Germanium multi-junction solar cell and preparation method thereof

A technology for solar cells and sub-cells, applied in the field of solar cells, can solve the problems of inability to achieve flexible thin film formation of germanium four-junction cells, difficult to significantly improve conversion efficiency, and high cost of GaAs substrates, so as to improve the photoelectric conversion efficiency and expand the forbidden band. The effect of width and high photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

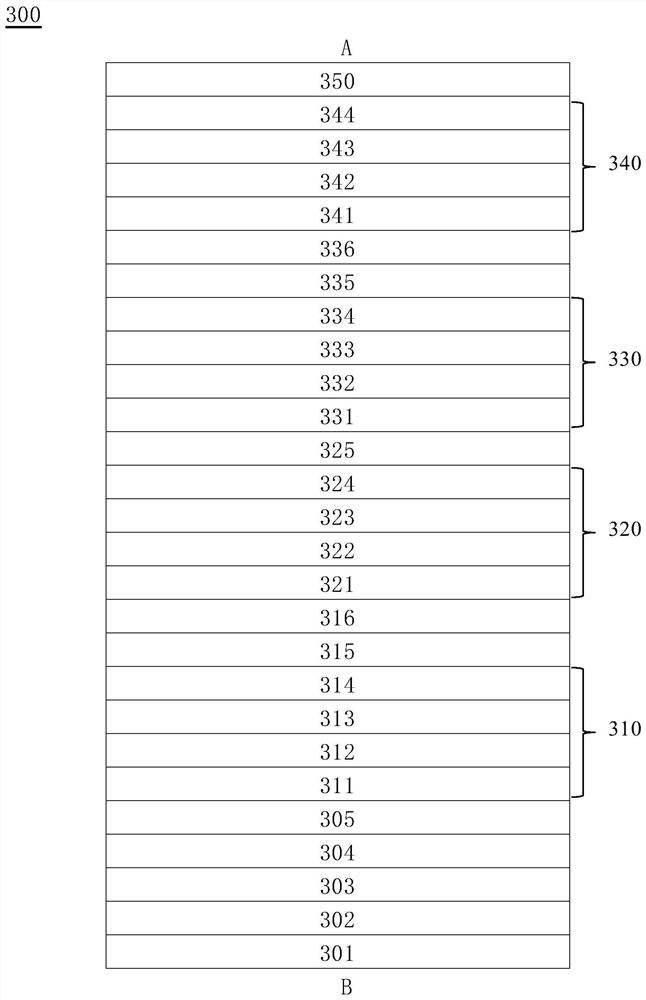

[0087] image 3 It is a schematic structural diagram of a germanium four-junction solar cell in preparation according to another embodiment of the present invention. Figure 4 is prepared image 3 Schematic diagram of the structure of the germanium quadruple junction solar cell. This example and figure 2 The structure of the four-junction solar cell 200 is basically the same, the difference is that the sacrificial layer structure is added in this embodiment, and the four-junction solar cell can be peeled off from the hard Si substrate by etching the sacrificial layer, and then connected to the flexible substrate. The flexible substrate can be thin-film metal such as copper, aluminum, or polyimide, thereby realizing the thin-film and flexible germanium four-junction solar cell.

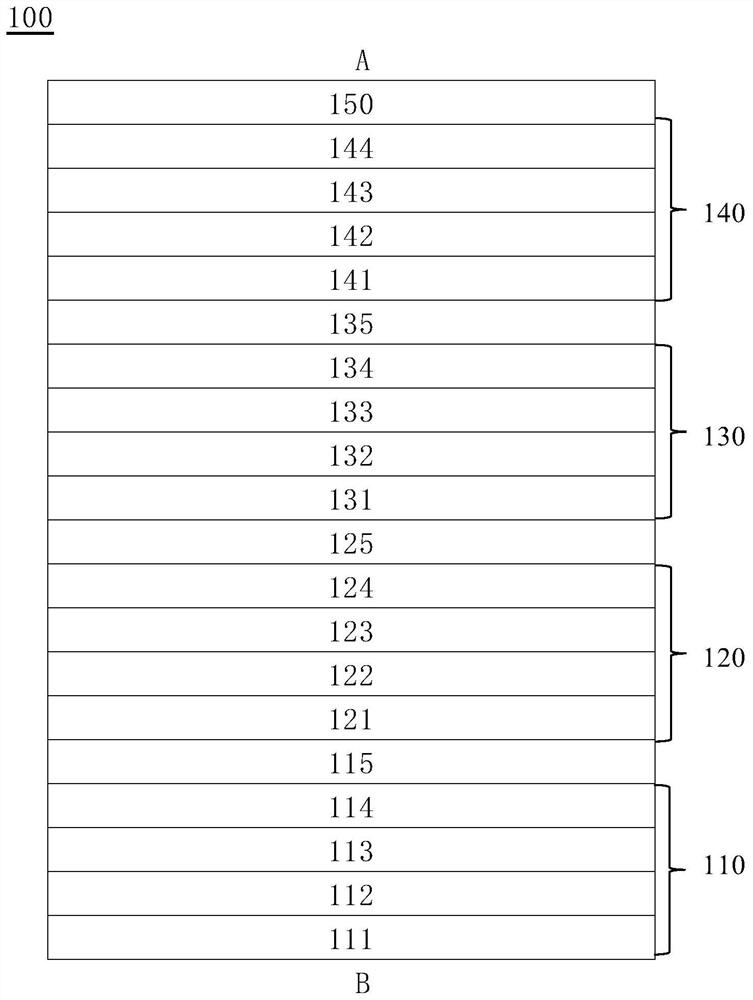

[0088] Specifically, as image 3 As shown, the germanium quad-junction solar cell 300 includes a Ge subcell 310 , an InGaAs subcell 320 , an InGaAsP subcell 330 and an InAlGaP subcell 340 epitaxia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com