopamine-mesoporous bioactive glass composite coating, including the following steps:

[0032] (1) Pretreatment of 3D printed metal substrates: 1 cm × 2 cm 3D printed titanium sheets were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 15 min, and then the 3D printed Ti sheets were placed in a 40°C oven to dry. 15mL HF, 50mL HNO 3 and 70mL H 2O is configured as a pickling solution, and the 3D printed Ti sheet is immersed in the pickling solution for 40s. After taking it out, it is rinsed with absolute ethanol to remove the residual acid solution on the surface, and it is dried in an oven for use.

[0033] (2) Preparation of MBG: Add 1 g of cetyl trimethyl ammonium bromide (CTAB) to a mixed solution of 220 ml of deionized water and 104 ml of absolute ethanol, stir until the solution is clear and transparent, then drop in 10 ml of ammonia water, and sti...

Embodiment 3

[0036] This embodiment provides a method for preparing a 3D printed metal substrate with a polydopamine-mesoporous bioactive glass composite coating, including the following steps:

[0037] (1) Pretreatment of 3D printed metal substrates: 1 cm × 2 cm 3D printed titanium sheets were ultrasonically cleaned with acetone, anhydrous ethanol, and deionized water for 15 min, and then the 3D printed Ti sheets were placed in a 40°C oven to dry. 5mL HF, 50mL HNO 3 and 75mL H 2 O is configured as a pickling solution, and the 3D printed Ti sheet is immersed in the pickling solution for 40s. After taking it out, it is rinsed with absolute ethanol to remove the residual acid solution on the surface, and it is dried in an oven for use.

[0038] (2) Preparation of MBG: Add 3g of cetyltrimethylammonium bromide (CTAB) to 220ml of deionized water and 104ml of anhydrous ethanol mixed solution, stir until the solution is clear and transparent, drop in 10ml of ammonia water, and stir for 30min . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com